- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 08:15

Back to list

Steel Grating

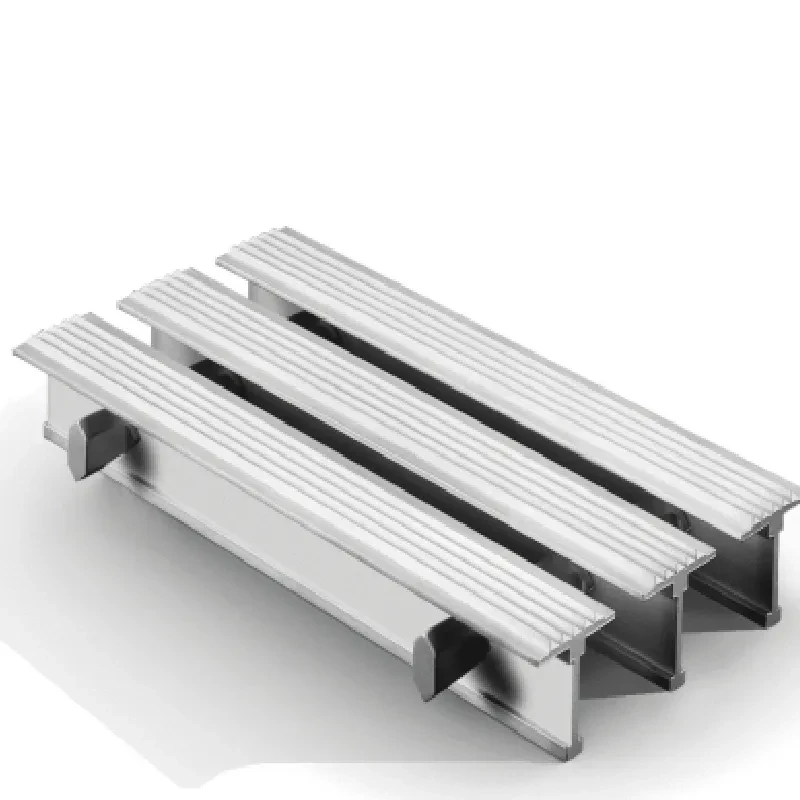

Swaged aluminum grating has emerged as an innovative solution for numerous industrial applications, combining lightweight properties with high strength and corrosion resistance. In comparison to traditional materials, swaged aluminum offers significant advantages in various environments, making it a preferred choice for many industries.

The expertise embedded within swaged aluminum grating production also speaks to its environmental benefits. Aluminum is one of the most recyclable materials on the planet. The energy saved from recycling aluminum as opposed to extracting it from ore significantly reduces environmental impacts, aligning the use of swaged aluminum grating with sustainable building practices. For companies and projects that prioritize sustainability, choosing aluminum grating can contribute positively towards achieving green building certifications and corporate sustainability goals. Trustworthiness in swaged aluminum grating is reinforced by its widespread acceptance and application in critical industries. Oil and gas platforms, chemical refineries, and aerospace facilities rely on this grating type not just for its corrosion resistance but for its non-sparking properties—a vital safety feature in environments where flammable substances may be present. This characteristic reduces the risk of fire hazards, further cementing its application as a reliable safety measure. Furthermore, swaged aluminum grating’s authoritative use is observed in its compliance with international safety standards. Companies manufacturing these gratings routinely engage in rigorous testing to ensure their products are calibrated according to international benchmarks. As such, they're frequently audited and validated by third-party certifying bodies, ensuring consistent quality across the board. These certifications provide additional peace of mind to safety and compliance officers, thereby enhancing the company’s credibility and authority in the industry space. Conclusively, swaged aluminum grating represents a synthesis of experience, expertise, authority, and trustworthiness. Its adoption across various sectors is a testament to its performance advantages and reliability. Industries looking to optimize for efficiency, while upholding high standards of safety and environmental responsibility, will find in swaged aluminum grating an unparalleled partner. The strategic choice to incorporate this material could thereby unlock cost-efficiencies and project longevity, as has been widely attested by industry professionals who trust its enduring capabilities.

The expertise embedded within swaged aluminum grating production also speaks to its environmental benefits. Aluminum is one of the most recyclable materials on the planet. The energy saved from recycling aluminum as opposed to extracting it from ore significantly reduces environmental impacts, aligning the use of swaged aluminum grating with sustainable building practices. For companies and projects that prioritize sustainability, choosing aluminum grating can contribute positively towards achieving green building certifications and corporate sustainability goals. Trustworthiness in swaged aluminum grating is reinforced by its widespread acceptance and application in critical industries. Oil and gas platforms, chemical refineries, and aerospace facilities rely on this grating type not just for its corrosion resistance but for its non-sparking properties—a vital safety feature in environments where flammable substances may be present. This characteristic reduces the risk of fire hazards, further cementing its application as a reliable safety measure. Furthermore, swaged aluminum grating’s authoritative use is observed in its compliance with international safety standards. Companies manufacturing these gratings routinely engage in rigorous testing to ensure their products are calibrated according to international benchmarks. As such, they're frequently audited and validated by third-party certifying bodies, ensuring consistent quality across the board. These certifications provide additional peace of mind to safety and compliance officers, thereby enhancing the company’s credibility and authority in the industry space. Conclusively, swaged aluminum grating represents a synthesis of experience, expertise, authority, and trustworthiness. Its adoption across various sectors is a testament to its performance advantages and reliability. Industries looking to optimize for efficiency, while upholding high standards of safety and environmental responsibility, will find in swaged aluminum grating an unparalleled partner. The strategic choice to incorporate this material could thereby unlock cost-efficiencies and project longevity, as has been widely attested by industry professionals who trust its enduring capabilities.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024