- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Steel Grating Span Guidelines for Optimal Load Support and Safety Considerations

Understanding Steel Grating Span Tables A Comprehensive Guide

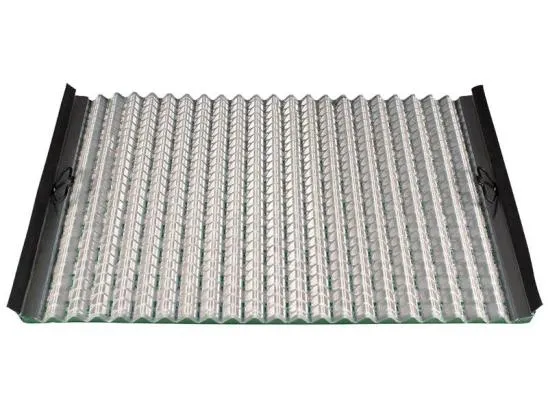

Steel grating is a vital component in various industrial applications, providing a durable and cost-effective solution for flooring, walkways, and platforms. One of the key considerations when selecting steel grating is the span— the distance between the support points. Span tables for steel grating offer crucial information that helps engineers and designers ensure the safety and functionality of their applications. In this article, we will explore the significance of these span tables, how to interpret them, and the factors affecting span selection.

What are Steel Grating Span Tables?

Steel grating span tables are structured guidelines that provide maximum allowable spans for different types of steel grating materials, sizes, and load classifications. These tables typically indicate how far the grating can safely extend between supports based on various loading conditions—whether static, dynamic, or impact loads. By referencing these tables, designers can make informed decisions about the type and configuration of grating necessary for their specific application.

The Importance of Correct Spanning

Correctly determining the span of steel grating is essential for several reasons

1. Safety Overextending the span beyond the recommended limits can lead to structural failures, including bending, breaking, or collapsing under load conditions. This not only poses a risk to personnel but can also damage equipment and impede operations.

2. Cost-Effectiveness Using properly specified spans can prevent unnecessary material costs. Selecting a grating with an inappropriate span may require additional support structures, increasing the overall project budget.

3. Compliance Many industries are regulated by strict standards concerning safety and structural integrity. Adhering to span tables can assist in meeting these compliance requirements.

How to Interpret Span Tables

Span tables are usually presented in a tabular format with rows and columns detailing the type of grating, span distances, load factors, and safety ratings. Here’s how to interpret the key components

- Grating Type Different types of grating, such as welded steel or press-locked grating, have varying strengths and clearances

. It is important to ensure that the type being referenced matches your application.steel grating span tables

- Span Length The table will indicate the maximum span permitted for various load configurations, usually specified in inches or millimeters.

- Load Classifications Load types are typically categorized based on standard load ratings, including pedestrian traffic, vehicular loads, or heavy equipment. Understanding the expected load on the grating will guide you in selecting the correct span.

- Safety Factors The span tables incorporate safety factors, often based on industry standards or recommendations. It’s crucial to factor in these safety considerations when making decisions.

Factors Influencing Span Selection

Several factors can influence the selection of the appropriate span from the steel grating span tables

1. Load Conditions The type and magnitude of loads that the grating will bear are paramount in determining the correct span.

2. Environmental Conditions Grating exposed to corrosive environments or extreme temperature variations may have different durability and span capabilities.

3. Material Specifications Variations in steel quality and grating manufacturing processes will affect performance under load.

4. Intended Use Applications such as industrial flooring, stair treads, or drainage covers may require different spans based on functional needs and safety considerations.

Conclusion

Selecting the correct span for steel grating is crucial for ensuring safety, compliance, and cost-effectiveness in various applications. By understanding and utilizing steel grating span tables, engineers and designers can make informed decisions that promote structural integrity and operational efficiency. Always consult relevant guidelines and engineering experts when dealing with specific projects to ensure optimal outcomes.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024