- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 12:34

Back to list

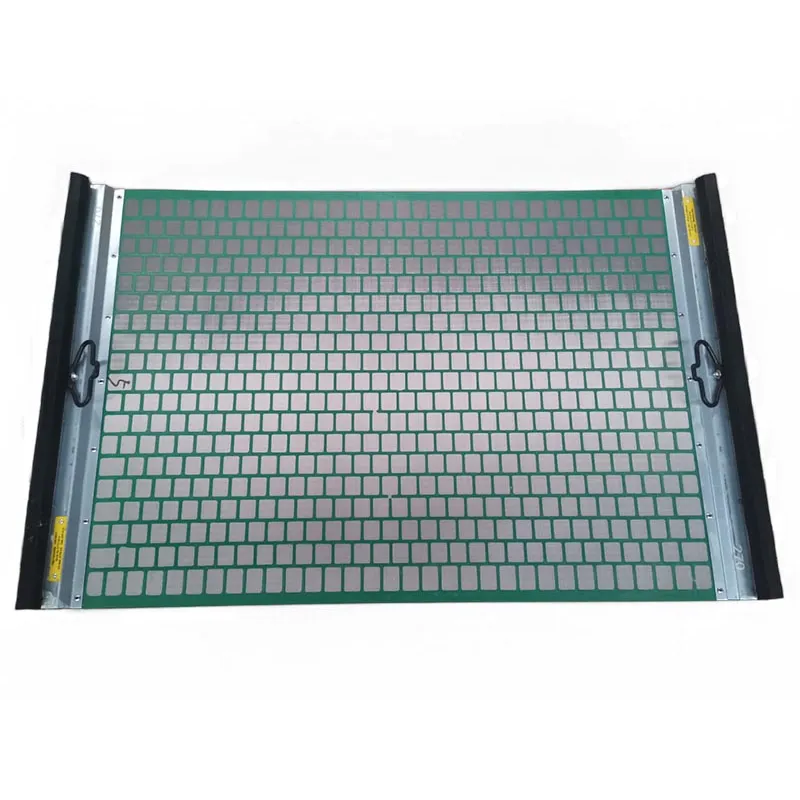

steel grating cost

Understanding the cost dynamics of steel grating is vital for businesses and industries that rely heavily on durable, reliable materials for construction and various applications. Steel grating is an essential component in numerous sectors, from industrial flooring to walkways on ships. The expertise required to navigate the complexities of its costs involves acknowledging various factors that influence pricing.

Furthermore, logistical considerations can impact overall expenses. Shipping and handling costs can vary depending on the size and weight of the order, as well as the distance between the manufacturer and the destination site. Choosing local suppliers, when possible, can reduce transportation costs and delivery times, which is particularly advantageous for projects with tight schedules. The expertise of a seasoned engineer or consultant is invaluable when assessing steel grating costs. They can provide authoritative advice on selecting the appropriate grating type and specifications suitable for specific applications, ensuring safety and compliance with industry standards. By leveraging professional insights, businesses can avoid over-specifying or under-specifying their needs, thus optimizing both performance and cost-efficiency. Trustworthiness in the context of steel grating procurement involves dealing with reliable manufacturers known for product quality and adherence to international standards. Engaging with well-established companies or those that have achieved certifications such as ISO can assure the business of consistent product quality and reliable supply chains. In conclusion, navigating steel grating costs involves a comprehensive consideration of material types, manufacturing processes, custom needs, market conditions, logistical aspects, and professional guidance. By adopting a strategic approach that incorporates expertise, experience, authoritativeness, and trustworthiness, businesses can achieve optimal results both financially and operationally. The strategic partnership with expert manufacturers and consultants will serve as a robust foundation for informed decision-making in streamlined, cost-effective projects.

Furthermore, logistical considerations can impact overall expenses. Shipping and handling costs can vary depending on the size and weight of the order, as well as the distance between the manufacturer and the destination site. Choosing local suppliers, when possible, can reduce transportation costs and delivery times, which is particularly advantageous for projects with tight schedules. The expertise of a seasoned engineer or consultant is invaluable when assessing steel grating costs. They can provide authoritative advice on selecting the appropriate grating type and specifications suitable for specific applications, ensuring safety and compliance with industry standards. By leveraging professional insights, businesses can avoid over-specifying or under-specifying their needs, thus optimizing both performance and cost-efficiency. Trustworthiness in the context of steel grating procurement involves dealing with reliable manufacturers known for product quality and adherence to international standards. Engaging with well-established companies or those that have achieved certifications such as ISO can assure the business of consistent product quality and reliable supply chains. In conclusion, navigating steel grating costs involves a comprehensive consideration of material types, manufacturing processes, custom needs, market conditions, logistical aspects, and professional guidance. By adopting a strategic approach that incorporates expertise, experience, authoritativeness, and trustworthiness, businesses can achieve optimal results both financially and operationally. The strategic partnership with expert manufacturers and consultants will serve as a robust foundation for informed decision-making in streamlined, cost-effective projects.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024