- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

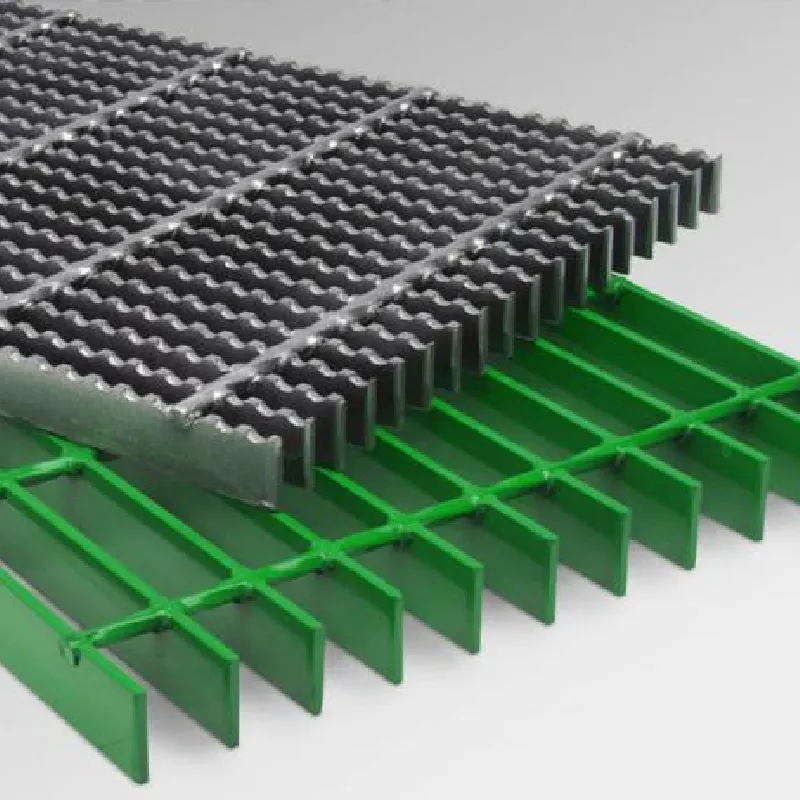

steel grating thickness

Understanding Steel Grating Thickness Importance and Applications

Steel grating is a versatile and widely used material in various industrial, commercial, and architectural applications. Its design features a grid-like structure, providing numerous benefits, such as strength, durability, and safety. One critical aspect of steel grating that often requires careful consideration is its thickness. This article will explore the importance of steel grating thickness, factors influencing its selection, and typical applications.

Importance of Steel Grating Thickness

The thickness of steel grating significantly impacts its performance and suitability for specific applications. Thicker grating tends to provide greater load-bearing capacity, making it ideal for heavy-duty environments, such as industrial settings, transportation infrastructure, and maintenance platforms. Conversely, thinner grating is often sufficient for lighter applications, such as walkways or decorative features.

Moreover, the thickness of the grating affects its overall weight and installation requirements. Thicker materials can lead to more substantial structural elements, which may require additional support and reinforcement. Therefore, understanding the appropriate thickness for a given use case is paramount for ensuring safety and efficiency.

Factors Influencing Steel Grating Thickness Selection

1. Load Requirements The primary factor in determining steel grating thickness is the anticipated load it will bear. Applications subjected to heavy machinery or substantial foot traffic necessitate thicker grating to withstand the increased stress without deforming or failing.

2. Span Length The distance between supports also influences the grating thickness. Longer spans typically require thicker grating to maintain structural integrity while preventing deflection and ensuring safety.

3. Material Properties The type of steel used can affect the necessary thickness. Some steel alloys exhibit higher strength, allowing for thinner grating in certain applications without compromising performance.

steel grating thickness

4. Environmental Conditions Grating exposed to harsh environments, such as corrosive chemicals or extreme temperatures, may require additional thickness or protective coatings to ensure longevity and performance.

5. Safety Standards Various industries are governed by safety regulations that dictate the minimum specifications for materials used in construction. Compliance with these standards is critical, and choosing the right thickness of steel grating ensures adherence to safety protocols.

Applications of Steel Grating Based on Thickness

Steel grating thickness plays a vital role in various applications.

- Industrial Flooring In heavy-duty industries, such as manufacturing and logistics, thicker steel grating is often used to support heavy machinery and equipment, ensuring worker safety and operational efficiency. - Walkways and Platforms For pedestrian walkways, medium thickness grating can provide sufficient strength while remaining lightweight enough for easy installation.

- Drainage Covers Thinner grating is commonly used in drainage applications, where minimal obstruction is required while still allowing for adequate water flow.

- Architectural Features In architectural applications, aesthetics may drive the choice of thickness, with thinner profiles often utilized for visual appeal while maintaining functionality.

In conclusion, the thickness of steel grating is a crucial factor that affects its load-bearing capacity, installation requirements, and overall safety. By considering the specific needs of each application, engineers and architects can make informed decisions that ensure the performance and longevity of steel grating in various environments.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024