- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 02:04

Back to list

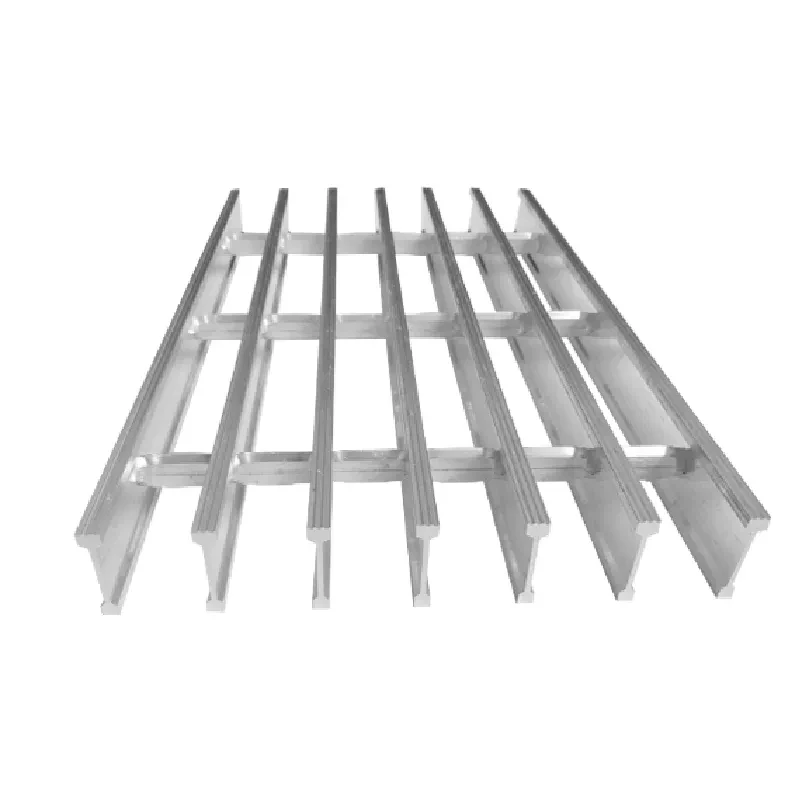

Steel Grating

Steel grating plates have become an indispensable component in various industries due to their robustness, durability, and versatility. Made from steel bars, these plates form a grid-like pattern with intersecting lines of steel, providing a strong and solid framework for a multitude of applications.

From an aesthetics perspective, steel grating plates are instrumental in modern architectural designs. Their ability to provide an industrial yet sleek look adds a contemporary edge to buildings and outdoor spaces. Artists and designers have also started incorporating these plates into their works, pushing the boundaries of functional art. Steel grating plates have also made significant inroads in public infrastructure. Used in bridges, highway drain covers, and ventilation grilles, they provide transparency and natural light flow while maintaining structural integrity. Their easy installation and low maintenance needs make them a cost-effective choice for public works. The expert use of steel grating plates is not confined to industrial or infrastructural applications alone. Their adaptability sees them employed in varied contexts such as animal enclosures in zoos, where their high strength-to-weight ratio and robustness provide secure containment without obstructing views or restricting airflow. When procuring steel grating plates, it’s crucial to engage with reputable manufacturers who can assure material quality and adherence to industry standards. Certification and compliance with safety regulations are key indicators of a trustworthy supplier. Prospective buyers should also seek companies with a history of successful project implementations and positive customer testimonials to validate their expertise and reliability. In conclusion, the multifaceted applications and advantages of steel grating plates underscore their status as an essential material in modern industry. Their strength, durability, and sustainable nature, combined with a wide range of customization options, ensure that they remain a top choice for architects, engineers, and designers worldwide. Whether for industrial use, public infrastructure, or artistic expression, steel grating plates offer unparalleled performance and reliability.

From an aesthetics perspective, steel grating plates are instrumental in modern architectural designs. Their ability to provide an industrial yet sleek look adds a contemporary edge to buildings and outdoor spaces. Artists and designers have also started incorporating these plates into their works, pushing the boundaries of functional art. Steel grating plates have also made significant inroads in public infrastructure. Used in bridges, highway drain covers, and ventilation grilles, they provide transparency and natural light flow while maintaining structural integrity. Their easy installation and low maintenance needs make them a cost-effective choice for public works. The expert use of steel grating plates is not confined to industrial or infrastructural applications alone. Their adaptability sees them employed in varied contexts such as animal enclosures in zoos, where their high strength-to-weight ratio and robustness provide secure containment without obstructing views or restricting airflow. When procuring steel grating plates, it’s crucial to engage with reputable manufacturers who can assure material quality and adherence to industry standards. Certification and compliance with safety regulations are key indicators of a trustworthy supplier. Prospective buyers should also seek companies with a history of successful project implementations and positive customer testimonials to validate their expertise and reliability. In conclusion, the multifaceted applications and advantages of steel grating plates underscore their status as an essential material in modern industry. Their strength, durability, and sustainable nature, combined with a wide range of customization options, ensure that they remain a top choice for architects, engineers, and designers worldwide. Whether for industrial use, public infrastructure, or artistic expression, steel grating plates offer unparalleled performance and reliability.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024