- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

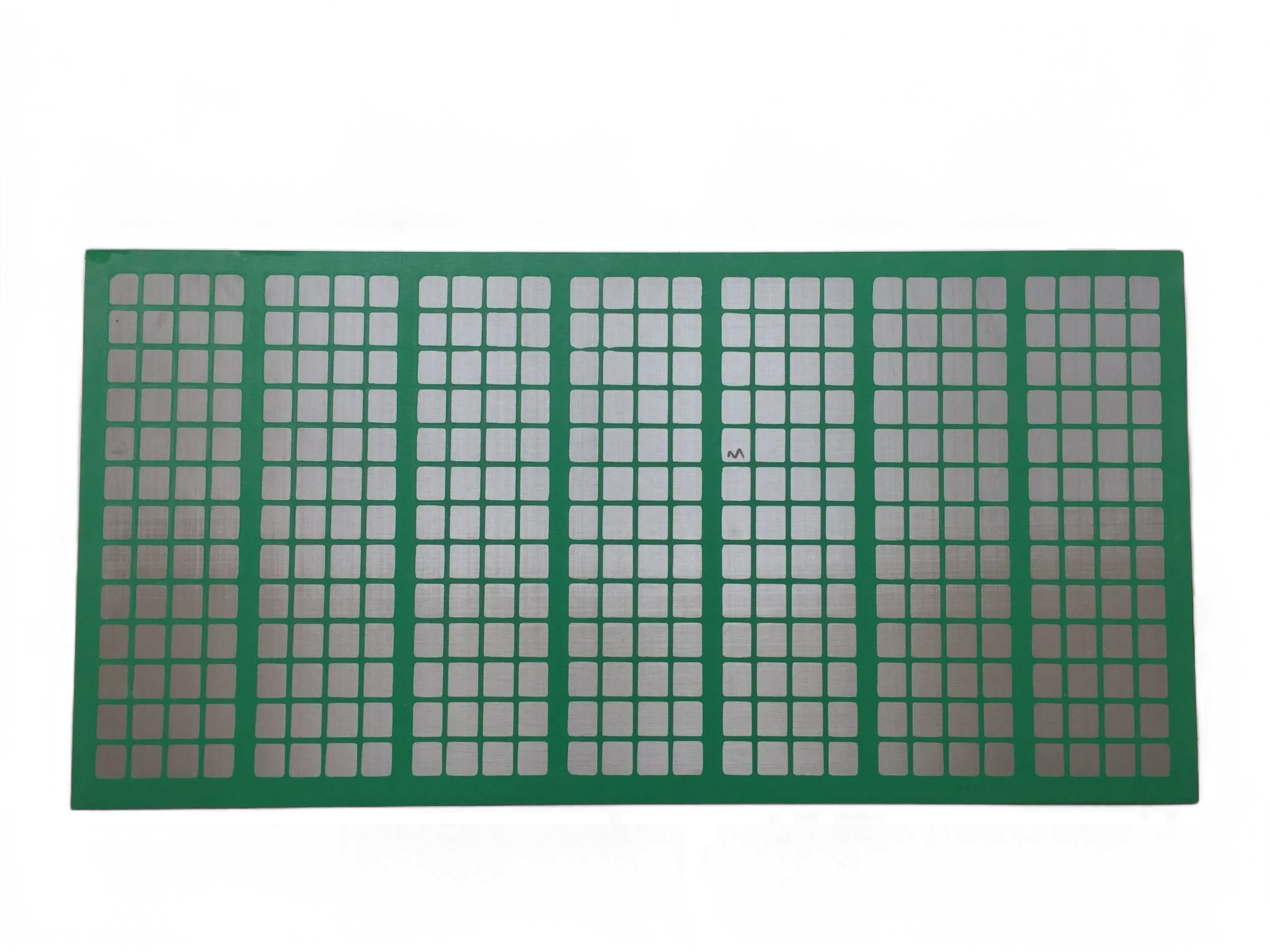

steel grating specifications

Steel grating is an essential material widely used in various industries due to its unique combination of strength, durability, and versatility. It consists of a series of parallel bars or slats, welded together to form a grid-like structure that can support heavy loads while allowing for drainage and ventilation. Understanding steel grating specifications is crucial for selecting the right type for specific applications.

First and foremost, the material composition of steel grating is a vital aspect of its specification. Most commonly, it is made from carbon steel or stainless steel, with each type serving different environmental conditions. Carbon steel is typically used in non-corrosive environments, while stainless steel, known for its high corrosion resistance, is preferred in more demanding applications, such as chemical processing and marine environments.

Another critical specification is the bar spacing and thickness. The spacing between the bars can influence the load-bearing capacity and the weight of the grating. Standard spacing typically varies from 1 inch to 2 inches, but custom configurations are available to meet specific needs. Additionally, the thickness of the bars can range from 1/8 inch to 1/2 inch or more, impacting both strength and weight.

steel grating specifications

Load capacity ratings are also an essential component of steel grating specifications. The load capacity is typically expressed in terms of the amount of weight the grating can support over a given span. This is determined by the material properties, bar dimensions, and spacing. Manufacturers often provide load tables to help engineers and builders select the appropriate grating type based on their project's requirements.

Furthermore, surface treatments greatly affect the performance of steel grating. Common treatments include galvanization, which provides a protective zinc coating to prevent rust and corrosion, and powder coating, which adds aesthetic appeal as well as additional protection.

In summary, understanding steel grating specifications is essential for selecting the appropriate type for specific applications. Key considerations include material composition, bar spacing and thickness, load capacity ratings, and surface treatments. When chosen correctly, steel grating provides a reliable and efficient solution for a wide range of industrial and commercial applications, enhancing safety and functionality.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024