- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 05:37

Back to list

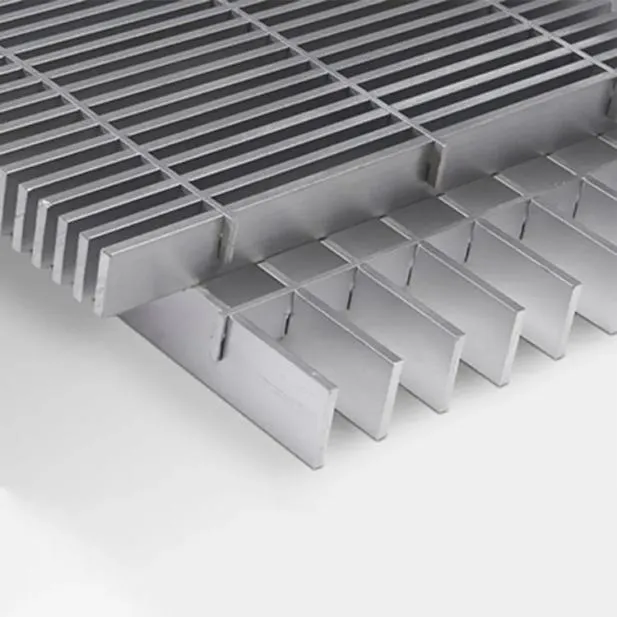

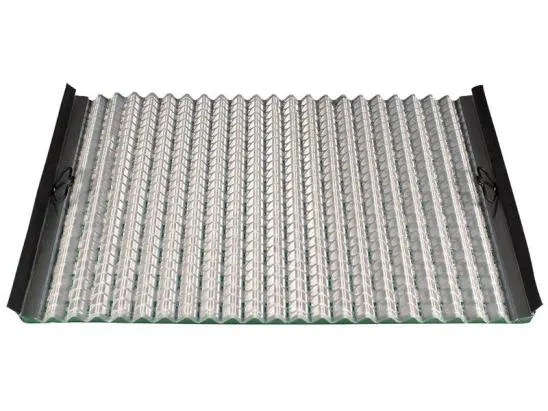

steel walkway grating

Steel grating mesh represents a versatile and essential component in the industrial and construction sectors, valued not only for its sturdy architecture but also its remarkable adaptability and safety features. As an industry professional, understanding the nuanced benefits of steel grating mesh can fundamentally influence the success of your projects, whether in heavy-duty manufacturing settings or delicate architectural endeavors.

Trustworthiness in steel grating mesh is achieved through a transparent manufacturing process and rigorous quality control measures. Partnering with reputable suppliers who provide certification and testing documentation can alleviate concerns about product integrity. Before purchasing, insist on reviewing compliance records and performance reviews. This vigilance not only secures investment but also reassures clients of safety and reliability. The versatility of steel grating mesh is further demonstrated in architectural applications, where it offers aesthetic flexibility combined with structural integrity. Architects frequently incorporate steel grating in designs that require an industrial yet modern aesthetic. Its ability to diffuse light, regulate temperature, and even improve acoustics makes it an advantageous choice in commercial buildings, bridges, and public spaces. Technological advances have introduced sophisticated coating techniques that extend the lifespan of steel grating and enhance its resistance to environmental corrosives, thereby increasing its application scope. Powder-coated steel grating, for instance, provides a vibrant finish and additional protection against abrasion, making it suitable for commercial and residential use. For professionals considering steel grating mesh, embracing a comprehensive strategy that considers material selection, compliance with standards, and supplier reliability is essential. Strategic implementation not only optimizes safety and functionality but also contributes to the overarching goals of project sustainability and economic efficiency. In the spectrum of industrial and construction materials, steel grating mesh stands out not merely for its physical properties but for its contributions to modern infrastructure. Its role in enhancing safety, its compliance with environmental standards, and its adaptability to contemporary design challenges underscore its indispensable value and future prospects in a rapidly evolving world.

Trustworthiness in steel grating mesh is achieved through a transparent manufacturing process and rigorous quality control measures. Partnering with reputable suppliers who provide certification and testing documentation can alleviate concerns about product integrity. Before purchasing, insist on reviewing compliance records and performance reviews. This vigilance not only secures investment but also reassures clients of safety and reliability. The versatility of steel grating mesh is further demonstrated in architectural applications, where it offers aesthetic flexibility combined with structural integrity. Architects frequently incorporate steel grating in designs that require an industrial yet modern aesthetic. Its ability to diffuse light, regulate temperature, and even improve acoustics makes it an advantageous choice in commercial buildings, bridges, and public spaces. Technological advances have introduced sophisticated coating techniques that extend the lifespan of steel grating and enhance its resistance to environmental corrosives, thereby increasing its application scope. Powder-coated steel grating, for instance, provides a vibrant finish and additional protection against abrasion, making it suitable for commercial and residential use. For professionals considering steel grating mesh, embracing a comprehensive strategy that considers material selection, compliance with standards, and supplier reliability is essential. Strategic implementation not only optimizes safety and functionality but also contributes to the overarching goals of project sustainability and economic efficiency. In the spectrum of industrial and construction materials, steel grating mesh stands out not merely for its physical properties but for its contributions to modern infrastructure. Its role in enhancing safety, its compliance with environmental standards, and its adaptability to contemporary design challenges underscore its indispensable value and future prospects in a rapidly evolving world.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024