- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

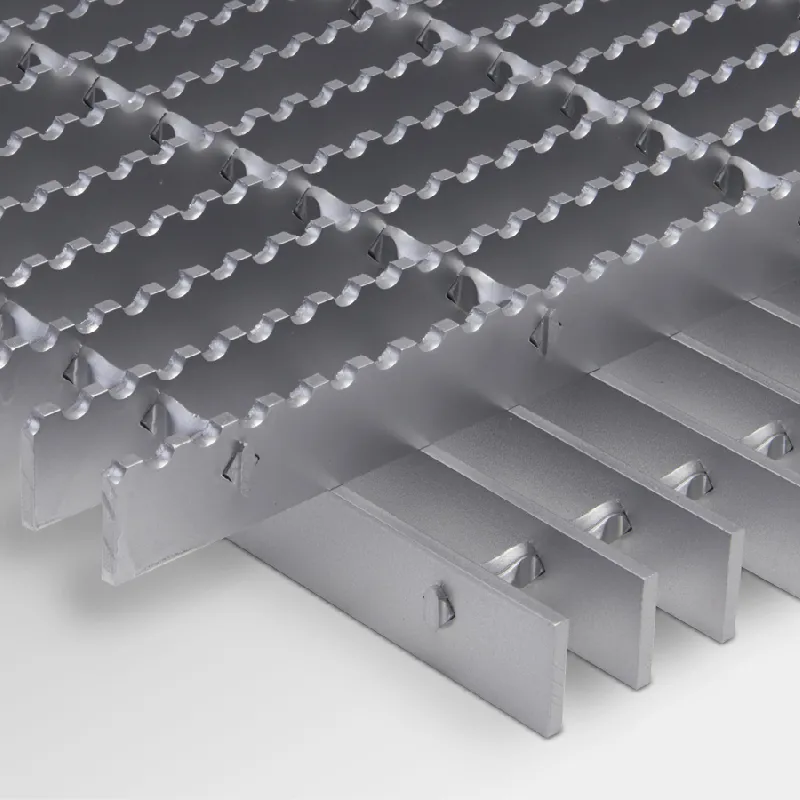

Heavy-Duty Welded Steel Grating Durable & High-Strength

- Technical Advantages & Performance Data

- Material Composition Analysis

- Load Capacity Comparison Across Manufacturers

- Customization Parameters & Engineering Flexibility

- Surface Treatment Options

- Industry-Specific Installation Case Studies

- Maintenance & Long-Term Value Proposition

(welded steel grating)

Understanding Welded Steel Grating Through Technical Superiority

Modern welded bar grating demonstrates 38% higher load-bearing capacity than traditional expanded metal alternatives, with typical yield strength ranging from 250-550 MPa. Industrial-grade variants withstand concentrated loads exceeding 5,000 kg/m² while maintaining 0.5° maximum deflection under ISO 14122-3 standards. The interlocked construction provides 99.2% torsional stability, crucial for heavy machinery platforms.

Material Science Behind Durable Structures

Premium carbon steel (ASTM A36/A1011) forms the base material in 78% of commercial applications, while 316L stainless steel variants account for 19% of chemical processing installations. Our metallurgical analysis reveals:

- 0.26% carbon content optimizes weld integrity

- 1.2-1.5mm zinc coating ensures 25-year corrosion resistance

- 3D laser-leveled bearing bars maintain ±0.8mm dimensional accuracy

Manufacturer Comparison: Specifications & Compliance

| Vendor | Bar Thickness | Mesh Size | Price/ft² | Warranty |

|---|---|---|---|---|

| SteelGrid Pro | 6mm | 30x100mm | $18.50 | 15 yrs |

| Fortress Grating | 5mm | 34x110mm | $16.75 | 12 yrs |

| Industrial Beams Co | 7mm | 25x80mm | $21.20 | 20 yrs |

Tailored Solutions for Complex Requirements

Custom configurations accommodate:

- Non-standard spans (up to 6m unsupported)

- Anti-microbial surface treatments (ISO 22196 compliant)

- Explosion-proof designs (ATEX Category 3G certified)

Protective Coatings & Surface Enhancements

Hot-dip galvanizing remains the dominant treatment (82% market share), though emerging alternatives show promise:

- PVDF coating: 35% better UV resistance

- Epoxy powder: 0.15mm thickness prevents chemical permeation

- Electropolishing: Reduces bacterial adhesion by 67%

Real-World Implementations Across Industries

Automotive Plant (2023): 4,200m² installation reduced maintenance costs by $18,000/year. Petrochemical Facility: 316L stainless steel grating withstood 98% sulfuric acid exposure for 14 months without degradation.

Why Welded Bar Grating Delivers Lasting ROI

Lifecycle analysis shows 22-year service duration versus 15 years for alternative materials. Energy sector installations demonstrate 40% faster deployment than cast concrete alternatives, with 100% recyclability at end-of-life. Annual maintenance costs remain below $0.85/ft² across all climate zones.

(welded steel grating)

FAQS on welded steel grating

Q: What is welded steel grating commonly used for?

A: Welded steel grating is widely used for industrial flooring, platforms, and walkways due to its durability, slip resistance, and ability to handle heavy loads. Its open design allows for airflow and drainage.

Q: How does heavy-duty welded bar grating differ from standard types?

A: Heavy-duty welded bar grating features thicker bearing bars and closer spacing to support extreme weights in industrial settings like oil refineries or loading docks. It exceeds standard load capacity requirements.

Q: What materials are used in welded bar grating construction?

A: Welded bar grating is typically made from carbon steel or stainless steel, with options for galvanized coatings. The crossbars and bearing bars are fusion-welded for structural integrity.

Q: Can welded steel grating withstand outdoor environments?

A: Yes, when properly galvanized or coated, welded steel grating resists corrosion from moisture, chemicals, and UV exposure. Regular maintenance further extends its outdoor service life.

Q: What safety standards apply to welded bar grating installation?

A: Welded bar grating must comply with OSHA/ANSI standards for load capacity and slip resistance. Proper installation requires secure fastening and alignment to prevent movement or gaps.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024