- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 13:26

Back to list

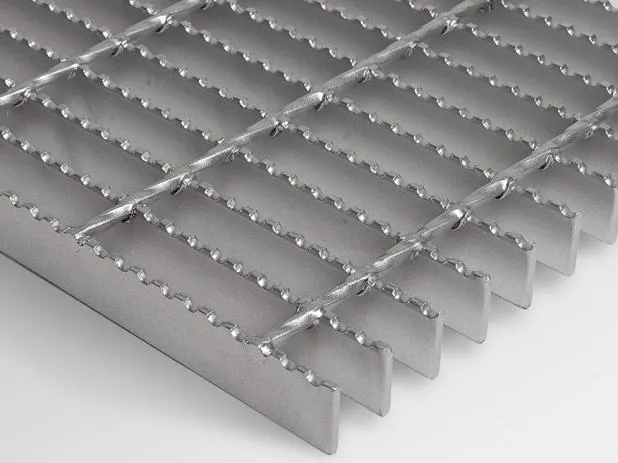

steel grating standard sizes

Steel grating, a versatile construction material, is often integral in various industrial and commercial applications. Its utility spans across platforms, walkways, and drainage covers, providing excellent strength and durability. Understanding the standard sizes of steel grating is crucial for ensuring optimal application, safety, and efficiency in any project, whether it's a large-scale industrial installation or a smaller architectural endeavor.

In terms of expertise, not all steel gratings are created equal. Adherence to global standards, such as ANSI/NAAMM (MBG 531) in North America and BS 4592 in the UK, guarantees the gratings' robustness and reliability. These standards are set based on comprehensive research and testing to confirm that steel gratings can withstand specific weights, climates, and conditions over long periods. Familiarity with these standards is a mark of a knowledgeable and professional producer, and purchasing products that adhere to these criteria ensures compliance with legal and safety guidelines. Authoritativeness in a producer doesn't stop at manufacturing standards. It extends to their track record, quality certification, and client testimonials. Enterprises with a longstanding presence and positive feedback from a global clientele typically have the authoritative know-how needed to deliver optimal, standard-compliant steel grating solutions. A trustworthy supplier provides not only high-quality products but also detailed installation instructions and support, minimizing risks and ensuring seamless integration into any construction framework. Furthermore, Trustworthiness is built through transparent pricing, quality guarantees, and comprehensive after-sales service. With steel grating being a vital component in many critical infrastructure projects, build quality can't be compromised. Suppliers who prominently display specifications, conduct rigorous quality control, and offer robust warranties gain the trust of their clients, fostering long-term relationships. Investing in the right steel grating standard size — informed by a blend of experience, expertise, authoritativeness, and trustworthiness — is indispensable in ensuring structural integrity and safety. Leveraging these four pillars provides both peace of mind and the assurance that any project, irrespective of scale, will stand the test of time and use. Balancing these factors effectively leads to not just meeting functional requirements but also potentially enhancing the overall aesthetic and value of a project.

In terms of expertise, not all steel gratings are created equal. Adherence to global standards, such as ANSI/NAAMM (MBG 531) in North America and BS 4592 in the UK, guarantees the gratings' robustness and reliability. These standards are set based on comprehensive research and testing to confirm that steel gratings can withstand specific weights, climates, and conditions over long periods. Familiarity with these standards is a mark of a knowledgeable and professional producer, and purchasing products that adhere to these criteria ensures compliance with legal and safety guidelines. Authoritativeness in a producer doesn't stop at manufacturing standards. It extends to their track record, quality certification, and client testimonials. Enterprises with a longstanding presence and positive feedback from a global clientele typically have the authoritative know-how needed to deliver optimal, standard-compliant steel grating solutions. A trustworthy supplier provides not only high-quality products but also detailed installation instructions and support, minimizing risks and ensuring seamless integration into any construction framework. Furthermore, Trustworthiness is built through transparent pricing, quality guarantees, and comprehensive after-sales service. With steel grating being a vital component in many critical infrastructure projects, build quality can't be compromised. Suppliers who prominently display specifications, conduct rigorous quality control, and offer robust warranties gain the trust of their clients, fostering long-term relationships. Investing in the right steel grating standard size — informed by a blend of experience, expertise, authoritativeness, and trustworthiness — is indispensable in ensuring structural integrity and safety. Leveraging these four pillars provides both peace of mind and the assurance that any project, irrespective of scale, will stand the test of time and use. Balancing these factors effectively leads to not just meeting functional requirements but also potentially enhancing the overall aesthetic and value of a project.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024