- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

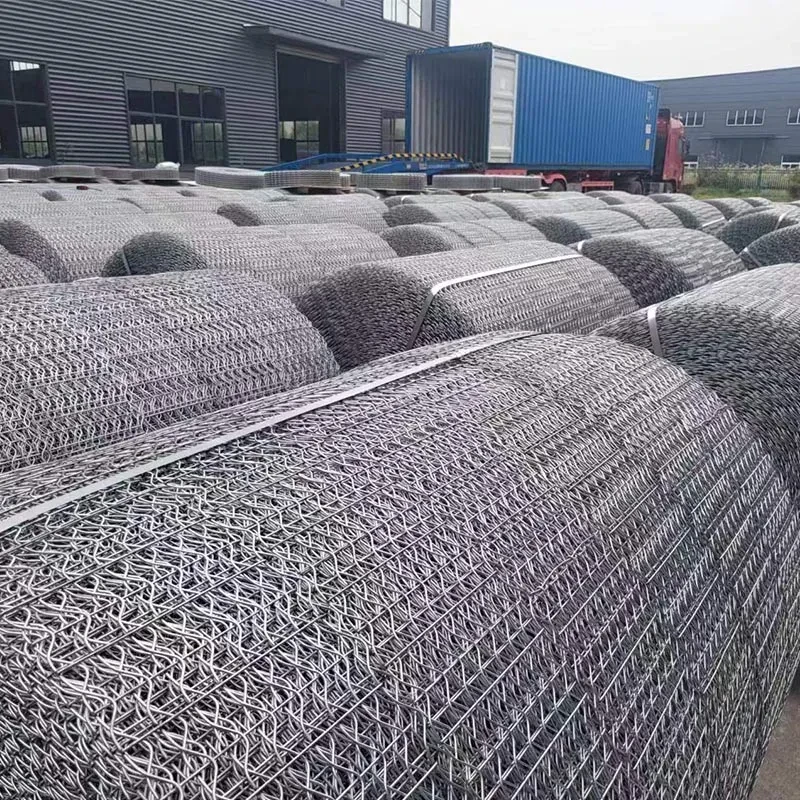

steel grating price

Understanding Steel Grating Prices Factors and Insights

Steel grating is widely used in various industries for its strength, durability, and versatility. Common applications include walkways, platforms, drainage covers, and fencing. The price of steel grating can vary significantly based on several factors, which we will explore in detail. Understanding these factors can help buyers make informed decisions when purchasing steel grating for their projects.

1. Material Type

The primary material used in steel grating is carbon steel, but other materials such as stainless steel and aluminum can also be used. Carbon steel is often the most economical choice, while stainless steel grating tends to be more expensive due to its corrosion resistance, making it suitable for environments exposed to moisture and chemicals. The choice of material directly influences the price; thus, assessing the environmental conditions and longevity requirements of your project is essential when determining the type of steel grating needed.

2. Manufacturing Process

Steel grating production involves various processes, including welding, forging, and machining. The method employed can impact pricing. For instance, welded steel grating is typically more affordable than pressure-locked grating, which requires more sophisticated manufacturing techniques and labor. Furthermore, custom fabrication (tailored sizes and shapes) generally incurs additional costs. When considering your project's specifications, it’s essential to keep in mind the balance between the manufacturing process and your budget.

3. Load Capacity

Steel grating is designed to support different loads depending on its thickness, spacing, and overall design. Gratings with higher load-bearing capacities are often made from thicker steel and may feature more bars per square foot. As the load capacity increases, so does the price. Prospective buyers need to assess the load requirements of their application to ensure that they select the appropriate type of grating without overspending on unnecessary capacity.

steel grating price

Steel grating can undergo various surface treatments to enhance its performance and longevity. Options include galvanization, powder coating, and painting. Galvanization, in particular, provides significant corrosion resistance and is commonly used for steel grating intended for outdoor applications. This treatment adds to the overall cost but can lead to cost savings in maintenance and replacement in the long run. Buyers should evaluate the trade-off between initial expenses and long-term durability when considering surface treatments.

5. Size and Dimensions

The dimensions of the steel grating—such as length, width, and thickness—also play a crucial role in determining the price. Larger pieces may incur higher shipping costs, while custom sizes may lead to additional fabrication fees. Standard sizes tend to be more cost-effective due to mass production. Buyers should size their needs correctly, taking care to consider how dimensions will impact both functionality and budget.

6. Market Demand and Economic Factors

Like all commodities, the price of steel grating is influenced by market demand and broader economic conditions. Fluctuations in steel prices due to changes in raw material availability can directly impact the cost of steel grating. Additionally, geopolitical events and tariffs can affect pricing. Buyers should consider these market conditions when planning their procurement timelines, as timing can significantly impact costs.

7. Supplier and Location

The choice of supplier can profoundly affect steel grating prices. Established manufacturers may have economies of scale that allow them to offer competitive pricing, while smaller suppliers may charge more due to lower production volumes. Moreover, local suppliers may save on shipping costs, making prices more attractive compared to distant distributors. It's advisable to compare quotes from multiple suppliers and factor in shipping costs when evaluating offers.

Conclusion

Steel grating prices are influenced by a myriad of factors including material type, manufacturing process, load capacity, surface treatment, size, market demand, and supplier location. Understanding these components will empower buyers to navigate the purchasing process more effectively, ensuring they invest wisely in steel grating that meets their project requirements. Whether you’re looking for an economical option or something that promises enhanced performance, knowledge of these aspects will guide you towards making the best choice for your needs. With careful consideration of these factors, you can achieve both functionality and value in your steel grating projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024