- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

steel grating price

Understanding Steel Grating Prices Factors and Insights

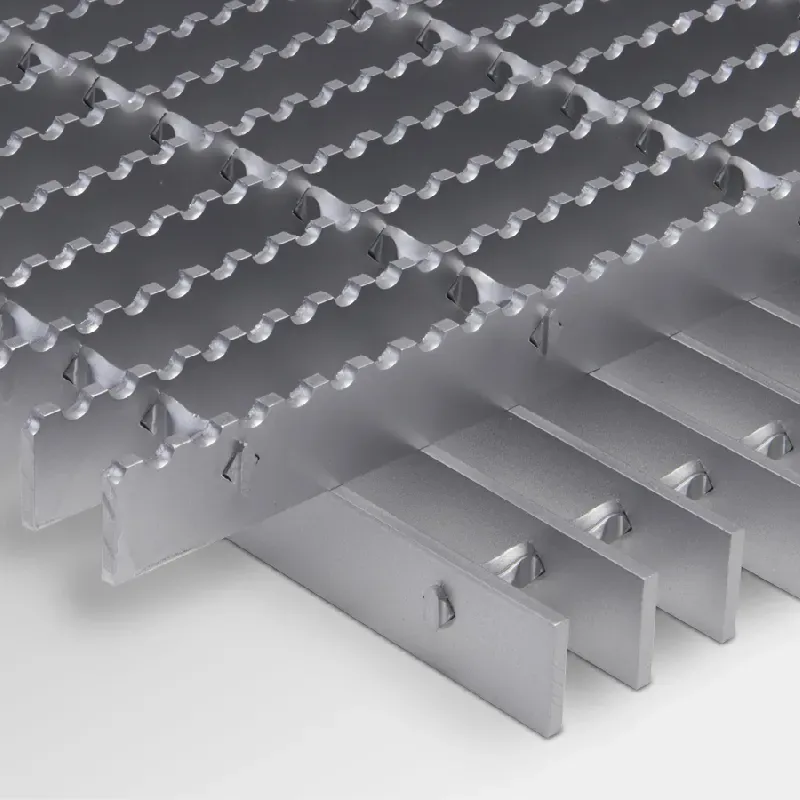

Steel grating is an essential material commonly used in a variety of industrial and commercial applications, including walkways, platforms, and drainage covers. The price of steel grating can vary significantly based on several key factors, which can impact both project budgets and procurement strategies.

One of the primary factors influencing steel grating prices is the type of steel used in its manufacture. Mild steel, stainless steel, and aluminum are among the most common materials for grating. Mild steel is often the most cost-effective option, offering good strength at a lower price point. However, stainless steel, known for its corrosion resistance and durability, tends to be more expensive. Thus, when selecting materials for a project, it’s crucial to balance cost with environmental factors and the specific demands of the application.

Another determinant of steel grating prices is the manufacturing process. Different methods, such as welding, press-locking, or forged production, can vary in cost. For instance, welded grating, while highly durable and suitable for heavy loads, may have a higher initial price due to the intensive manufacturing process. Press-locked grating, on the other hand, may be cheaper but could be less robust under certain conditions. Understanding the trade-offs associated with each method helps buyers make informed decisions while keeping costs within budget.

steel grating price

The dimensions and specifications of the steel grating also play a significant role in pricing. Custom sizes or specific load ratings can lead to additional costs, as these require specialized manufacturing processes or equipment. Generally, standard sizes and designs are more readily available and can be more affordable. Therefore, when possible, utilizing standard dimensions can save money without compromising quality.

Additionally, market factors can influence pricing trends. Fluctuations in raw material costs, such as the price of steel itself, can lead to changes in grating prices. Global events, tariffs, and supply chain disruptions can also have a ripple effect, thus impacting availability and cost. Buyers should stay informed about market conditions to better anticipate price changes and make strategic purchasing decisions.

Lastly, purchasing in bulk often results in significant savings. Many manufacturers and suppliers offer discounts for larger orders, making it economically advantageous for businesses requiring substantial amounts of steel grating.

In conclusion, understanding the factors that affect steel grating prices is vital for anyone involved in procurement or construction. By considering material types, manufacturing methods, specifications, market conditions, and bulk purchasing strategies, buyers can make more informed decisions that align with their financial and operational goals. Whether for industrial projects or commercial developments, being aware of these pricing dynamics ensures that one gets the best value for their investment in steel grating.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024