- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 05, 2025 04:59

Back to list

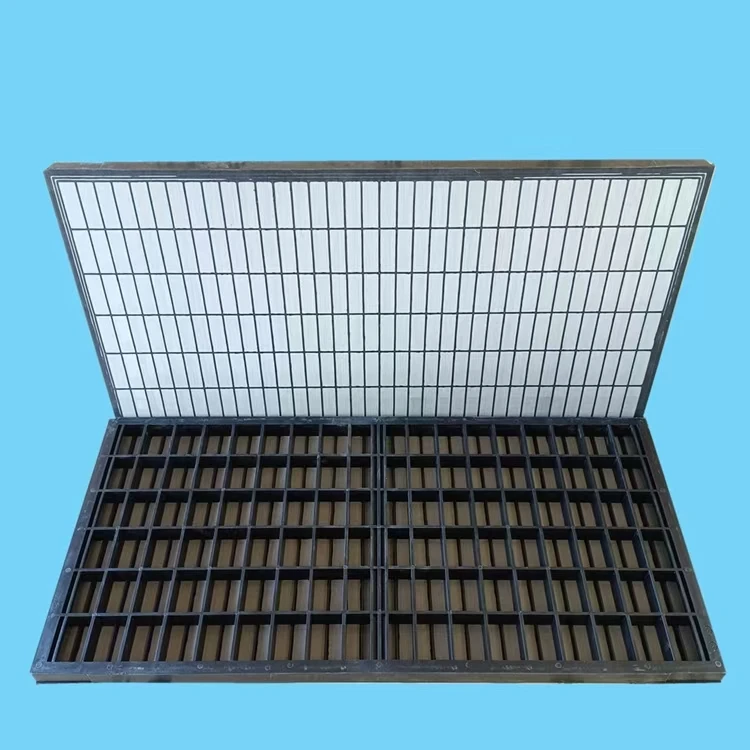

Steel Grating

Steel grating mesh is a staple in industrial and commercial settings, recognized for its durability, strength, and versatility. As a specialist in the field, I aim to provide an in-depth exploration of its benefits and applications, coupled with my personal experiences and insights that enhance its value proposition.

Trustworthiness in any product comes from its performance over time, a criterion that steel grating mesh consistently meets. Its low maintenance needs—thanks to the corrosion-resistant properties of galvanized and stainless variants—promise long-term cost savings. Clients have often highlighted the economic advantages of using steel grating mesh over alternative materials, noting reduced repair and replacement costs. Moreover, sustainability is an increasing concern in modern applications. Steel grating mesh is entirely recyclable, aligning with environmental stewardship goals. My work in sustainable construction projects has often involved recommending steel grating due to its environmentally friendly attributes, thereby supporting both industry standards and ecological responsibilities. To solidify its authoritative presence, it’s essential to partner with reputable suppliers who guarantee compliance with international quality standards such as ISO, ASTM, or BS. My collaborations with such suppliers have ensured that clients receive products that perform flawlessly even under stringent conditions. In conclusion, steel grating mesh stands out as a versatile and reliable solution across various industries. Its applications are as diverse as they are numerous, driven by its inherent strength, flexibility, and cost-effectiveness. By sharing my expertise and experiences, I hope to provide a comprehensive understanding of how steel grating mesh can meet and exceed operational needs, helping businesses to maintain safe, efficient, and environmentally responsible practices.

Trustworthiness in any product comes from its performance over time, a criterion that steel grating mesh consistently meets. Its low maintenance needs—thanks to the corrosion-resistant properties of galvanized and stainless variants—promise long-term cost savings. Clients have often highlighted the economic advantages of using steel grating mesh over alternative materials, noting reduced repair and replacement costs. Moreover, sustainability is an increasing concern in modern applications. Steel grating mesh is entirely recyclable, aligning with environmental stewardship goals. My work in sustainable construction projects has often involved recommending steel grating due to its environmentally friendly attributes, thereby supporting both industry standards and ecological responsibilities. To solidify its authoritative presence, it’s essential to partner with reputable suppliers who guarantee compliance with international quality standards such as ISO, ASTM, or BS. My collaborations with such suppliers have ensured that clients receive products that perform flawlessly even under stringent conditions. In conclusion, steel grating mesh stands out as a versatile and reliable solution across various industries. Its applications are as diverse as they are numerous, driven by its inherent strength, flexibility, and cost-effectiveness. By sharing my expertise and experiences, I hope to provide a comprehensive understanding of how steel grating mesh can meet and exceed operational needs, helping businesses to maintain safe, efficient, and environmentally responsible practices.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024