- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

steel grating span tables

Understanding Steel Grating Span Tables A Comprehensive Guide

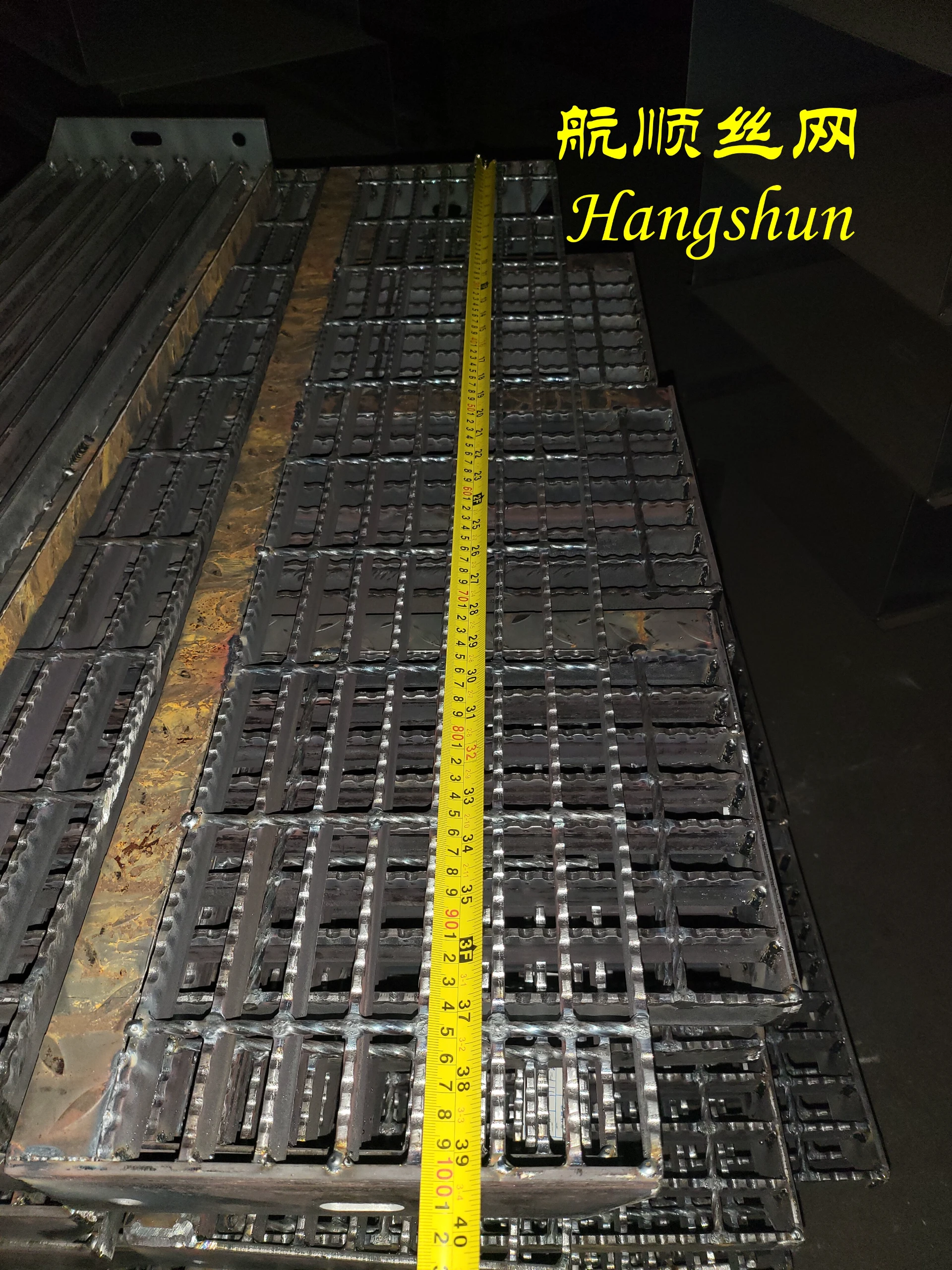

Steel grating is a popular flooring solution known for its strength, durability, and versatility. Commonly used in industrial applications, pedestrian walkways, and various construction projects, steel grating provides a reliable platform that can withstand heavy loads and adverse environmental conditions. One critical aspect of utilizing steel grating efficiently is understanding its span tables. These tables are essential for determining the appropriate spacing between bearings, ensuring safety and functionality in construction.

What Are Span Tables?

Span tables for steel grating provide guidelines on the load-bearing capacity of different types of grating at specified spans. They are crucial for engineers, architects, and construction managers to select the right type of grating for their projects, taking into account the loads that the grating will need to support, as well as design factors like deflection limits and safety requirements.

Key Factors Affecting Span Tables

1. Material Properties The type of steel grating material (e.g., plain, serrated, or galvanized) affects its load-bearing capacity. Serrated grating, for instance, provides better slip resistance, which can be a vital consideration in wet or oily environments.

2. Load Types Span tables differentiate between live loads (temporary loads such as foot traffic or equipment) and dead loads (permanent loads like the weight of the grating itself). Understanding the nature of the load helps in choosing the correct span.

3. Grating Thickness The thickness of the steel grating significantly impacts its strength and load-bearing capabilities. Thicker grating usually allows for longer spans between supports.

4. Support Configuration The arrangement of supports, whether they are parallel or perpendicular to the grating, greatly influences the span. The spacing can often be adjusted according to the specific application and load requirements.

5. Deflection Limits Most applications have specific deflection limits that must not be exceeded for safety and comfort. For walkways, the maximum allowable deflection might be around 1/4 inch, while heavier-duty applications might permit less deflection.

steel grating span tables

Utilizing Span Tables

To use span tables effectively, follow these steps

1. Identify the Application Determine the specific use of the steel grating—whether it will be exposed to heavy machinery, pedestrian foot traffic, or hazardous materials.

2. Calculate Load Requirements Assess both live and dead loads that the grating will support. This might require engineering input if heavy machinery is involved.

3. Select Grating Type Based on the required load capacity, choose an appropriate type of grating (e.g., light duty or heavy duty). The finish and tread design also play a role in safety and usability.

4. Refer to Span Tables Once you have your load requirements and grating type, consult the span tables. Locate the column corresponding to your chosen grating type and look for the corresponding load values and spans.

5. Check Deflection Standards Ensure that the selected span does not exceed the maximum deflection allowed for your specific application.

6. Apply Safety Factors Incorporating safety factors into your final design is crucial. Always consider potential overload scenarios and ensure that the design allows for unexpected loads.

Conclusion

Understanding and utilizing steel grating span tables is essential for anyone involved in construction and engineering projects. These tables provide scientific and empirical data necessary for ensuring that the grating will function safely and effectively over its intended lifespan. Proper application of span tables not only enhances the safety of structures but also contributes to cost-effective materials management by preventing over-specification or premature failure. By following the guidelines outlined in span tables, professionals can confidently design and implement steel grating solutions tailored to their specific needs. Always consult with a structural engineer when in doubt, as they can provide expert insights tailored to the unique demands of each project.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024