- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 23, 2025 01:39

Back to list

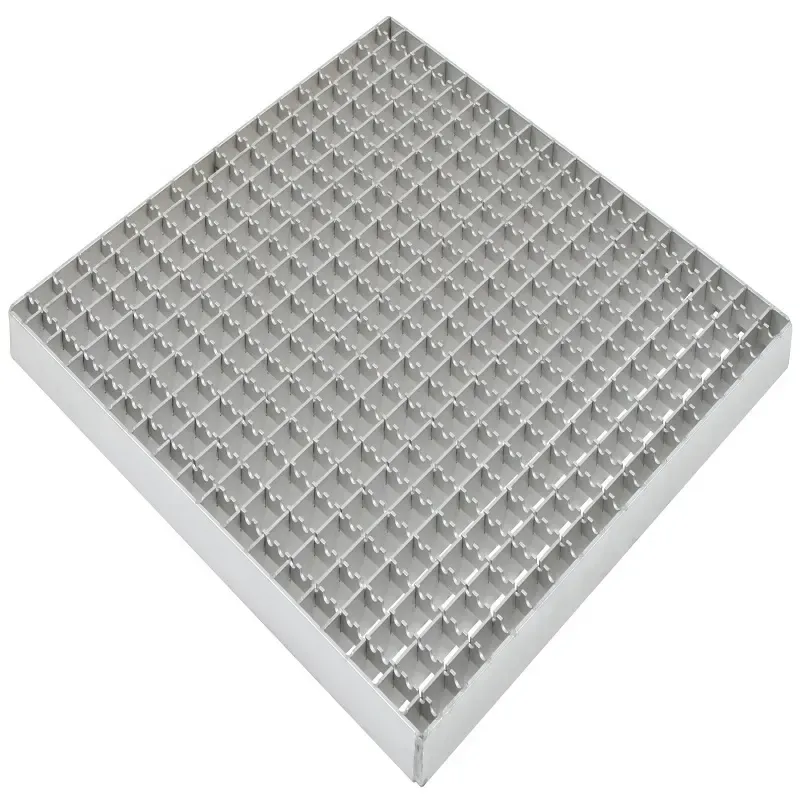

steel mesh floor grating

Steel mesh floor grating, an often overlooked yet integral component in construction and industrial sectors, offers a robust solution for flooring needs that require durability, safety, and functionality. This article delves into the nuances of steel mesh floor grating, providing insights into its various applications, benefits, and what to look for when selecting the right type for your project.

The type of load the grating will bear is crucial in determining the appropriate bar size and spacing. It is vital to calculate the expected load to avoid under-specifying, which can compromise safety and functionality. Consulting with a structural engineer or a grating specialist can provide valuable guidance in this aspect, ensuring that all load-bearing requirements are adequately met. Steel mesh floor grating's versatility is further enhanced by its aesthetic options. While functionality is paramount, appearance can also play a significant role in environments that require a specific visual appeal. Options for powder coating in various colors can help match the grating with the overall decor or safety color coding, enhancing both aesthetics and functionality. Finally, sourcing steel mesh floor grating from reputable manufacturers or suppliers is essential for ensuring quality and reliability. Look for manufacturers that adhere to industry standards and have a track record of excellence. Customer reviews and case studies of past projects can provide insight into the manufacturer's expertise and the quality of their products. As technology and manufacturing continue to advance, steel mesh floor grating is expected to become even more sophisticated, with enhancements in material composition and production techniques leading to greater performance capabilities. Staying informed about these advancements will help industry professionals select the most effective solutions to meet evolving needs. In conclusion, steel mesh floor grating is more than just a flooring solution; it is an investment in safety, longevity, and efficiency. Understanding the specific requirements of your environment and choosing the appropriate type of grating can significantly impact operational success and safety in various industrial applications.

The type of load the grating will bear is crucial in determining the appropriate bar size and spacing. It is vital to calculate the expected load to avoid under-specifying, which can compromise safety and functionality. Consulting with a structural engineer or a grating specialist can provide valuable guidance in this aspect, ensuring that all load-bearing requirements are adequately met. Steel mesh floor grating's versatility is further enhanced by its aesthetic options. While functionality is paramount, appearance can also play a significant role in environments that require a specific visual appeal. Options for powder coating in various colors can help match the grating with the overall decor or safety color coding, enhancing both aesthetics and functionality. Finally, sourcing steel mesh floor grating from reputable manufacturers or suppliers is essential for ensuring quality and reliability. Look for manufacturers that adhere to industry standards and have a track record of excellence. Customer reviews and case studies of past projects can provide insight into the manufacturer's expertise and the quality of their products. As technology and manufacturing continue to advance, steel mesh floor grating is expected to become even more sophisticated, with enhancements in material composition and production techniques leading to greater performance capabilities. Staying informed about these advancements will help industry professionals select the most effective solutions to meet evolving needs. In conclusion, steel mesh floor grating is more than just a flooring solution; it is an investment in safety, longevity, and efficiency. Understanding the specific requirements of your environment and choosing the appropriate type of grating can significantly impact operational success and safety in various industrial applications.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024