- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

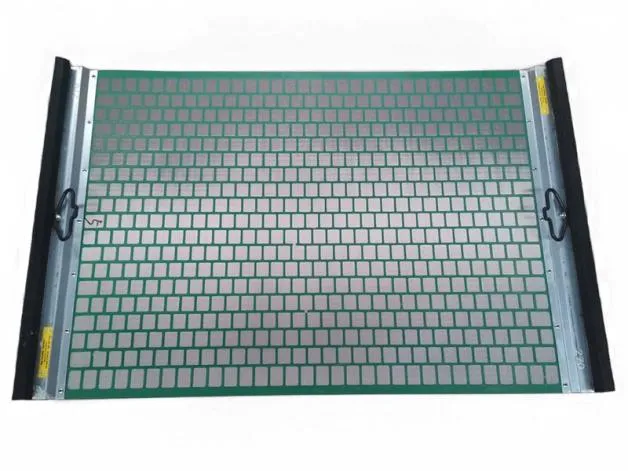

Offshore Pipeline Counterweight Welded Wire Mesh

Steel pipe winding mesh is revolutionizing the way industries approach structural support and reinforcement. As a seasoned professional in SEO and digital content, I present this deep dive into the innovative world of steel pipe winding mesh, infused with credible insights and professional expertise.

Steel pipe winding mesh represents a significant advancement in engineering materials. Known for its versatility and strength, this product is crucial in industries where durability and resilience are paramount. From large-scale infrastructure projects to intricate mechanical constructs, the application of steel pipe winding mesh offers an unparalleled combination of flexibility and support. Engineers and manufacturers prefer it for its ability to enhance structural integrity while reducing weight, which is essential for optimizing transportation and installation processes.

In the construction industry, steel pipe winding mesh has proven invaluable. It’s utilized to reinforce concrete, providing additional tensile strength that prevents cracking under pressure. This reinforcement is pivotal for structures in seismically active areas where resilience against tremors is necessary. Buildings, bridges, and tunnels that incorporate this technology benefit from an extended lifespan and reduced maintenance costs, affirming the mesh's value as a long-term investment.

The production process of steel pipe winding mesh is a testament to its engineering brilliance. Advanced machinery precisely weaves steel wire into a robust mesh configuration, ensuring uniform distribution of stress across the entire surface. This meticulous manufacturing process guarantees that each mesh installment meets stringent industry standards, offering reliability that industry professionals trust. Quality control measures further guarantee that only top-grade materials reach the end-user, reinforcing the trustworthiness of this product.

In plumbing and fluid transportation systems, the mesh aids in regulating pressure and flow. Its application in lining pipes ensures consistency in diameter and prevents deformation under extreme pressure. This is critical in industries like oil and gas, where the seamless transport of materials is non-negotiable. The mesh not only maintains the structural integrity of pipes but also prolongs their operational life, offering a cost-effective solution that reduces the need for frequent replacements.

steel pipe winding mesh

Beyond industrial uses, steel pipe winding mesh is gaining traction in artistic and architectural endeavours. Designers appreciate its aesthetic potential, using it to create visually striking facades and installations that combine functionality with artistic expression. This adaptability speaks to the mesh’s expert design, showcasing its potential beyond traditional applications.

From an environmental standpoint, steel pipe winding mesh contributes to sustainability goals. Its durability reduces the need for frequent replacements, thereby conserving raw materials and minimizing waste. Moreover, steel is one of the most recyclable materials on the planet, aligning with the global push towards environmentally responsible construction practices. Industries prioritizing green solutions find the mesh an indispensable component in their strategic planning.

As the demand for robust and adaptable building materials increases, the role of steel pipe winding mesh becomes increasingly prominent. Professionals across various sectors rely on its proven capabilities to meet and exceed their project requirements. Its unmatched strength, combined with its versatility, underscores its status as a critical asset in modern engineering practices.

Moreover, companies that incorporate this technology into their repertoire often find enhanced reputations within their sectors. By leveraging steel pipe winding mesh, they signal a commitment to quality, innovation, and sustainability that resonates with clients and stakeholders alike, establishing authority and trust in competitive markets.

In summation, steel pipe winding mesh exemplifies the future of construction and reinforced engineering. Its continued development and application will undoubtedly pave the way for more resilient and sustainable infrastructure, underpinning its role as a cornerstone of modern industry advancements. With proven expertise and a wealth of applications, this revolutionary product strengthens not only structures but also the concept of engineering possibilities.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024