- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

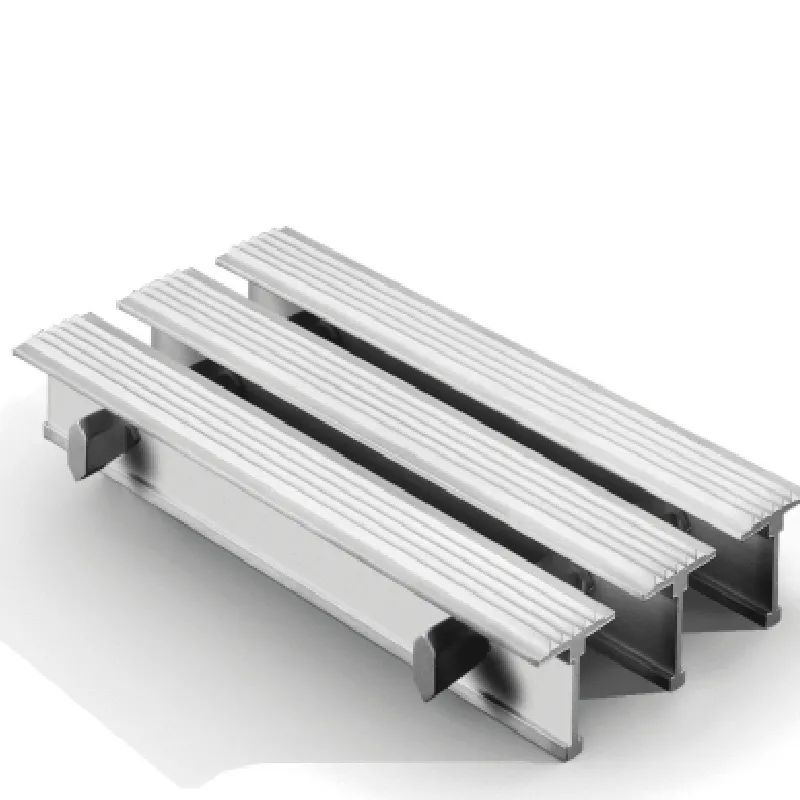

welded bar grating

Understanding Welded Bar Grating A Comprehensive Overview

Welded bar grating is a versatile and highly durable flooring and structural material that is used across various industries. Composed of a series of load-bearing bars welded to perpendicular cross bars, this product offers a combination of strength, stability, and lightweight characteristics, making it suitable for a wide range of applications. Whether utilized in industrial settings, commercial buildings, or municipal infrastructure, welded bar grating has become an essential component for achieving safety and functionality in elevated areas and platforms.

What Is Welded Bar Grating?

Welded bar grating is constructed by welding flat or serrated bars, which are typically made from steel or aluminum, at regular intervals to form a grid. This construction technique results in a material that is exceptionally strong and suited for heavy loads. The main bars, known as bearing bars, are spaced apart, allowing for efficient drainage and aeration while simultaneously providing adequate support. The cross bars, or transverse bars, are welded to the bearing bars to create a stable framework.

Applications of Welded Bar Grating

One of the primary applications of welded bar grating is in flooring systems for industrial plants, warehouses, and outdoor walkways. It is designed to allow for the safe passage of workers and equipment while providing excellent slip resistance. Additionally, welded bar grating is frequently used for platforms, catwalks, and stairways where its strength-to-weight ratio makes it an ideal choice. The open design of the grating ensures that debris falls through, making it easier to maintain cleanliness in high-traffic areas.

In the architectural realm, welded bar grating is becoming increasingly popular for aesthetic applications. Designers utilize it in façade systems, railings, and decorative elements due to its sleek appearance and customizable options. The grating can also be manufactured in various materials and coatings to enhance its resistance to rust and corrosion, making it suitable for outdoor environments and coastal areas.

welded bar grating

Advantages of Welded Bar Grating

One of the most significant advantages of welded bar grating is its structural integrity. The welding process creates a unified structure that distributes loads evenly, which is vital in preventing failures in high-load situations. Additionally, the durability of the materials used, coupled with proper surface treatments, ensures a long service life even when exposed to harsh conditions.

Another key benefit is maintenance. The open design of welded bar grating allows for easy cleaning as dirt and liquids can pass through the grid, reducing the accumulation of debris. This feature is especially important in environments where hygiene is critical, such as food processing plants and pharmaceutical facilities.

Moreover, the lightweight nature of welded bar grating means easier installation compared to traditional solid flooring. This can lead to significant labor savings and a decrease in associated costs. It can also be fabricated in various custom sizes and configurations, providing flexibility for different projects and applications.

Conclusion

Welded bar grating represents a perfect marriage of durability, functionality, and aesthetic appeal. With its broad scope of applications, ranging from industrial flooring to architectural designs, it continues to prove itself as an indispensable material in modern construction. As industries evolve and the demand for sustainable, efficient building solutions increases, welded bar grating stands out as a reliable choice that meets both performance and design requirements. For businesses and designers alike, embracing welded bar grating means investing in a product that prioritizes safety, longevity, and versatility.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024