- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

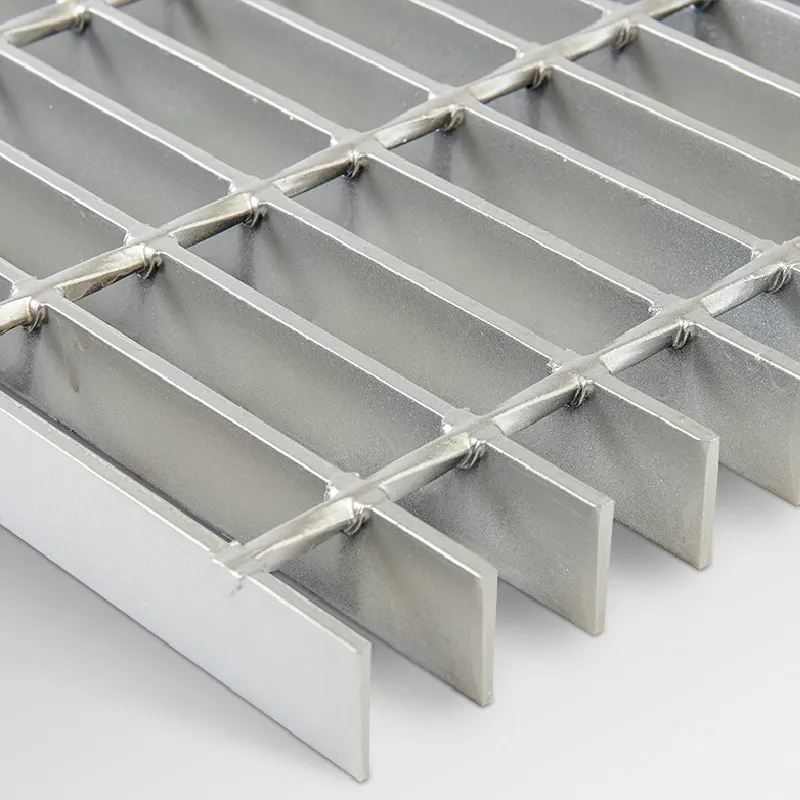

Durable Steel Grating Panels for Industrial and Commercial Applications

Understanding Steel Grating Plates An Essential Component in Modern Engineering

Steel grating plates have become an integral component in various construction and industrial applications due to their strength, durability, and versatility. These flat structures, composed of interconnected steel bars or rods, offer numerous benefits that make them a preferred choice for engineers and architects alike.

What Are Steel Grating Plates?

Steel grating plates are made from various types of steel and are typically manufactured in a mesh pattern. This mesh is created by welding or fabricating steel bars together in a grid-like structure. The spacing and design can vary based on the intended use, with options ranging from heavy-duty grating for industrial applications to lighter options for pedestrian use. They come in different thicknesses and sizes, accommodating diverse needs and specifications.

Applications of Steel Grating Plates

The applications of steel grating plates are vast and varied. They are commonly used in industrial environments, such as factories, power plants, and oil refineries, where safety and durability are paramount. Grating plates provide secure walking surfaces, drain covers, and walkways—helping to prevent slips and falls in areas that may be exposed to grease, water, or other hazardous materials.

In construction, these plates can be used as flooring for platforms, catwalks, and loading docks. The open design allows for the easy passage of light, heat, and air, making them an efficient choice for many applications. Additionally, the strength of steel grating ensures that they can withstand heavy loads, making them suitable for areas with high foot traffic or heavy machinery.

steel grating plate

Advantages of Steel Grating Plates

One of the primary benefits of steel grating plates is their strength-to-weight ratio. Though they are lightweight compared to solid steel plates, they still provide excellent load-bearing capabilities. This means that less material is needed, which can lead to cost savings in production and transportation.

Another advantage is their corrosion resistance, especially when manufactured with galvanized or stainless steel. This quality makes them ideal for outdoor or harsh environments where they may be exposed to the elements. The open structure of grating plates also ensures that water and debris can easily flow through, reducing the risk of buildup and potential hazards.

Maintenance is another area where steel grating plates excel. Their design minimizes the accumulation of dirt and debris, which can be easily cleaned, ensuring a safer environment for workers and visitors. Furthermore, they are often designed to be slip-resistant, providing additional safety in wet or oily conditions.

Choosing the Right Steel Grating Plate

When selecting the appropriate steel grating plate for a project, several factors must be considered. These include the intended application, load requirements, the environment in which they will be used, and any regulatory or safety standards that must be met. The spacing between the bars, thickness, and material type are essential attributes that need careful consideration.

In summary, steel grating plates are a staple in modern engineering, providing essential functionality and safety across various applications. Their lightweight design, coupled with exceptional strength and corrosion resistance, makes them suitable for numerous environments. As industries continue to evolve, so too will the innovations in steel grating technology, ensuring these vital components remain at the forefront of construction and industrial design for years to come. Whether you are an engineer, architect, or builder, understanding the features and benefits of steel grating plates can help you make informed decisions for your projects and ensure the safety and efficiency of your structures.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024