- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 06, 2025 10:57

Back to list

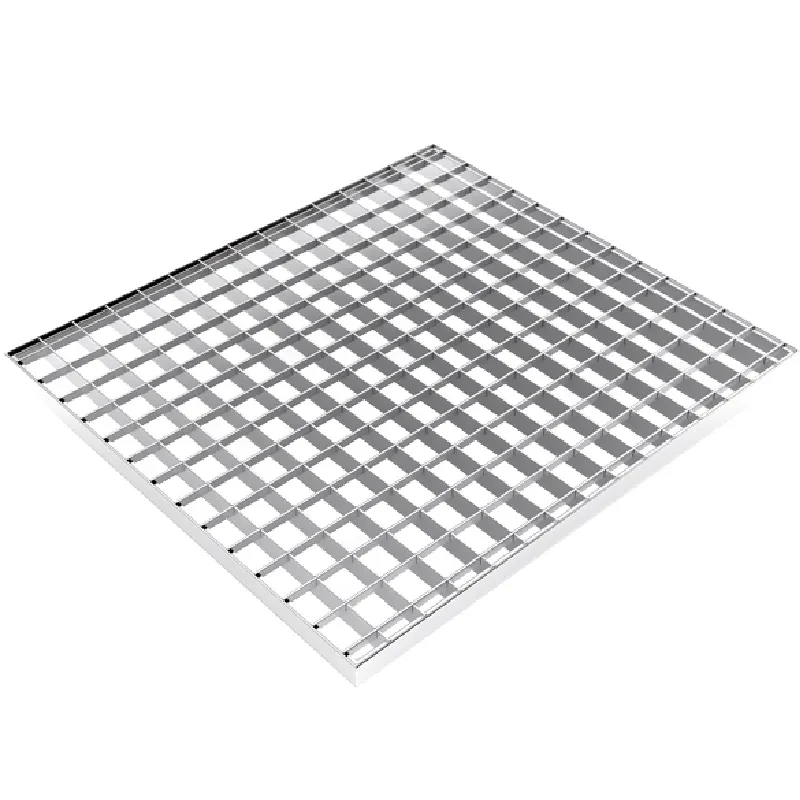

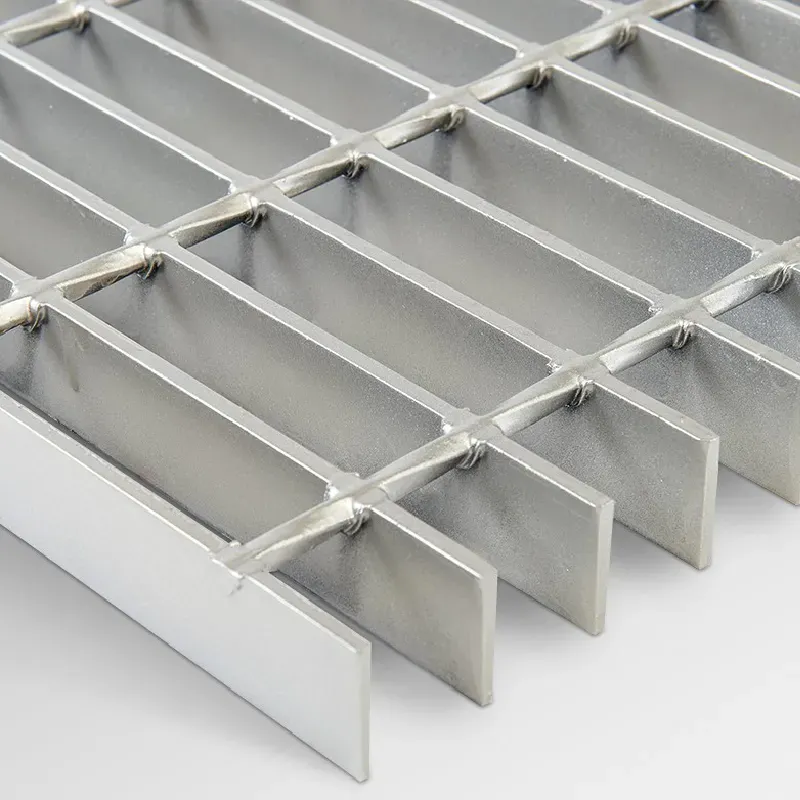

steel grating price

Steel grating has emerged as a crucial element in various industrial and commercial applications, owing to its strength, durability, and versatility. When navigating the complex landscape of steel grating pricing, it is essential to understand the factors that influence cost, which can enhance purchasing strategies and contribute to informed decision-making.

Import duties and shipping costs are another consideration for companies sourcing steel grating internationally. These additional expenses can significantly affect the total cost, making local suppliers more appealing in certain regions. Evaluating the full logistical costs against the base price of the grating itself is crucial for an accurate assessment of total project expenses. Leveraging industry expertise can greatly aid in understanding and predicting steel grating prices. Consulting with industry experts and staying updated with industry publications and reports can provide insights into upcoming trends and innovations that may affect future pricing. This proactive approach can lead to strategic purchasing that anticipates price increases or takes advantage of falling prices. Buyers should also consider the long-term value of their investment. While initial costs are crucial, the longevity and maintenance needs of the grating should be factored into the overall cost-benefit analysis. Materials with higher upfront costs might offer more extended service life and lower maintenance, thus providing better value over time. Trustworthiness in supplier relationships is paramount. Working with reputable suppliers who provide transparent pricing, detailed specifications, and solid warranties is necessary to ensure quality and fair pricing. This builds trust and confidence, ensuring that what is paid for is truly what is received. In conclusion, understanding steel grating prices involves a comprehensive look at material types, manufacturing processes, market conditions, and logistical considerations while ensuring a focus on long-term value and supplier credibility. This strategic approach can enhance the purchasing experience, yielding benefits of cost efficiency and value maximization. Through expertise and informed analysis, decision-makers can navigate the complexities of the steel grating market with assurance and authority.

Import duties and shipping costs are another consideration for companies sourcing steel grating internationally. These additional expenses can significantly affect the total cost, making local suppliers more appealing in certain regions. Evaluating the full logistical costs against the base price of the grating itself is crucial for an accurate assessment of total project expenses. Leveraging industry expertise can greatly aid in understanding and predicting steel grating prices. Consulting with industry experts and staying updated with industry publications and reports can provide insights into upcoming trends and innovations that may affect future pricing. This proactive approach can lead to strategic purchasing that anticipates price increases or takes advantage of falling prices. Buyers should also consider the long-term value of their investment. While initial costs are crucial, the longevity and maintenance needs of the grating should be factored into the overall cost-benefit analysis. Materials with higher upfront costs might offer more extended service life and lower maintenance, thus providing better value over time. Trustworthiness in supplier relationships is paramount. Working with reputable suppliers who provide transparent pricing, detailed specifications, and solid warranties is necessary to ensure quality and fair pricing. This builds trust and confidence, ensuring that what is paid for is truly what is received. In conclusion, understanding steel grating prices involves a comprehensive look at material types, manufacturing processes, market conditions, and logistical considerations while ensuring a focus on long-term value and supplier credibility. This strategic approach can enhance the purchasing experience, yielding benefits of cost efficiency and value maximization. Through expertise and informed analysis, decision-makers can navigate the complexities of the steel grating market with assurance and authority.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024