- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

steel grating sizes

Understanding Steel Grating Sizes

Steel grating is an essential component in various industrial and construction applications. It provides robust support and safety while allowing for drainage and ventilation. Understanding the different sizes of steel grating is critical for selecting the right type for your project needs.

Steel grating comes in a variety of sizes and configurations, which can be categorized based on the bar spacing, thickness, and load-bearing capabilities. The most common types include welded steel grating, press-locked grating, and swaged grating. Each type offers distinct advantages, depending on the material requirements and the environment in which they will be used.

Understanding Steel Grating Sizes

Thickness also plays a pivotal role in determining the strength and durability of steel grating. Common thicknesses range from 1/4 inch to 1 inch. Thicker grating can support more weight and withstand harsher conditions, making it preferable in high-traffic areas or heavy machinery settings.

steel grating sizes

When it comes to load-bearing capabilities, steel gratings are classified into various load ratings such as pedestrian, light duty, and heavy-duty. For instance, pedestrian load ratings are typically suitable for walkways and light foot traffic, while heavy-duty options are designed for use in warehouses or areas subject to heavy machinery. Understanding the load requirements of your project is crucial to choosing the appropriate size and type.

Another important aspect is the finish of the steel grating, which can impact its size and functionality. Common finishes include hot-dip galvanizing or powder coating that enhance corrosion resistance and provide aesthetic appeal. These finishes can slightly affect the dimensions of the grating but are essential for ensuring longevity, especially in outdoor or harsh environments.

Lastly, customization is a key benefit of steel grating. Many manufacturers offer bespoke sizes to meet specific project requirements. This flexibility allows for fitting into unique spaces or meeting specialized load needs while ensuring the integrity of the structure.

In summary, when selecting steel grating sizes for your project, consider bar spacing, thickness, load ratings, finishes, and customization options. By understanding these factors, you can make an informed decision that ensures both functionality and safety, crucial for any industrial or construction application. Through careful consideration of these parameters, you can harness the full advantages of steel grating in your projects.

-

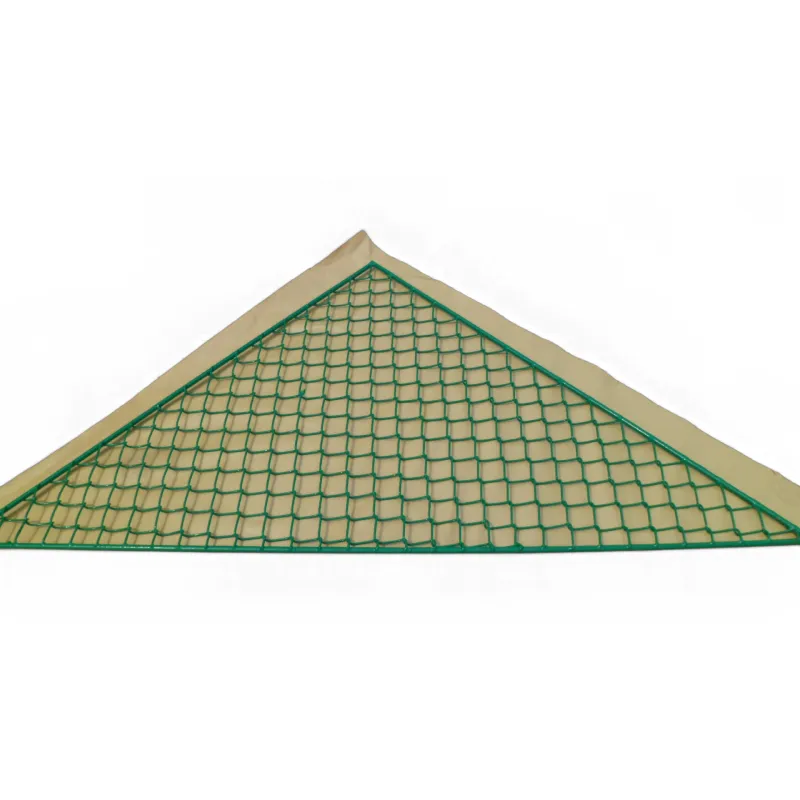

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024