- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

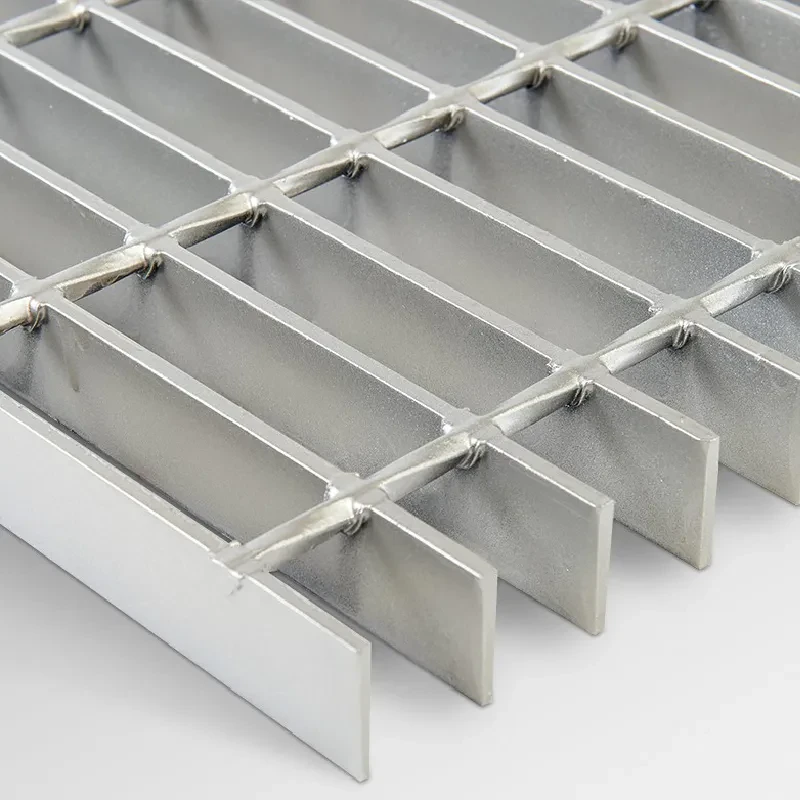

steel grating floor

The Advantages and Applications of Steel Grating Floors

In various industrial and commercial settings, the choice of flooring material significantly impacts functional performance and safety. Among the many available options, steel grating floors have gained popularity for their remarkable strength, durability, and versatility. This article delves into the advantages and applications of steel grating floors, illustrating their importance in modern infrastructure.

What is Steel Grating?

Steel grating is a construction material made from crossbars and bearing bars that create a grid-like structure. Typically manufactured from carbon steel, stainless steel, or aluminum, these gratings can be designed to meet specific load-bearing requirements and environmental conditions. The most common types include welded and swaged grating, each tailored for particular applications.

1. Strength and Durability

One of the most significant advantages of steel grating floors is their exceptional strength. Steel can withstand heavy loads, making it ideal for high-traffic areas in various industries, such as manufacturing plants, warehouses, and commercial facilities. Additionally, these floors are resistant to impact and wear, offering long-term durability with minimal maintenance. Their ability to withstand harsh conditions—such as extreme temperatures, chemical exposure, and heavy machinery—further enhances their appeal.

Steel grating floors are designed with safety in mind. The open grid structure allows for excellent drainage, minimizing slip hazards caused by liquids pooling on the surface. Anti-slip coatings can be applied to enhance traction, ensuring adequate grip even in wet conditions. Furthermore, the visibility of the grating allows for light penetration, improving workplace illumination and reducing the risk of accidents.

3. Versatility in Design

steel grating floor

Steel grating floors are versatile and can be customized to fit any space. They can be produced in various sizes, depths, and load ratings to accommodate different applications. Whether it’s a catwalk, platform, walkway, or stair tread, steel grating can be molded and adapted to suit specific design requirements. Their modular design makes installation and replacement straightforward, which is often a significant factor in renovation projects.

4. Cost-Effectiveness

While the initial cost of steel grating floors may be higher than alternative materials, the long-term benefits often outweigh the initial investment. Their durability leads to lower repair and replacement costs over time. Additionally, their resistance to environmental factors reduces the need for protective coatings or floor treatments, further contributing to overall cost savings.

5. Eco-Friendly Option

Steel grating is a recyclable material, making it an eco-friendly choice for environmentally conscious projects. The production of steel grating uses a smaller amount of material compared to solid flooring options, leading to reduced waste. As industries move towards more sustainable practices, steel grating stands out as a responsible choice that supports eco-friendly initiatives.

Applications of Steel Grating Floors

Steel grating floors are widely used across various sectors. In industrial environments, they are often found in loading docks, process areas, assembly lines, and maintenance platforms. In commercial settings, they serve as flooring for stairways, balconies, and walkways. Additionally, steel grating is also employed in transportation infrastructure, such as bridges and platforms in train stations, due to its strength and resistance to outdoor elements.

Conclusion

Steel grating floors offer an array of advantages that make them an excellent choice for numerous applications. Their strength, safety features, design versatility, cost-effectiveness, and eco-friendliness position them as a preferred flooring solution in various industries. As modern construction continues to evolve, the use of steel grating floors is expected to become increasingly prevalent, contributing to safer and more efficient work environments. With the right maintenance and care, these floors can provide lasting benefits for decades, making them a valuable investment for any industrial or commercial facility.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024