- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

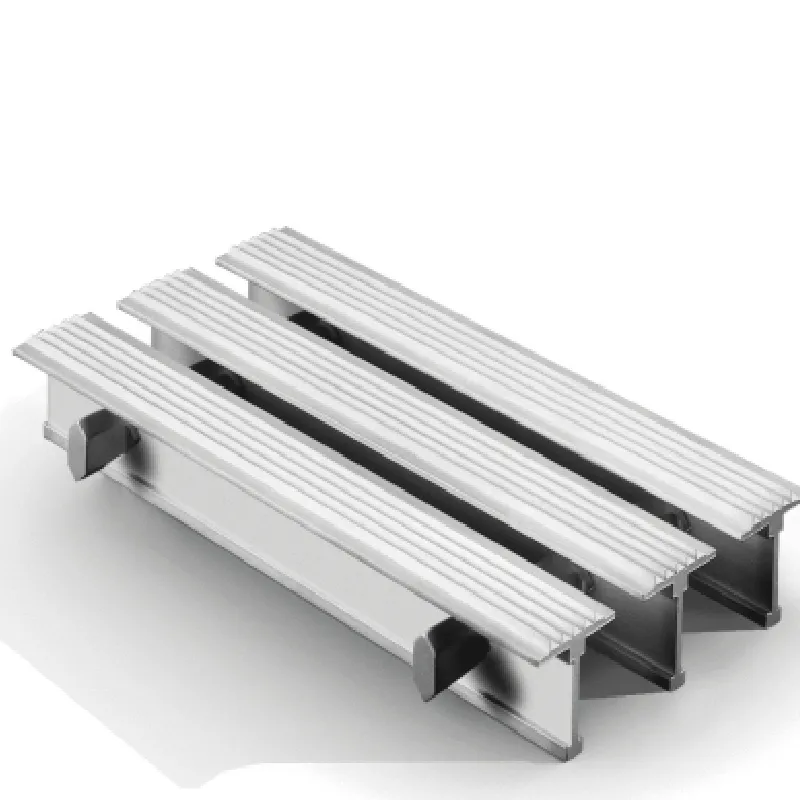

welded steel grating

The Versatility and Benefits of Welded Steel Grating

Welded steel grating is a widely used structural component in various industries due to its strength, durability, and versatility. Composed of a series of parallel steel bars welded together to form a grid-like pattern, this material offers an array of benefits, making it an essential choice for numerous applications.

One of the primary advantages of welded steel grating is its exceptional load-bearing capacity. This robust construction allows it to support heavy loads, making it ideal for use in environments such as industrial flooring, platforms, and walkways. Whether used in manufacturing facilities, warehouses, or construction sites, welded steel grating provides a safe and reliable surface for personnel and equipment.

In addition to its strength, welded steel grating is designed for high durability and longevity. The welded connections create a stable lattice structure that minimizes the risk of deformation or failure under stress. Moreover, it is resistant to corrosion when properly treated, prolonging its service life in challenging environments. This durability leads to lower maintenance costs and reduces the need for frequent replacements, making it a cost-effective choice in the long run.

welded steel grating

Another significant benefit of welded steel grating is its slip-resistant surface. The open design of the grating allows for excellent drainage, preventing the accumulation of water, debris, or hazardous materials that could lead to slipping. This feature enhances workplace safety, making it a preferred choice for areas that are exposed to wet or oily conditions.

Welded steel grating is highly customizable, which adds to its appeal across a variety of applications. Manufacturers can produce grating in different sizes, shapes, and finishes to meet specific needs. For instance, it can be manufactured with varying bar spacings or thicknesses, accommodating different load requirements or aesthetic preferences. Additionally, surface treatments such as galvanization or powder coating are available to further enhance its resistance to environmental factors and improve its appearance.

The installation of welded steel grating is generally straightforward, allowing for efficient setup in both new constructions and renovations. Its lightweight nature, combined with its prefabricated characteristics, simplifies the logistics of handling and placing the grating in position. This ease of installation can contribute to reduced labor costs and project timelines.

In conclusion, the application of welded steel grating is extensive, ranging from industrial flooring and safety walkways to architectural designs. Its combination of strength, durability, safety features, and versatility makes it a preferred option in multiple sectors. As industries continue to evolve, the demand for reliable and efficient materials like welded steel grating is likely to grow, making it a vital component in modern construction and infrastructure. Whether for functional use or aesthetic appeal, welded steel grating stands out as a practical solution to meet today’s engineering challenges.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024