- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 10, 2025 17:52

Back to list

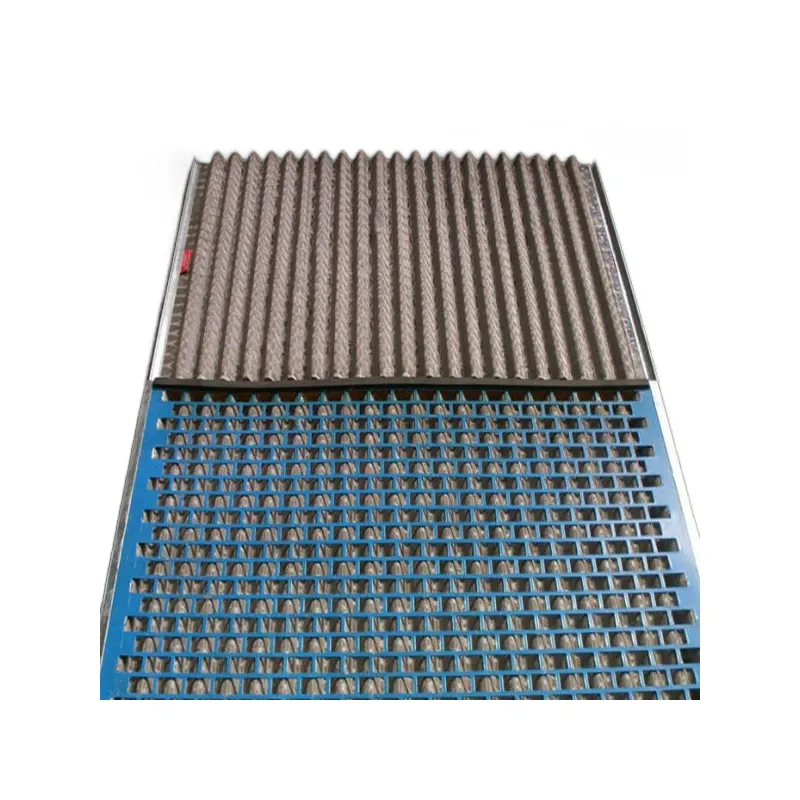

Steel Grating

Steel grating is an essential component in modern construction and industrial applications, known for its strength, durability, and multifunctionality. As an experienced construction engineer well-versed in industry standards and the latest innovations, I aim to provide an in-depth look at the advantages and applications of steel grating, showcasing its reliability and trustworthiness.

From an expertise standpoint, selecting the appropriate type of steel grating requires a comprehensive understanding of the specific environment and use-case scenarios. For example, in situations with high humidity or exposure to chemicals, the material's resistance to environmental factors must be thoroughly evaluated. Experts recommend collaborating with grating manufacturers and suppliers who offer customized solutions and have a proven track record of delivering quality products. Faith in steel grating shouldn't solely reside in sales pitches or manufacturer claims; instead, it should be backed by internationally recognized standards and certifications. Looking for compliance with ISO, ASTM, or EN standards ensures that the grating has been produced to meet rigorous quality and safety requirements. This offers a layer of trustworthiness that is imperative in today's construction and industrial sectors. Expert installation is another critical component that enhances the reliability and safety of steel grating. Professionals with years of experience can ensure that the grating is securely installed, reducing the risk of accidents due to poor installation practices. Regular maintenance and inspection further augment its longevity, ensuring that the grating continues to perform optimally under various conditions. Personal experiences of engineers and construction managers highlight the transformative role steel grating plays in projects. For instance, in a recent project for a sewage treatment plant, the use of hot-dip galvanized steel grating provided both the necessary durability and resistance to the corrosive environment, while also ensuring worker safety with non-slip surfaces. In conclusion, steel grating stands out as a remarkable product due to its versatility, strength, and cost-efficiency. It is a trusted component across a wide range of industries due to its proven performance and adaptability. Understanding the specific needs and conditions of each application enables professionals to make informed decisions, ensuring that the steel grating delivers unparalleled satisfaction and service life. Through knowledge, experience, and adherence to industry standards, steel grating continues to evolve as an essential element in meeting modern construction and industrial demands.

From an expertise standpoint, selecting the appropriate type of steel grating requires a comprehensive understanding of the specific environment and use-case scenarios. For example, in situations with high humidity or exposure to chemicals, the material's resistance to environmental factors must be thoroughly evaluated. Experts recommend collaborating with grating manufacturers and suppliers who offer customized solutions and have a proven track record of delivering quality products. Faith in steel grating shouldn't solely reside in sales pitches or manufacturer claims; instead, it should be backed by internationally recognized standards and certifications. Looking for compliance with ISO, ASTM, or EN standards ensures that the grating has been produced to meet rigorous quality and safety requirements. This offers a layer of trustworthiness that is imperative in today's construction and industrial sectors. Expert installation is another critical component that enhances the reliability and safety of steel grating. Professionals with years of experience can ensure that the grating is securely installed, reducing the risk of accidents due to poor installation practices. Regular maintenance and inspection further augment its longevity, ensuring that the grating continues to perform optimally under various conditions. Personal experiences of engineers and construction managers highlight the transformative role steel grating plays in projects. For instance, in a recent project for a sewage treatment plant, the use of hot-dip galvanized steel grating provided both the necessary durability and resistance to the corrosive environment, while also ensuring worker safety with non-slip surfaces. In conclusion, steel grating stands out as a remarkable product due to its versatility, strength, and cost-efficiency. It is a trusted component across a wide range of industries due to its proven performance and adaptability. Understanding the specific needs and conditions of each application enables professionals to make informed decisions, ensuring that the steel grating delivers unparalleled satisfaction and service life. Through knowledge, experience, and adherence to industry standards, steel grating continues to evolve as an essential element in meeting modern construction and industrial demands.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024