- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

steel bar grating weight

Understanding Steel Bar Grating Weight A Comprehensive Guide

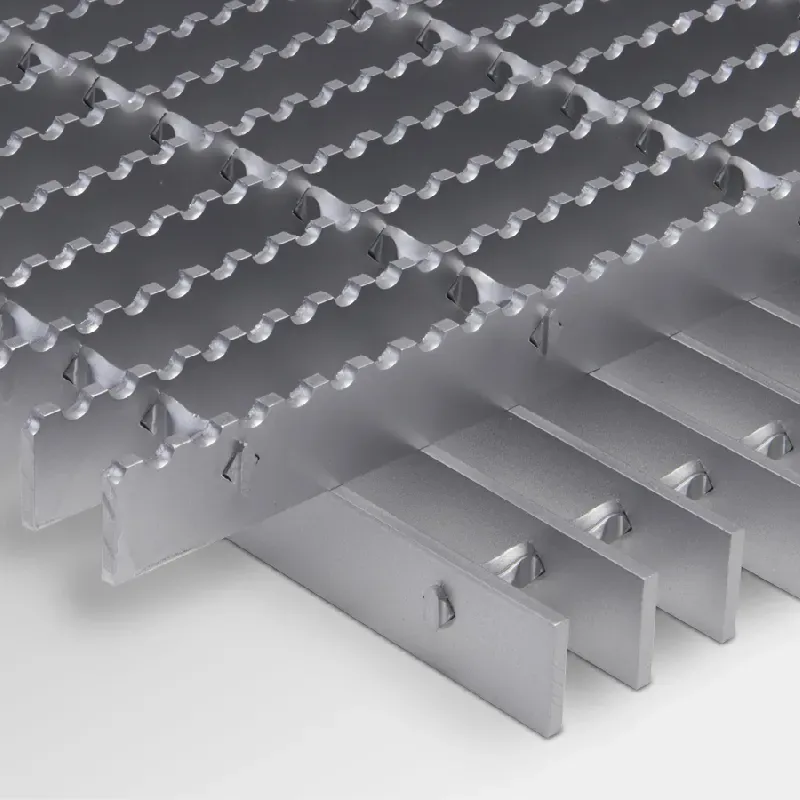

Steel bar grating is a widely used material in various applications, from industrial flooring to walkways, drainage covers, and platform supports. Its durability and strength make it a popular choice in both construction and maintenance. However, one essential aspect that often requires careful consideration is the weight of the steel bar grating. Understanding its weight is crucial for proper installation, load capacity assessments, and ensuring the safety and reliability of structures. This article delves into the factors influencing the weight of steel bar grating, its specifications, and its practical implications in various applications.

What is Steel Bar Grating?

Steel bar grating, also known as metal bar grating or simply grating, consists of a series of parallel bars running in one direction, with crossbars welded or riveted at regular intervals to provide support and stability. This design allows for high load-bearing capacity while promoting water drainage and allowing for light and airflow. Steel grating is commonly made from carbon steel, stainless steel, or aluminum, each with its advantages depending on the application.

Factors Influencing Weight

The weight of steel bar grating can be influenced by several factors

1. Material Type The choice of material affects the overall weight. For instance, stainless steel grating is heavier than aluminum but offers superior corrosion resistance.

2. Bar Thickness Thicker bars increase the weight of the grating. The thickness required generally depends on the anticipated load and the spacing of the bars.

3. Bar Spacing The distance between the bars affects how much material is needed. Closer spacing can lead to a heavier grating, while wider spacing will reduce the weight but may impact load-bearing capabilities.

4. Length and Width The overall dimensions of the grating panel are crucial. Longer and wider panels will naturally weigh more than smaller ones.

5. Coating Additional coatings or treatments (like galvanization) not only provide protection from corrosion but can also add weight to the final product.

Weight Calculation

steel bar grating weight

To calculate the weight of steel bar grating, manufacturers often provide weight per square foot or per square meter, making it easier for engineers and contractors to assess the total weight based on how much grating they need for a specific project. The following formula can be applied

\[ \text{Weight} = \text{Area} \times \text{Weight per Unit Area} \]

For example, if a steel bar grating has a weight of 30 lbs per square foot and the required area is 100 square feet, the total weight would be

\[ \text{Weight} = 100 \, \text{sq ft} \times 30 \, \text{lbs/sq ft} = 3000 \, \text{lbs} \]

Practical Implications

Knowing the weight of steel bar grating is vital for multiple reasons

1. Structural Integrity Engineers must ensure that supporting structures can handle the weight of the grating along with any additional loads (such as foot traffic or equipment).

2. Transportation and Handling Understanding weight helps in planning how to move and install the grating. Heavier panels may require more manpower or specialized equipment, while lighter panels can often be handled by fewer workers.

3. Cost Considerations Generally, heavier gratings may be more expensive due to the increased material usage. However, the choice should also consider performance requirements and lifespan.

4. Safety Compliance Adhering to safety standards requires an understanding of load limits, and the weight of the grating itself plays a significant role in meeting these requirements.

Conclusion

In conclusion, steel bar grating weight is a critical consideration in its selection and application. Factors such as material, bar thickness, spacing, dimensions, and coatings all contribute to the overall weight, which directly impacts structural integrity, handling, cost, and safety compliance. Understanding these factors can help in making informed decisions that not only meet the practical needs of a project but also ensure that safety and performance standards are maintained. As industries continue to evolve, the utilization of steel bar grating remains integral, making its weight an ever-relevant topic for engineers and construction professionals alike.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024