- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

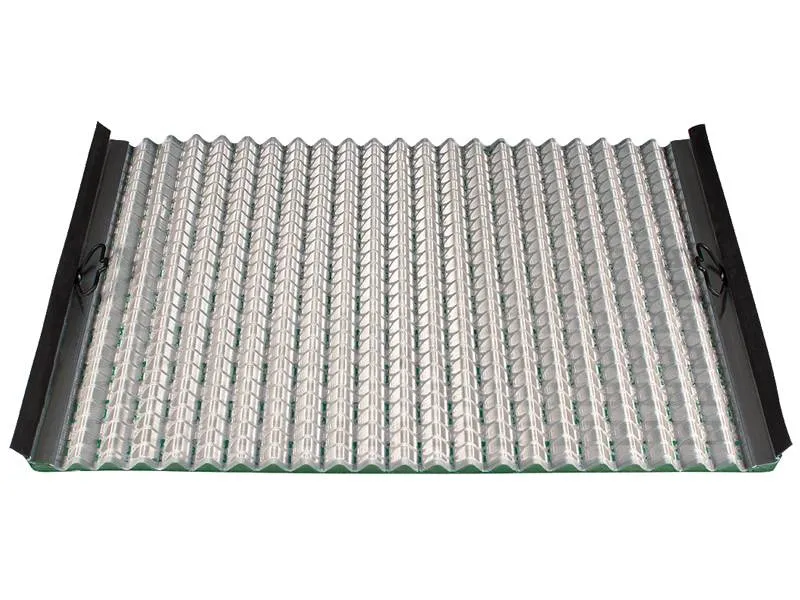

welded bar grating

Understanding Welded Bar Grating An Overview

Welded bar grating is a versatile and durable flooring solution widely used in various industries, including construction, manufacturing, and maintenance sectors. Comprising a series of longitudinal and cross-sectional bars, welded bar grating is created through a process of resistance welding, where the intersecting bars are fused together, resulting in a robust and stable grid. This unique construction method enables welded bar grating to support heavy loads and withstand harsh environmental conditions, making it an excellent choice for both indoor and outdoor applications.

One of the key advantages of welded bar grating is its strength. The welding process ensures that each joint is secure, providing a solid structure capable of enduring significant weight. As a result, it is commonly employed in applications such as industrial flooring, walkways, platforms, and stair treads, where safety and durability are paramount. Additionally, the spacing between the bars allows for efficient drainage, reducing the accumulation of water, oil, or debris, which can be critical in maintaining safety in high-traffic areas.

Another noteworthy benefit of welded bar grating is its low maintenance requirements. Unlike solid floorings, which may harbor contaminants and require extensive cleaning efforts, welded bar grating’s open design facilitates easy cleaning. Its materials, typically made from steel or aluminum, are resistant to corrosion, further enhancing its longevity and reliability.

welded bar grating

The versatility of welded bar grating is also evident in its availability in various materials, sizes, and configurations. Whether it is for a specific load-bearing requirement or aesthetic preferences, consumers can find tailored solutions to meet their needs. Steel gratings, for instance, are often used in heavy-duty applications, while aluminum gratings offer a lightweight and corrosion-resistant alternative suitable for more moderate uses.

Moreover, welded bar grating contributes to efficiency in terms of installation and design flexibility. The grating can be easily cut to fit a specific space or custom-designed to accommodate particular specifications, making it a practical choice for architects and engineers. Its lightweight nature simplifies transportation and handling, which can significantly reduce installation costs and time.

In conclusion, welded bar grating is a reliable, durable, and versatile flooring solution that meets the demanding requirements of various industries. Its strength, low maintenance, and ease of installation make it a preferred choice for professionals seeking effective and efficient floor systems. As industries continue to evolve and demand innovative solutions, welded bar grating stands out as a trustworthy option that blends functionality with practicality.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024