- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 17:43

Back to list

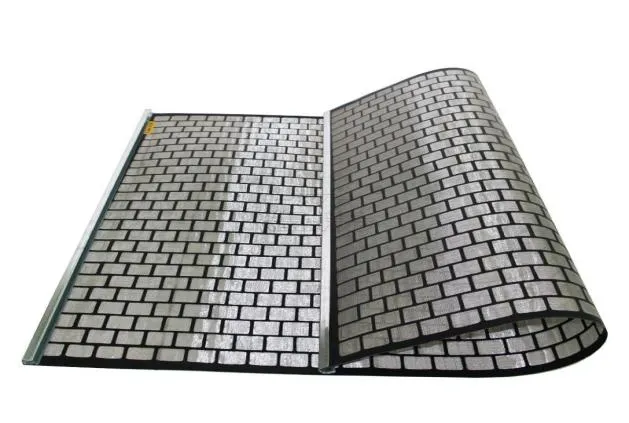

what is metal grating

Metal grating is an essential component in many industrial applications due to its robust structure and versatility. It finds usage in factories, warehouses, and even architectural projects. Understanding exactly what metal grating is and its benefits can give businesses an edge in selecting the right materials for their projects.

The expertise involved in metal grating selection extends beyond just choosing the material. Factors such as load capacity, span length, and the method of installation are crucial considerations. Engineers must assess the intended usage, atmospheric conditions, and frequency of load application to select grating that meets safety and operational efficiency standards. Using authoritative references can reinforce the trustworthiness of metal grating solutions. Industry-specific guidelines and certifications can assure users of the product's quality and performance. Additionally, working with reputable manufacturers or suppliers who adhere to standards such as ISO certification can add an extra layer of confidence. They ensure that the grating meets necessary technical and safety standards. Real-life applications showcase the significance and reliability of metal grating in various sectors. For instance, a power plant might utilize steel grating for maintenance walkways and platforms due to its ability to endure high temperatures and heavy-duty operations. In contrast, a coastal facility could opt for aluminum grating to combat the corrosive effects of saltwater exposure. Trustability is also enhanced by transparent communication regarding product performance and maintenance needs. Businesses aiming to integrate metal grating into their operations benefit from suppliers who provide detailed installation guides, maintenance schedules, and customer support to address potential issues or queries. In conclusion, metal grating is a versatile, robust solution adaptable to a myriad of industrial, commercial, and architectural needs. With a variety of materials and configurations available, metal grating provides an optimal combination of strength, flexibility, and durability. The successful implementation of metal grating requires careful consideration of the material properties, environmental conditions, and project-specific requirements, underscoring the critical role of industry expertise in selecting and applying this indispensable material.

The expertise involved in metal grating selection extends beyond just choosing the material. Factors such as load capacity, span length, and the method of installation are crucial considerations. Engineers must assess the intended usage, atmospheric conditions, and frequency of load application to select grating that meets safety and operational efficiency standards. Using authoritative references can reinforce the trustworthiness of metal grating solutions. Industry-specific guidelines and certifications can assure users of the product's quality and performance. Additionally, working with reputable manufacturers or suppliers who adhere to standards such as ISO certification can add an extra layer of confidence. They ensure that the grating meets necessary technical and safety standards. Real-life applications showcase the significance and reliability of metal grating in various sectors. For instance, a power plant might utilize steel grating for maintenance walkways and platforms due to its ability to endure high temperatures and heavy-duty operations. In contrast, a coastal facility could opt for aluminum grating to combat the corrosive effects of saltwater exposure. Trustability is also enhanced by transparent communication regarding product performance and maintenance needs. Businesses aiming to integrate metal grating into their operations benefit from suppliers who provide detailed installation guides, maintenance schedules, and customer support to address potential issues or queries. In conclusion, metal grating is a versatile, robust solution adaptable to a myriad of industrial, commercial, and architectural needs. With a variety of materials and configurations available, metal grating provides an optimal combination of strength, flexibility, and durability. The successful implementation of metal grating requires careful consideration of the material properties, environmental conditions, and project-specific requirements, underscoring the critical role of industry expertise in selecting and applying this indispensable material.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024