- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 07, 2025 03:52

Back to list

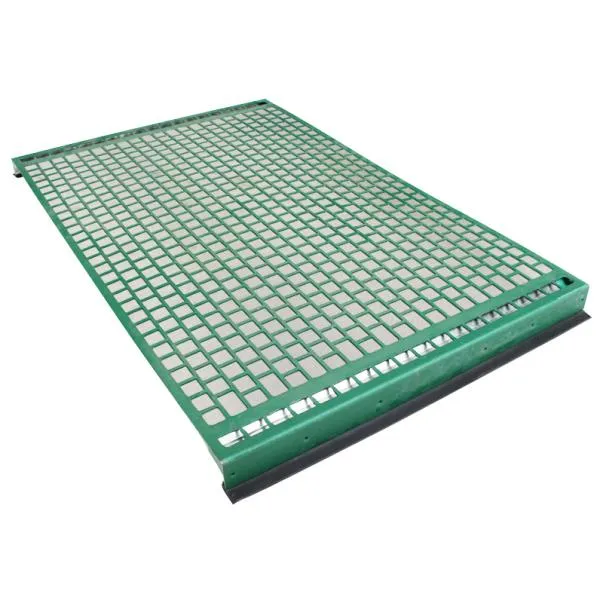

welded steel grating

Welded steel grating, a robust flooring solution, is specifically acclaimed for its durability, strength, and exceptional load-bearing capabilities. Many industrial and commercial enterprises have recognized these gratings as a critical safety feature in environments where heavy machinery, movement, and daily wear are prevalent. With increasing emphasis on workplace safety and efficiency, adopting welded steel grating not only ensures compliance with stringent safety standards but also enhances the operational efficiency of the entire facility.

Furthermore, many experts highlight the adaptability of welded steel gratings as a vital factor in their widespread adoption. They are customizable, with varying sizes and thicknesses to meet specific project needs without compromising their inherent strength and reliability. This flexibility allows businesses to implement a flooring solution that integrates seamlessly within their existing infrastructure. The economic viability of welded steel gratings should not be underestimated. While they may seem like an initial investment, the longevity, durability, and safety benefits they provide culminate in substantial cost savings over time. Businesses appreciate the reduced need for repairs and replacements, as well as the enhanced safety standards, which significantly lower potential compensation claims and insurance premiums. For anyone considering the implementation of welded steel grating, it is crucial to partner with reputable manufacturers known for producing high-quality products that adhere to industry specifications. An expertly crafted product not only meets the demands of high-stress environments but establishes trust and reliability within the infrastructure's foundation, fostering a safe and efficient working environment. Furthermore, through continuous dialogue with industry professionals specializing in welding and steel fabrication, the innovation in design and material use keeps evolving, ensuring that welded steel gratings remain at the forefront of industrial flooring solutions. As technologies advance, the focus on improving the strength, safety, and efficiency of these gratings underscores their importance in modern industrial and commercial applications.

Furthermore, many experts highlight the adaptability of welded steel gratings as a vital factor in their widespread adoption. They are customizable, with varying sizes and thicknesses to meet specific project needs without compromising their inherent strength and reliability. This flexibility allows businesses to implement a flooring solution that integrates seamlessly within their existing infrastructure. The economic viability of welded steel gratings should not be underestimated. While they may seem like an initial investment, the longevity, durability, and safety benefits they provide culminate in substantial cost savings over time. Businesses appreciate the reduced need for repairs and replacements, as well as the enhanced safety standards, which significantly lower potential compensation claims and insurance premiums. For anyone considering the implementation of welded steel grating, it is crucial to partner with reputable manufacturers known for producing high-quality products that adhere to industry specifications. An expertly crafted product not only meets the demands of high-stress environments but establishes trust and reliability within the infrastructure's foundation, fostering a safe and efficient working environment. Furthermore, through continuous dialogue with industry professionals specializing in welding and steel fabrication, the innovation in design and material use keeps evolving, ensuring that welded steel gratings remain at the forefront of industrial flooring solutions. As technologies advance, the focus on improving the strength, safety, and efficiency of these gratings underscores their importance in modern industrial and commercial applications.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024