- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Cost Factors and Pricing Trends for Steel Grating in Today's Market

Understanding Steel Grating Prices Factors and Considerations

Steel grating is a widely used material in various industrial applications, including flooring, walkways, drainage covers, and more. Its popularity is attributed to its strength, durability, and ability to provide excellent drainage while maintaining high visibility. However, when it comes to purchasing steel grating, many buyers often wonder what factors influence the price of steel grating? In this article, we’ll explore the key elements that affect steel grating pricing and provide insights for potential buyers.

1. Material Composition

The primary factor affecting the price of steel grating is its material composition. Steel grating can be made from different types of steel, including carbon steel, stainless steel, and aluminum. The choice of material significantly impacts the cost, as stainless steel, for example, tends to be more expensive than carbon steel due to its corrosion resistance and durability in harsh environments. Moreover, the grade of the steel used can also influence pricing, with higher-grade materials typically commanding higher prices.

2. Grating Type

There are several types of steel grating available, such as welded steel grating, pressed steel grating, and molded grating. Each type has its own manufacturing processes and applications, which can affect the overall cost. For instance, welded steel grating, known for its robust structure and load-bearing capacity, may be priced higher than pressed steel grating, which is lighter and easier to manufacture but may not support as much weight.

3. Size and Load Capacity

The dimensions and load capacity required for the steel grating can also affect its price. Larger grating panels require more raw material, leading to increased costs. Additionally, grating designed to support heavier loads typically involves a more complex manufacturing process, further adding to the price. When selecting grating, it’s crucial to balance between the required specifications and budget, ensuring you choose a product that provides adequate performance without overspending.

steel grating price

The surface finish of the steel grating can impact its price as well. Common finishes include hot-dip galvanizing, powder coating, and untreated surfaces. Hot-dip galvanizing is a process where the grating is dipped in molten zinc, enhancing its corrosion resistance and longevity, but it also adds an extra layer to the cost. Powder coating provides an aesthetic appeal and additional protection; however, it can also be an additional expense. When choosing a finish, consider the environment in which the grating will be used, as this will help determine the necessary protection levels.

5. Manufacturing Process

The price of steel grating is also influenced by the manufacturing process used. Processes such as forging, welding, or pressing vary in complexity and resource requirements. For example, welded steel grating is often more labor-intensive and requires skilled workmanship, potentially resulting in higher prices compared to simpler manufacturing methods. Additionally, regional manufacturing capabilities and labor costs can affect pricing in different markets.

6. Market Demand and Supply

Like any commodity, the pricing of steel grating is subject to market demand and supply dynamics. Fluctuations in the price of raw materials, including steel, can have direct effects on production costs and, in turn, grating prices. Economic trends, seasonal demand, and construction activity can also influence pricing, making it essential for buyers to stay informed about market conditions.

7. Supplier and Quantities

The price per unit of steel grating can also vary depending on the supplier and order quantity. Bulk orders often attract discounts, so purchasing larger quantities may reduce per-unit costs. It’s advisable to compare prices from various suppliers and check for special promotions or bulk offers to ensure the best value for your investment.

Conclusion

Understanding the factors that influence steel grating prices is crucial for making informed purchasing decisions. By considering material composition, type, size, surface finish, manufacturing processes, and market dynamics, buyers can navigate the marketplace more effectively. Whether used in industrial applications, commercial installations, or residential projects, steel grating remains a valuable investment, and being informed can lead to smarter purchasing choices that fit both needs and budget.

-

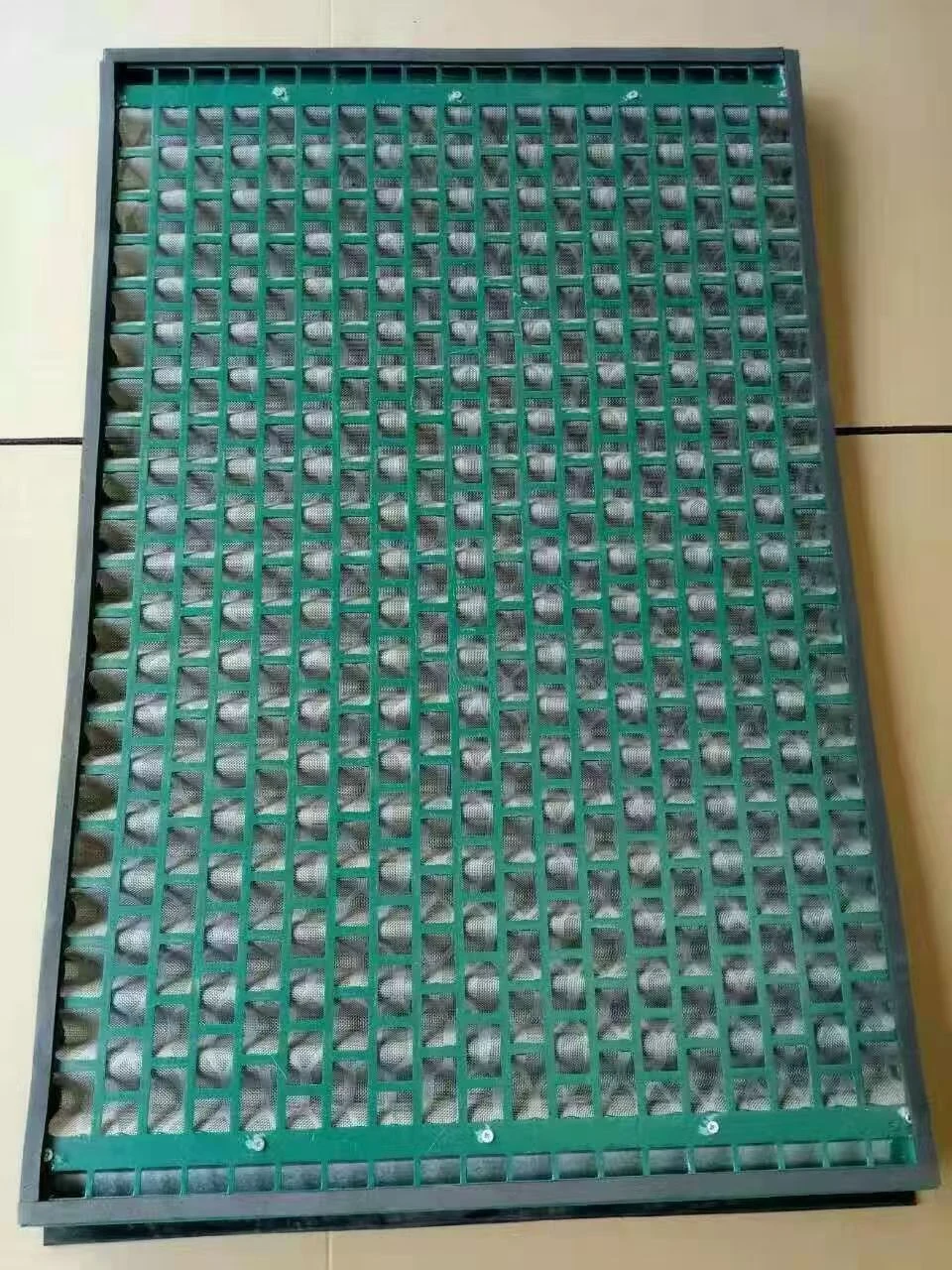

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024