- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 17, 2025 18:25

Back to list

trench drain grate

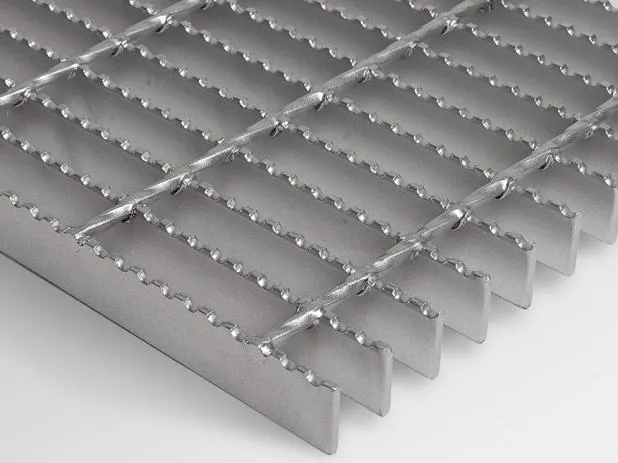

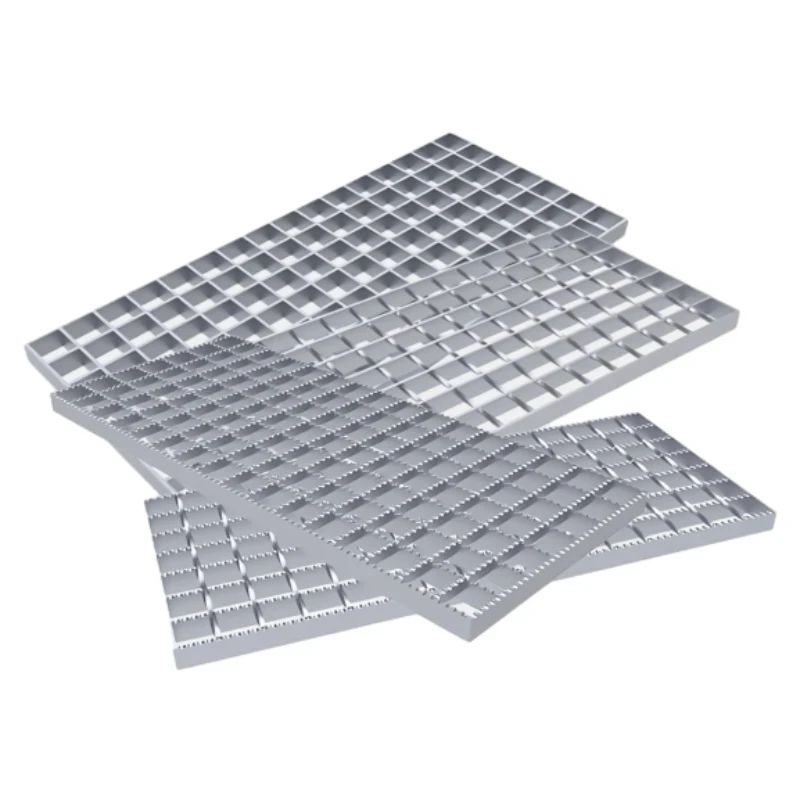

Trench drain grates, often perceived as simple infrastructural components, hold a critical yet uncelebrated role in flood prevention, public safety, and urban aesthetics. Manufactured from materials such as cast iron, stainless steel, and HDPE, these grates are engineered to meet varying drainage needs, from residential driveways to high-traffic industrial zones. My years of experience working with different types of trench drain installations have made it clear that choosing the right grate is paramount for optimal functionality.

An often-overlooked aspect of trench drain grates is their impact on safety. Poorly designed or incorrect grates can pose trip hazards, especially in pedestrian zones. Safety is a fundamental consideration in my approach to advising clients, meaning grate designs that feature anti-slip surfaces and flatter profiles are always preferred to mitigate risk. Additionally, choosing grates that ensure minimum risk of wearing down and maintaining slip-resistance over time contributes to a safe environment. Trench drain grates also contribute significantly to environmental sustainability. During rainfall, they capture surface runoff, reducing the risk of flooding and waterlogging. Advanced biological treatment systems, which integrate with trench drains, use specially coated grates to filter oily residues and other impurities from the water. This ensures cleaner water release into stormwater systems, underlining the importance of grates not just as components of drainage, but also as contributors to environmental protection. To ensure trustworthiness and authoritative advice, clients and professionals must rely on industry-certified products and adhere to local regulations that govern stormwater management. Partnering with manufacturers and suppliers who adhere to these standards not only ensures compliance but guarantees the performance quality of the trench drains. In conclusion, trench drain grates are more than just metal covers on drainage trenches. They are essential components that demand careful selection and maintenance to meet both functional and aesthetic needs. Understanding the complexities and requirements unique to each application allows professionals to optimize these systems for durability, efficiency, and visual integration. As an industry veteran committed to optimizing functionality and aesthetics in drainage solutions, my approach underscores the value of meticulous material selection and innovative design to leverage trench drain grates as not just infrastructural necessities, but as strategic enhancements to any project.

An often-overlooked aspect of trench drain grates is their impact on safety. Poorly designed or incorrect grates can pose trip hazards, especially in pedestrian zones. Safety is a fundamental consideration in my approach to advising clients, meaning grate designs that feature anti-slip surfaces and flatter profiles are always preferred to mitigate risk. Additionally, choosing grates that ensure minimum risk of wearing down and maintaining slip-resistance over time contributes to a safe environment. Trench drain grates also contribute significantly to environmental sustainability. During rainfall, they capture surface runoff, reducing the risk of flooding and waterlogging. Advanced biological treatment systems, which integrate with trench drains, use specially coated grates to filter oily residues and other impurities from the water. This ensures cleaner water release into stormwater systems, underlining the importance of grates not just as components of drainage, but also as contributors to environmental protection. To ensure trustworthiness and authoritative advice, clients and professionals must rely on industry-certified products and adhere to local regulations that govern stormwater management. Partnering with manufacturers and suppliers who adhere to these standards not only ensures compliance but guarantees the performance quality of the trench drains. In conclusion, trench drain grates are more than just metal covers on drainage trenches. They are essential components that demand careful selection and maintenance to meet both functional and aesthetic needs. Understanding the complexities and requirements unique to each application allows professionals to optimize these systems for durability, efficiency, and visual integration. As an industry veteran committed to optimizing functionality and aesthetics in drainage solutions, my approach underscores the value of meticulous material selection and innovative design to leverage trench drain grates as not just infrastructural necessities, but as strategic enhancements to any project.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024