- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 11:59

Back to list

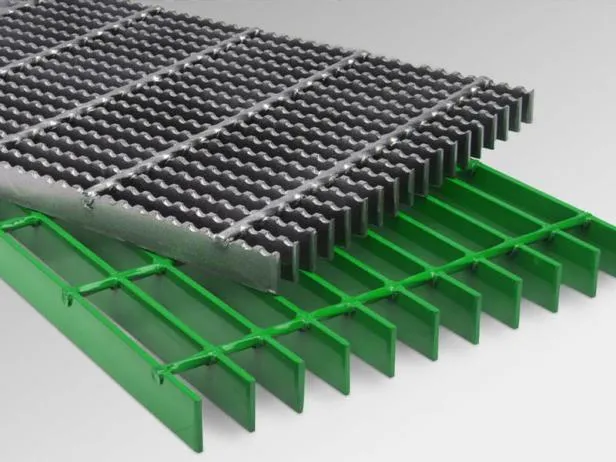

Welded Steel Grating

Steel bar grating load tables have become an essential tool in the engineering and construction industries, guiding professionals in selecting the appropriate grating for their projects. With decades of experience and a focus on safety, understanding these load tables is crucial for anyone involved in structural development.

Furthermore, environmental factors must also be considered. Gratings installed in conditions subject to ice, heat, or chemical exposure may require special coatings or treatments to maintain their load-bearing capabilities. It is crucial for engineers to account for these factors, ensuring the selected gratings perform reliably throughout their intended lifespan. Trustworthiness is key when selecting steel bar gratings. Reputable manufacturers provide verified load tables, tested and endorsed by industry standards organizations. These tables not only help in making informed decisions but also provide peace of mind, knowing that the chosen materials comply with safety regulations. Professional expertise is indispensable in interpreting these tables accurately. Engineers and construction professionals must balance the information within the load tables with practical site assessments, considering factors such as installation angles and potential dynamic loads. Misinterpretation could lead to overspending on unnecessary material or, worse, underestimation of required safety margins, which might compromise the structural integrity. In conclusion, steel bar grating load tables are indispensable in the construction and engineering sectors, offering a reliable foundation for selecting the appropriate grating materials. Their development is a testament to collective expert knowledge, combining theoretical calculations with empirical testing. As with any crucial component in construction, ensuring the authenticity and accuracy of these tables is paramount, underscoring a commitment to safety and excellence in every project.

Furthermore, environmental factors must also be considered. Gratings installed in conditions subject to ice, heat, or chemical exposure may require special coatings or treatments to maintain their load-bearing capabilities. It is crucial for engineers to account for these factors, ensuring the selected gratings perform reliably throughout their intended lifespan. Trustworthiness is key when selecting steel bar gratings. Reputable manufacturers provide verified load tables, tested and endorsed by industry standards organizations. These tables not only help in making informed decisions but also provide peace of mind, knowing that the chosen materials comply with safety regulations. Professional expertise is indispensable in interpreting these tables accurately. Engineers and construction professionals must balance the information within the load tables with practical site assessments, considering factors such as installation angles and potential dynamic loads. Misinterpretation could lead to overspending on unnecessary material or, worse, underestimation of required safety margins, which might compromise the structural integrity. In conclusion, steel bar grating load tables are indispensable in the construction and engineering sectors, offering a reliable foundation for selecting the appropriate grating materials. Their development is a testament to collective expert knowledge, combining theoretical calculations with empirical testing. As with any crucial component in construction, ensuring the authenticity and accuracy of these tables is paramount, underscoring a commitment to safety and excellence in every project.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024