- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

steel bar grating weight

Understanding Steel Bar Grating Weight An Essential Guide

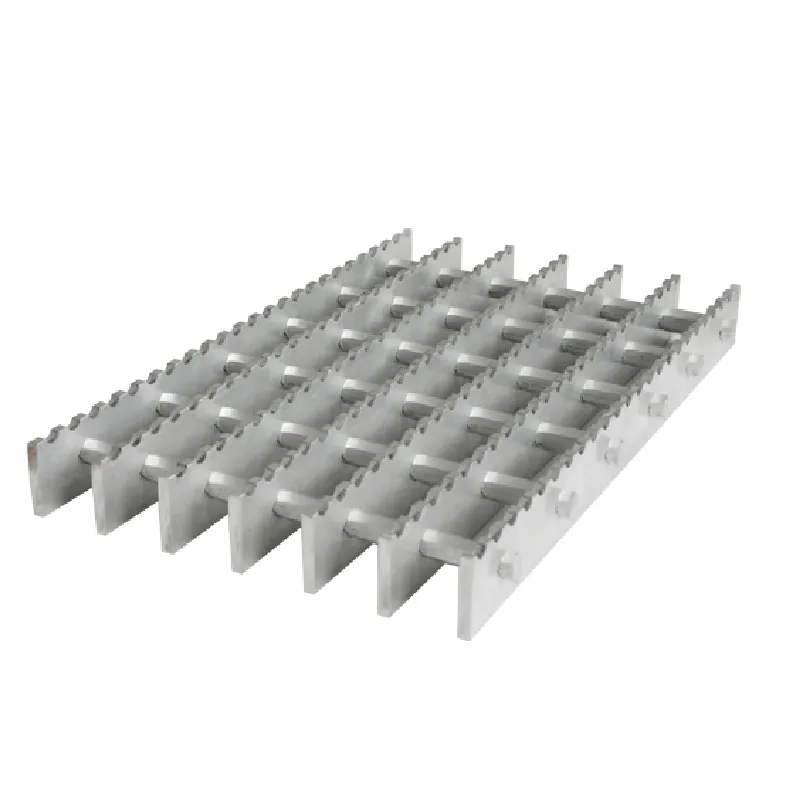

Steel bar grating is a versatile and widely used material in various industries, primarily due to its strength, durability, and ability to provide excellent drainage and ventilation. However, one critical factor that engineers and project managers must consider when selecting steel bar grating for their applications is its weight. Understanding the weight of steel bar grating is essential for several reasons, including structural integrity, load capacity, and transportation logistics.

Understanding Steel Bar Grating Weight An Essential Guide

The weight of steel bar grating is typically measured in pounds per square foot (psf) or kilograms per square meter (kg/m²). A standard piece of steel bar grating might weigh anywhere from 0.5 psf for lighter designs to over 10 psf for heavier-duty versions. This variation means that careful calculations are essential when planning any construction or installation project, especially when the grating is to be installed overhead or requires support structures capable of handling the added weight.

steel bar grating weight

When considering the weight, it’s crucial to relate it to the intended application. For instance, in industrial environments where heavy machinery frequently operates, selecting a heavier steel bar grating with a high load rating is vital. Conversely, for pedestrian walkways or light traffic areas, a lighter grating solution can reduce costs and ease installation without compromising safety.

Moreover, the weight of the grating affects transportation logistics. Heavier grating not only increases shipping costs but also requires more robust handling equipment during delivery and installation. Project managers must therefore evaluate the trade-offs between strength and weight to optimize logistics and budget considerations.

Conducting a weight analysis will also aid in determining proper support spacing. Depending on the weight distribution of the grating and any additional loads it’s expected to carry, the support structure must be adequately designed to ensure stability and safety. Typically, the spacing of girders and joists is influenced by the weight of the selected grating, making it crucial to have accurate weight figures during the design phase.

In conclusion, understanding the weight of steel bar grating is essential for achieving structural integrity and safety in various applications. It impacts load capacity, installation logistics, and overall project costs. By carefully considering the weight of the grating in relation to its intended use, engineers and project managers can make informed choices that enhance safety and efficiency, ensuring successful outcomes in their projects. Whether you’re constructing a bridge, creating a walkway, or designing an industrial platform, the consideration of steel bar grating weight cannot be overlooked.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024