- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

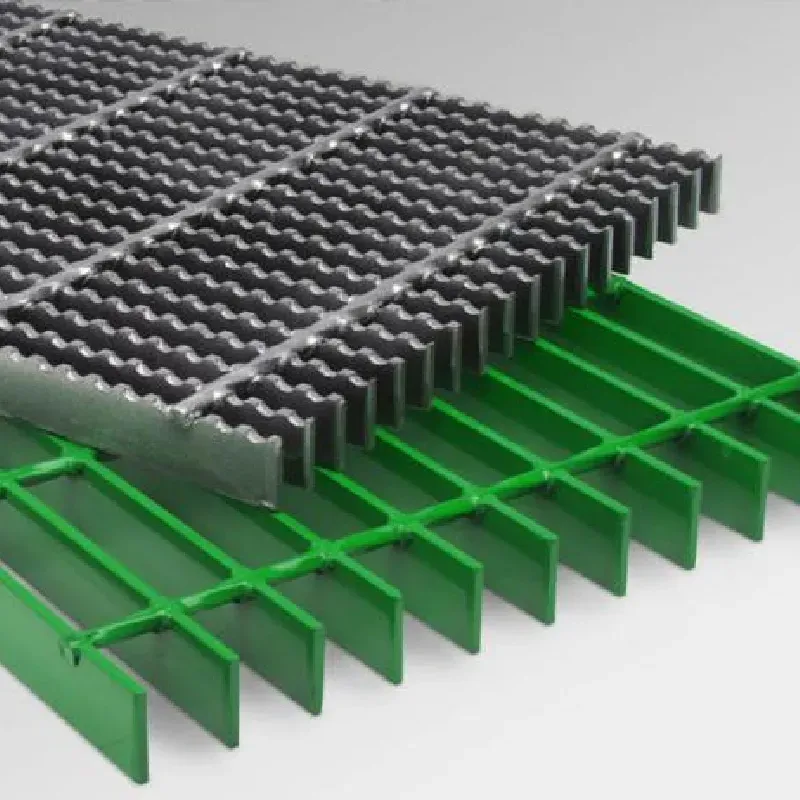

Galvanized Steel Grating for Durable and Corrosion-Resistant Industrial Applications

The Importance of Galvanized Steel Grating in Modern Construction

Steel grating, particularly when galvanized, has become a staple in various construction and industrial applications due to its unique properties and versatility. This article explores the significance of galvanized steel grating, its manufacturing process, benefits, and its wide range of uses across different sectors.

What is Steel Grating?

Steel grating is a type of flat material, commonly used in flooring, walkways, and load-bearing surfaces. It is composed of a series of parallel bars that are welded or forged together to create a strong, open-framework structure. This allows for easy drainage, ventilation, and visibility while providing robust support for heavy loads.

The Galvanization Process

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rust and corrosion. This method is essential for steel grating, as these structures are often exposed to harsh environmental conditions, including moisture, chemicals, and varying temperatures. The galvanization process typically involves either hot-dip galvanizing or electro-galvanizing, with hot-dip galvanizing being the most common method. In hot-dip galvanizing, steel grating is submerged in molten zinc, which forms a durable and corrosion-resistant coating that adheres tightly to the steel surface.

Benefits of Galvanized Steel Grating

1. Corrosion Resistance One of the primary advantages of galvanized steel grating is its resistance to corrosion. The zinc coating acts as a barrier that protects the underlying steel from moisture and environmental contaminants, prolonging the lifespan of the structure.

2. Durability Galvanized steel grating is incredibly strong and durable. It can withstand heavy loads and foot traffic, making it suitable for industrial environments, such as factories, warehouses, and distribution centers.

steel grating galvanized

3. Low Maintenance Due to its corrosion-resistant properties, galvanized steel grating requires minimal maintenance. Regular inspections and occasional cleaning are usually sufficient to keep it in good condition.

4. Safety The open design of steel grating allows for excellent drainage, reducing the risk of water accumulation and slip hazards. Moreover, its sturdy design provides a secure walking surface for pedestrians and workers.

5. Versatility Galvanized steel grating can be customized to meet specific needs, including size, spacing, and thickness. This versatility allows it to be used in various applications, from pedestrian walkways to heavy-duty industrial platforms.

6. Cost-Effectiveness While the initial cost of galvanized steel grating may be higher than that of untreated steel, the long-term savings in maintenance and replacement costs make it a cost-effective choice. Its extended lifespan means fewer replacements are needed, ultimately saving money over time.

Applications of Galvanized Steel Grating

Galvanized steel grating is used in a wide range of settings, including

- Industrial Facilities Commonly found in factories, oil refineries, and power plants, where it is used for flooring, platforms, and walkways. - Commercial Buildings Utilized in commercial spaces for staircases, drainage covers, and ventilation grates. - Municipal Applications Employed in public infrastructure, including sidewalks, bridges, and parks, enhancing safety and accessibility. - Transportation Used in railway and airport facilities for pedestrian walkways and vehicle ramps.

Conclusion

In conclusion, galvanized steel grating is an essential component in modern construction that combines strength, durability, and safety. Its corrosion-resistant properties make it well-suited for various environments, ensuring longevity and low maintenance costs. As industries continue to seek efficient and reliable solutions for structural and safety needs, galvanized steel grating will undoubtedly remain a preferred choice in construction and industrial applications. Its versatility and effectiveness highlight the importance of this material in creating safe and sustainable workspaces.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024