- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 20, 2025 01:12

Back to list

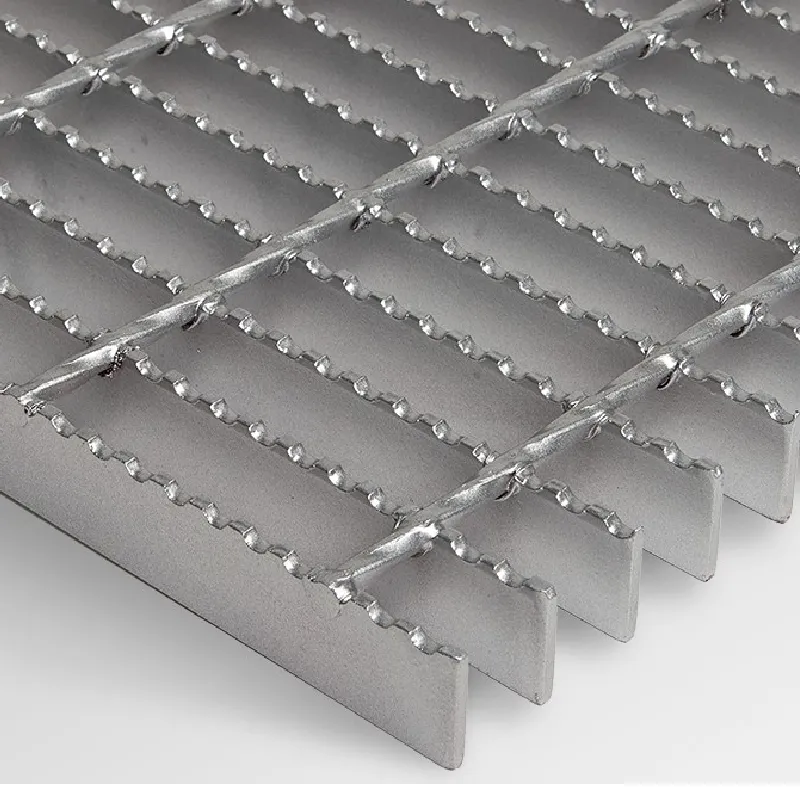

steel grid floor

Steel grid floors have long established their reputation as a key element in industrial and commercial environments. As an integral floor solution, they offer unparalleled strength, versatility, and safety. These floors are crafted by joining steel bars together to form a grid; the remarkable design provides excellent load distribution, making them ideal for a variety of applications from warehouses to catwalks, and even pedestrian bridges.

The authoritativeness of steel grid floors extends beyond their physical properties to include compliance with industry standards and safety regulations. Most steel grid floors adhere to rigorous quality standards, ensuring they meet or exceed load-bearing capacities mandated by occupational safety bodies. This compliance not only underscores the credibility of steel grid flooring but also enhances trust among stakeholders, knowing that their flooring solution is reliable and certified for use under extreme conditions. Trustworthiness in steel grid flooring is further enhanced by manufacturers’ warranties and a proven track record of performance across diverse industries. Many customers and industry experts cite the minimal maintenance requirements and the resilience of steel grid floors as significant benefits, contributing to their long-standing use in infrastructure projects. Regular inspections and preventive maintenance are usually sufficient to maintain their structural integrity, further establishing trust with end-users who rely on the floor’s consistent performance. In conclusion, steel grid floors represent a synthesis of engineering expertise and practical performance. Their adaptability and durability are well-documented, reflecting their long-standing utility across industrial applications. A combination of professional installation, authoritative compliance with safety standards, and the inherent trustworthiness of steel grid materials ensures that this flooring solution remains an invaluable asset. Whether dealing with complex environmental conditions or looking for a long-lasting industrial flooring option, steel grid floors provide a sound investment in safety and efficiency. With the growing need for sustainable and reliable infrastructure, steel grid floors continue to stand out as a premier choice for modern industrial applications.

The authoritativeness of steel grid floors extends beyond their physical properties to include compliance with industry standards and safety regulations. Most steel grid floors adhere to rigorous quality standards, ensuring they meet or exceed load-bearing capacities mandated by occupational safety bodies. This compliance not only underscores the credibility of steel grid flooring but also enhances trust among stakeholders, knowing that their flooring solution is reliable and certified for use under extreme conditions. Trustworthiness in steel grid flooring is further enhanced by manufacturers’ warranties and a proven track record of performance across diverse industries. Many customers and industry experts cite the minimal maintenance requirements and the resilience of steel grid floors as significant benefits, contributing to their long-standing use in infrastructure projects. Regular inspections and preventive maintenance are usually sufficient to maintain their structural integrity, further establishing trust with end-users who rely on the floor’s consistent performance. In conclusion, steel grid floors represent a synthesis of engineering expertise and practical performance. Their adaptability and durability are well-documented, reflecting their long-standing utility across industrial applications. A combination of professional installation, authoritative compliance with safety standards, and the inherent trustworthiness of steel grid materials ensures that this flooring solution remains an invaluable asset. Whether dealing with complex environmental conditions or looking for a long-lasting industrial flooring option, steel grid floors provide a sound investment in safety and efficiency. With the growing need for sustainable and reliable infrastructure, steel grid floors continue to stand out as a premier choice for modern industrial applications.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024