- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

What is Steel Grating? - Overview, Types, and Applications

What is Steel Grating?

What is Steel Grating?

The most prevalent types of steel grating are welded grating, press-locked grating, and swage-locked grating. Welded grating is created by welding the cross bars to the load-bearing bars, offering robust structural integrity and stability. Press-locked grating is manufactured by pressing cross bars into the load bars without welding, allowing for a lighter product suitable for lighter loads. Finally, swage-locked grating involves locking the cross bars into the load bars through a swaging process, resulting in a high-strength solution for heavy-duty applications.

what is steel grating

One of the primary advantages of steel grating is its ability to provide slip resistance and safety in industrial environments. The open structure of grating allows for quick drainage and prevents water accumulation, reducing the risk of slips and falls. Additionally, the spacing between bars can be designed to accommodate specific needs, making it customizable for industrial applications, including walkways, platforms, and stair treads.

Moreover, steel grating is widely used in various sectors, including oil and gas, manufacturing, wastewater treatment, and construction. Its resistance to corrosion, especially when treated with coatings or made from stainless steel, ensures it can withstand harsh environmental conditions while maintaining its structural integrity.

In conclusion, steel grating is an essential component in many industries, offering safety, strength, and versatility. Its ability to adapt to different applications makes it a preferred choice for engineers and designers aiming to create durable and effective solutions in their projects. Whether used for flooring, platforms, or safety barriers, steel grating continues to be a vital element in modern infrastructure and industrial design.

-

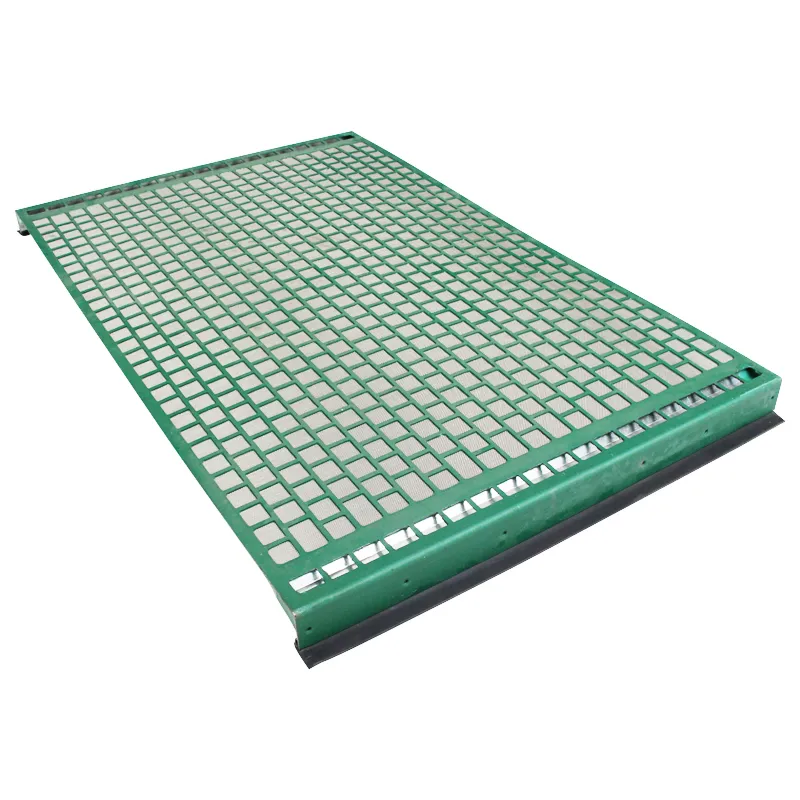

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024