- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 23:27

Back to list

heavy-duty welded bar grating

Steel bar grating sizes are a crucial consideration for various industrial and architectural applications. This article delves into foundational insights and expert opinions on selecting the appropriate sizes to maximize both function and aesthetics.

Selecting the correct grating size also involves adhering to safety standards. The Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) specify certain load and spacing specifications to ensure worker safety. Engaging with these guidelines during the selection process can prevent potential compliance issues and enhance safety outcomes. In the context of aesthetics and architectural impact, steel bar grating offers flexibility to create visually appealing designs. Its availability in various sizes and finishes allows architects to tailor solutions that meet both aesthetic desires and functional demands. For projects like pedestrian walkways, selecting a size that complements the design without compromising on safety or functionality can marry form and function effectively. Renowned industry professionals emphasize the importance of consultation with experienced engineers or grating experts. Their insights can determine the optimal size that aligns with both practical demands and budgetary constraints. It's advisable to involve these experts early in the design phase to ensure that all factors, from load ratings to environmental conditions, are thoroughly evaluated. The trustworthiness of steel bar grating suppliers is another critical factor. A reputable supplier will not only provide a broad range of grating sizes but also possess the certifications and credibility to ensure that the materials meet industry standards. Engage with suppliers who offer comprehensive support—from initial design consultation to post-installation guidance. In conclusion, the size of steel bar grating plays an integral role in its performance, safety, and aesthetic value. By understanding the intricate balance of load requirements, safety regulations, and environmental conditions, one can select the appropriate grating size that meets the specific needs of any project. The collective wisdom of industry experts, alongside collaborations with trustworthy suppliers, ensures a successful selection process that delivers long-lasting and effective solutions.

Selecting the correct grating size also involves adhering to safety standards. The Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) specify certain load and spacing specifications to ensure worker safety. Engaging with these guidelines during the selection process can prevent potential compliance issues and enhance safety outcomes. In the context of aesthetics and architectural impact, steel bar grating offers flexibility to create visually appealing designs. Its availability in various sizes and finishes allows architects to tailor solutions that meet both aesthetic desires and functional demands. For projects like pedestrian walkways, selecting a size that complements the design without compromising on safety or functionality can marry form and function effectively. Renowned industry professionals emphasize the importance of consultation with experienced engineers or grating experts. Their insights can determine the optimal size that aligns with both practical demands and budgetary constraints. It's advisable to involve these experts early in the design phase to ensure that all factors, from load ratings to environmental conditions, are thoroughly evaluated. The trustworthiness of steel bar grating suppliers is another critical factor. A reputable supplier will not only provide a broad range of grating sizes but also possess the certifications and credibility to ensure that the materials meet industry standards. Engage with suppliers who offer comprehensive support—from initial design consultation to post-installation guidance. In conclusion, the size of steel bar grating plays an integral role in its performance, safety, and aesthetic value. By understanding the intricate balance of load requirements, safety regulations, and environmental conditions, one can select the appropriate grating size that meets the specific needs of any project. The collective wisdom of industry experts, alongside collaborations with trustworthy suppliers, ensures a successful selection process that delivers long-lasting and effective solutions.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

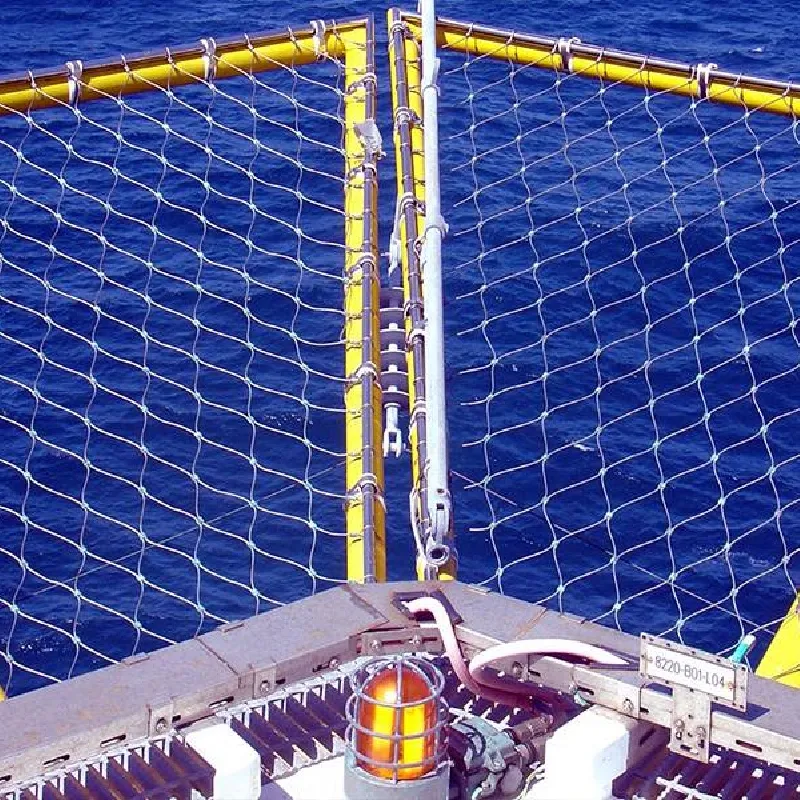

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024