- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Understanding Costs and Factors Influencing Bar Grating Prices in Today's Market

Understanding Bar Grating Prices Factors and Insights

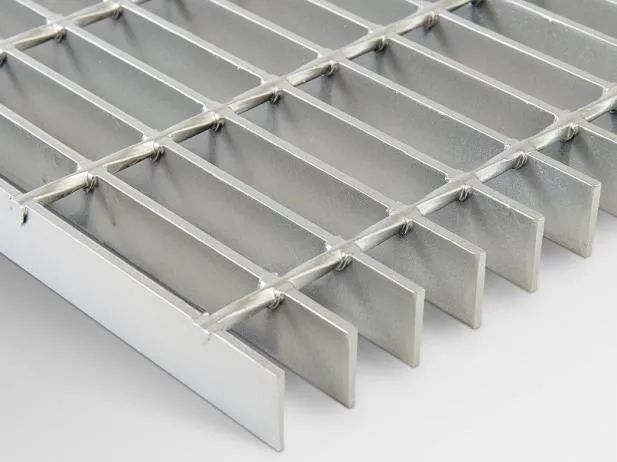

When it comes to architectural and industrial applications, bar grating serves as a vital component due to its strength, durability, and versatility. Composed of a series of bars that create a grid-like structure, bar grating is often used in flooring, walkways, platforms, and even as drains in various environments. However, one of the critical aspects that buyers must consider is the price, which can fluctuate based on several factors.

Types of Bar Grating

Bar grating comes in various types, and the material is one of the primary determinants of pricing

. The most common types include1. Steel Bar Grating Known for its high strength and durability, steel grating can handle heavy loads, making it suitable for industrial applications. Prices can vary based on whether it's galvanized, stainless steel, or carbon steel. 2. Aluminum Bar Grating Lighter than steel and corrosion-resistant, aluminum grating is ideal for environments that may not have heavy traffic loads. It generally has a higher cost due to the material's lightweight and resistance properties.

3. Fiberglass Reinforced Plastic (FRP) Grating Used mainly in corrosive environments, FRP is more expensive due to the manufacturing process and raw materials involved. However, its longevity in harsh conditions makes it a cost-effective choice in the long run.

Factors Influencing Prices

1. Material Costs As we have noted, the type of material directly impacts the price of bar grating. Steel prices fluctuate based on market demand and supply, while aluminum and fiberglass are also subject to similar market forces.

2. Manufacturing Processes The method of production can significantly affect the cost. Extruded grating, for example, may be more expensive than welded grating due to the complexity of the manufacturing process.

bar grating prices

3. Load Capacity The load-bearing capacity required for the grating will play a role in pricing. Heavy-duty gratings are typically more expensive as they require more robust materials and construction techniques to ensure safety and reliability.

4. Dimensions and Customization Standard sizes are often cheaper than custom-cut options. Therefore, if a project needs unique dimensions or special configurations, the cost may increase to accommodate manufacturing adjustments.

5. Screening and Finishing Additional features such as surface treatments for slip resistance or custom coatings can also affect pricing. Such enhancements are important for safety but add to the overall cost.

6. Supplier and Location The supplier you choose and the geographical location can impact pricing due to shipping costs and regional demand. Comparing prices from multiple suppliers can provide more cost-effective options.

Average Pricing

While prices can vary widely, steel bar grating often ranges from $1.50 to $5.00 per square foot. Aluminum options might be priced higher, typically between $4.00 and $10.00 per square foot. FRP grating can range from $6.00 to $15.00 per square foot, reflecting its specialized applications.

Conclusion

Understanding bar grating prices involves more than just looking at numbers. Buyers need to take into account the material, manufacturing processes, load capacity, and any customization requirements that may be needed for their specific applications. As always, obtaining multiple quotes and considering the long-term benefits of quality products can help in making informed decisions. With the right knowledge, businesses can optimize their expenditures while ensuring they choose the most effective bar grating solutions for their needs.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024