- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Calculating Steel Grating Weight Per Square Foot for Construction Projects

Understanding the Weight of Steel Grating per Square Foot

Steel grating is an essential component in various industrial applications, offering durability, strength, and versatility. It is commonly used in construction projects, walkways, platforms, and drainage covers. One of the critical factors to consider when selecting steel grating for any application is its weight per square foot, which significantly affects both installation and overall structural integrity.

The weight of steel grating is primarily determined by its material composition, thickness, and design. Typically, steel grating is made from carbon steel, stainless steel, or alloy steels. Among these, carbon steel is the most common due to its balance of strength and cost-effectiveness. On average, carbon steel grating can weigh between 1.5 to 3.0 pounds per square foot, depending on the gauge of the steel and the spacing of the bars.

Another factor influencing the weight of steel grating is its thickness. Thicker grating can support heavier loads and is often required in industrial settings where heavy equipment is in use. For instance, a thicker grating might weigh closer to 3.0 to 4.0 pounds per square foot, making it suitable for applications involving heavy machinery or significant traffic. Conversely, lighter grades of grating, used in residential or less demanding environments, may fall in the range of 1.0 to 2.0 pounds per square foot.

weight of steel grating per square foot

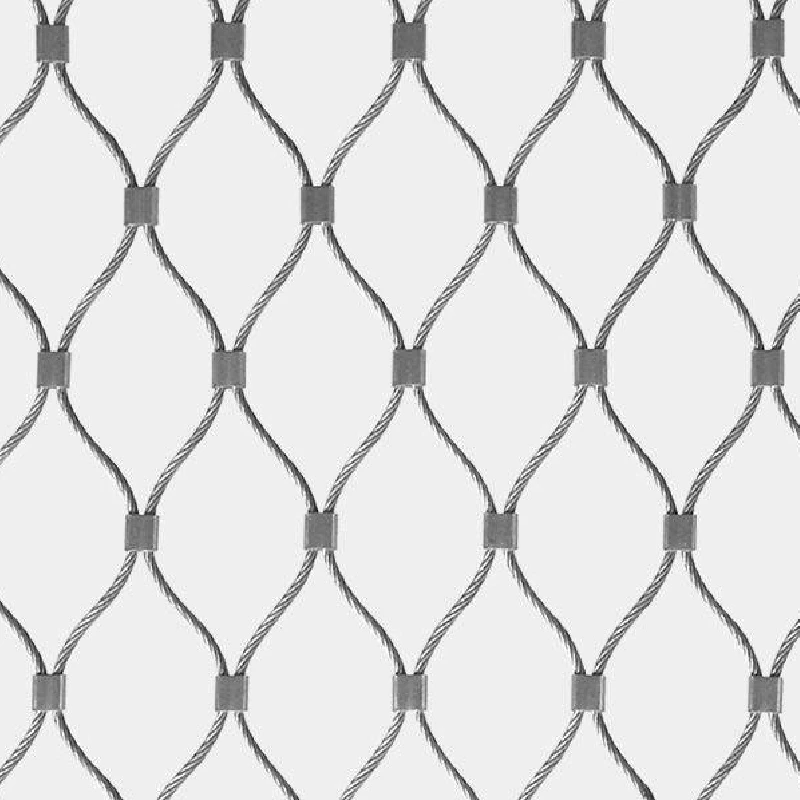

The design of the steel grating also plays a crucial role in its weight. There are various types of grating designs, including welded, press-locked, and swage-locked. Welded grating tends to be heavier due to the solid joints between the bars, while press-locked and swage-locked options might be lighter yet still offer adequate strength and support. When evaluating grating options, it's vital to consider not only the weight but also how the design can impact load distribution and safety.

Choosing the right weight of steel grating is essential for several reasons. First, it directly affects transportation costs; heavier grating can lead to higher shipping fees. Second, the installation process may vary based on weight, as heavier materials often require additional labor or equipment for handling. Lastly, the weight contributes to the overall safety and longevity of the installation — ensuring that the grating can withstand anticipated loads over time is crucial for preventing accidents and ensuring structural integrity.

In conclusion, understanding the weight of steel grating per square foot is vital for anyone involved in construction or industrial applications. When selecting steel grating, consider factors such as material type, thickness, design, and the specific requirements of your project. Ultimately, the right choice can enhance safety, efficiency, and durability, making it a key consideration in any project involving steel grating. It’s advisable to consult with manufacturers or experts in the field to ensure that the selected grating meets the specific needs and standards required for your application.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024