- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 05, 2025 00:34

Back to list

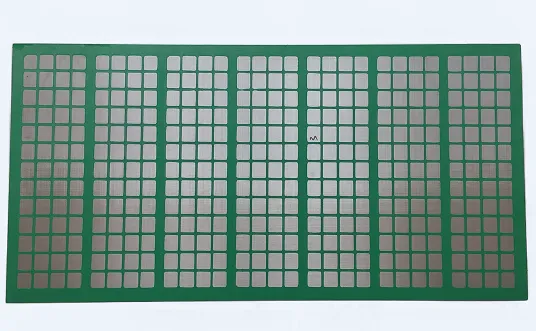

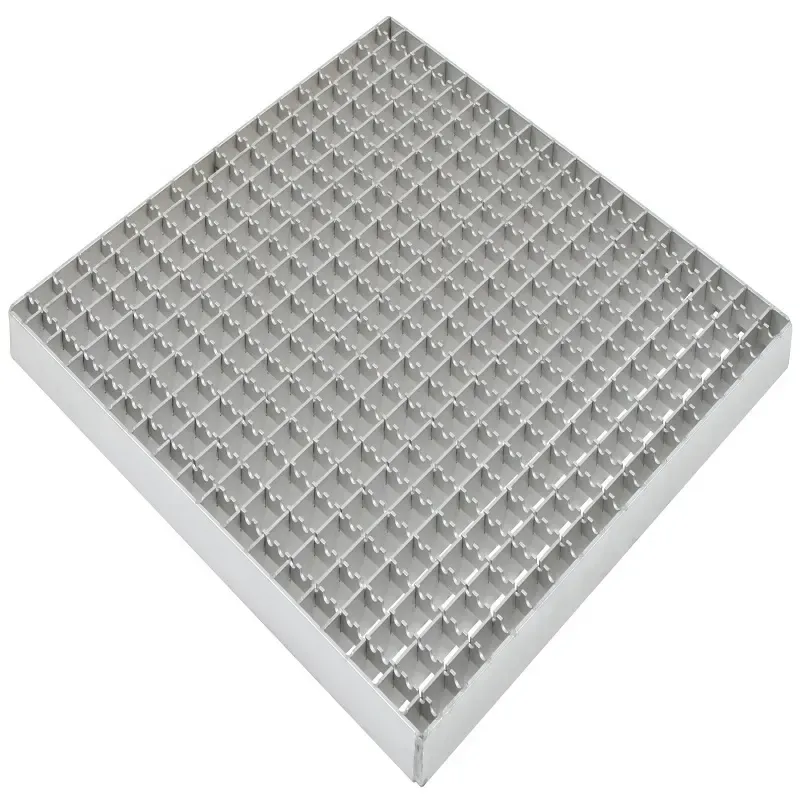

steel grating galvanis

Steel grating is a vital component across various industries, and its significance is underscored by the need for robust, durable, and safe solutions. As one of the most trusted materials, galvanised steel grating offers unmatched benefits in platforms, walkways, stair treads, and drainage covers. With years of experience in manufacturing and engineering, the critical role of galvanised steel grating cannot be overstated.

Galvanised steel grating is not just about industrial use; it's also about sustainability and environmental responsibility. The protective zinc coating prolongs the life of steel grating, thereby reducing the need for frequent replacements and conserving resources. Recyclability, another defining characteristic of steel, aligns with many industries' drive towards sustainable practices, further increasing trustworthiness among environmentally conscious businesses. Moreover, the maintenance aspect of galvanised steel grating is minimal, which translates to lower operation costs. For industries looking to maximise uptime and efficiency, this is a noteworthy advantage. The resilience of galvanised grating against extreme temperatures, moisture, and chemical exposure ensures that maintenance interventions are infrequent. Safety is undeniably a paramount concern across industrial applications, and galvanised steel grating provides a safe surface with excellent slip resistance. Tested rigorously, these gratings help prevent accidents even in the most demanding conditions, thus safeguarding workers and minimizing industrial mishaps. In conclusion, galvanised steel grating stands out as a testament to quality and durability. Its broad applications, adherence to international standards, and environmental friendliness position it as a pivotal element in industrial and architectural projects. By investing in galvanised steel grating, industries align with modern demands for safety, sustainability, and cost-effectiveness, securing the trust and confidence of stakeholders worldwide.

Galvanised steel grating is not just about industrial use; it's also about sustainability and environmental responsibility. The protective zinc coating prolongs the life of steel grating, thereby reducing the need for frequent replacements and conserving resources. Recyclability, another defining characteristic of steel, aligns with many industries' drive towards sustainable practices, further increasing trustworthiness among environmentally conscious businesses. Moreover, the maintenance aspect of galvanised steel grating is minimal, which translates to lower operation costs. For industries looking to maximise uptime and efficiency, this is a noteworthy advantage. The resilience of galvanised grating against extreme temperatures, moisture, and chemical exposure ensures that maintenance interventions are infrequent. Safety is undeniably a paramount concern across industrial applications, and galvanised steel grating provides a safe surface with excellent slip resistance. Tested rigorously, these gratings help prevent accidents even in the most demanding conditions, thus safeguarding workers and minimizing industrial mishaps. In conclusion, galvanised steel grating stands out as a testament to quality and durability. Its broad applications, adherence to international standards, and environmental friendliness position it as a pivotal element in industrial and architectural projects. By investing in galvanised steel grating, industries align with modern demands for safety, sustainability, and cost-effectiveness, securing the trust and confidence of stakeholders worldwide.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024