- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 04, 2025 02:33

Back to list

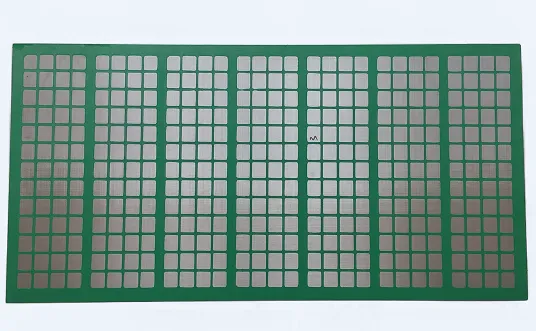

types of steel grating

Types of steel grating exhibit immense versatility and utility in various industrial and architectural applications. They are pivotal for their durability, strength, and adaptability to diverse environments. This article delves into the intricacies of different types of steel grating, offering an expert perspective on their applications, benefits, and selection criteria.

4. Heavy-Duty Steel Grating Designed to withstand extremely heavy loads, heavy-duty steel grating is fabricated using thicker bearing bars. This type is necessary for applications subject to vehicle traffic, such as highways, bridge decking, and airport runways. Its unparalleled strength ensures that even the heaviest machinery or vehicles can move safely without compromising the integrity of the grating. 5. Aluminum and Stainless Steel Grating While not exclusively a type of steel grating, the inclusion of aluminum and stainless steel gratings highlights the adaptability of material choice to specific environmental needs. Stainless steel grating offers superior resistance to corrosion and is the preferred choice in highly corrosive environments. Aluminum grating, on the other hand, provides a lightweight alternative with excellent corrosion resistance, ideal for marine applications where weight savings are crucial. When selecting the appropriate type of steel grating, several factors must be considered to ensure optimal performance and longevity. These factors include load requirements, environmental conditions, installation and maintenance costs, and aesthetical considerations. Consulting with industry experts or manufacturers can further enhance decision-making by providing tailored solutions and insights. The reliability of steel grating in providing safe, durable, and cost-effective solutions to complex engineering problems cannot be overstated. Its wide range of types caters to myriad applications, cementing its position as a crucial component in infrastructure and design worldwide. Companies investing in the right type of steel grating demonstrate a commitment to safety, innovation, and efficiency, reinforcing their status as leaders in their respective fields.

4. Heavy-Duty Steel Grating Designed to withstand extremely heavy loads, heavy-duty steel grating is fabricated using thicker bearing bars. This type is necessary for applications subject to vehicle traffic, such as highways, bridge decking, and airport runways. Its unparalleled strength ensures that even the heaviest machinery or vehicles can move safely without compromising the integrity of the grating. 5. Aluminum and Stainless Steel Grating While not exclusively a type of steel grating, the inclusion of aluminum and stainless steel gratings highlights the adaptability of material choice to specific environmental needs. Stainless steel grating offers superior resistance to corrosion and is the preferred choice in highly corrosive environments. Aluminum grating, on the other hand, provides a lightweight alternative with excellent corrosion resistance, ideal for marine applications where weight savings are crucial. When selecting the appropriate type of steel grating, several factors must be considered to ensure optimal performance and longevity. These factors include load requirements, environmental conditions, installation and maintenance costs, and aesthetical considerations. Consulting with industry experts or manufacturers can further enhance decision-making by providing tailored solutions and insights. The reliability of steel grating in providing safe, durable, and cost-effective solutions to complex engineering problems cannot be overstated. Its wide range of types caters to myriad applications, cementing its position as a crucial component in infrastructure and design worldwide. Companies investing in the right type of steel grating demonstrate a commitment to safety, innovation, and efficiency, reinforcing their status as leaders in their respective fields.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024