- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 11:18

Back to list

steel grating cost per square foot

Understanding the steel grating cost per square foot involves various intricate elements that are crucial for making informed purchasing decisions. Steel grating, prevalent in industrial and commercial settings, provides a robust and durable option for flooring, walkways, and platforms. Despite its popularity, comprehending its cost structure can be challenging for newcomers and experienced purchasers alike. Here is an in-depth look into the various factors affecting the cost and the value it offers.

5. Manufacturing and Labor Costs Regional variations in labor and manufacturing costs can lead to significant differences in pricing. Facilities that employ advanced manufacturing techniques and technology may offer more competitive pricing due to increased efficiency and reduced waste during production. 6. Volume and Customization Needs Purchasing in bulk often leads to a lower cost per square foot, as manufacturers are able to pass on the savings associated with larger production runs. Additionally, projects requiring custom sizes or shapes might see a higher cost due to the specialized nature of the cutting and shaping processes involved. 7. Supplier Reliability and Delivery Logistics Choosing a reputable supplier with a proven track record can ensure quality and reliability, though it might come at a premium. Delivery logistics, including distance from the manufacturing facility and shipping conditions, also affect the total cost. Buyers should consider the timing and geographic location of their projects when calculating the potential costs of transportation and delivery. While price is a crucial factor, the benefits steel grating provides often justify the investment. Its versatility, coupled with low maintenance requirements and high resistance to wear and tear, ensures value over time. For environments where safety and durability are prioritized, such as factories, industrial plants, and public infrastructure, steel grating emerges as an unrivaled choice. When evaluating steel grating options, it's essential to examine the initial cost alongside the long-term savings in maintenance and replacements. By partnering with knowledgeable suppliers and leveraging their expertise, buyers can optimize their purchases to align with both budgetary constraints and performance requirements. A strategic approach to understanding these variables will not only help in managing expenses but also enhance the operational efficiency and safety of infrastructure projects. Overall, the cost per square foot for steel grating is a complex interplay of multiple factors, each contributing to the final price. By dissecting each element, stakeholders can make well-informed decisions, ensuring alignment with both project specifications and budget goals. The resulting investment in quality steel grating pays dividends in longevity, reduced downtime due to maintenance issues, and enhanced structural integrity.

5. Manufacturing and Labor Costs Regional variations in labor and manufacturing costs can lead to significant differences in pricing. Facilities that employ advanced manufacturing techniques and technology may offer more competitive pricing due to increased efficiency and reduced waste during production. 6. Volume and Customization Needs Purchasing in bulk often leads to a lower cost per square foot, as manufacturers are able to pass on the savings associated with larger production runs. Additionally, projects requiring custom sizes or shapes might see a higher cost due to the specialized nature of the cutting and shaping processes involved. 7. Supplier Reliability and Delivery Logistics Choosing a reputable supplier with a proven track record can ensure quality and reliability, though it might come at a premium. Delivery logistics, including distance from the manufacturing facility and shipping conditions, also affect the total cost. Buyers should consider the timing and geographic location of their projects when calculating the potential costs of transportation and delivery. While price is a crucial factor, the benefits steel grating provides often justify the investment. Its versatility, coupled with low maintenance requirements and high resistance to wear and tear, ensures value over time. For environments where safety and durability are prioritized, such as factories, industrial plants, and public infrastructure, steel grating emerges as an unrivaled choice. When evaluating steel grating options, it's essential to examine the initial cost alongside the long-term savings in maintenance and replacements. By partnering with knowledgeable suppliers and leveraging their expertise, buyers can optimize their purchases to align with both budgetary constraints and performance requirements. A strategic approach to understanding these variables will not only help in managing expenses but also enhance the operational efficiency and safety of infrastructure projects. Overall, the cost per square foot for steel grating is a complex interplay of multiple factors, each contributing to the final price. By dissecting each element, stakeholders can make well-informed decisions, ensuring alignment with both project specifications and budget goals. The resulting investment in quality steel grating pays dividends in longevity, reduced downtime due to maintenance issues, and enhanced structural integrity.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

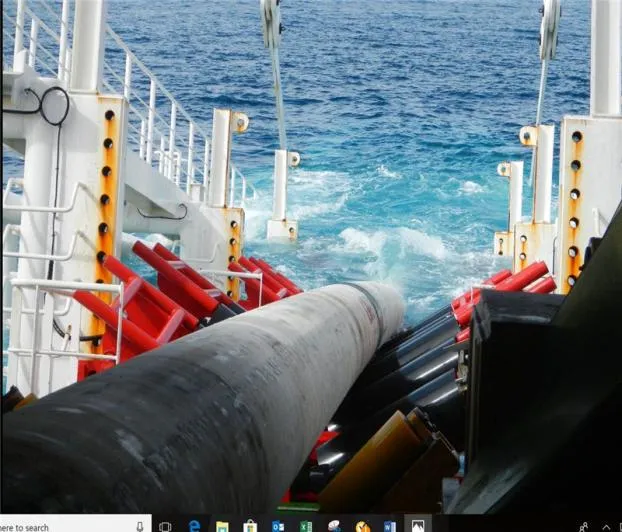

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024