- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

High-Quality Steel Bar Grating Available for Purchase Online at Competitive Prices

Understanding Steel Bar Grating An Essential Component for Industrial Applications

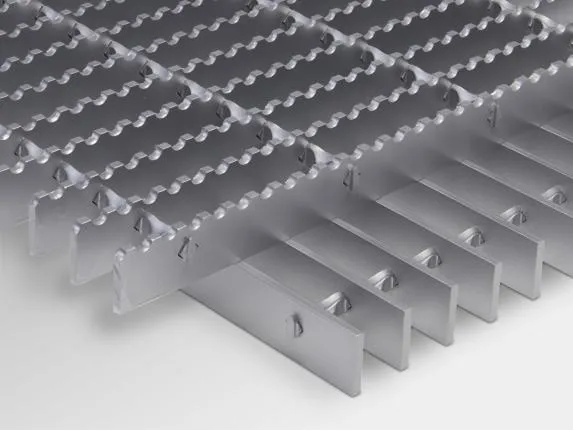

Steel bar grating is a versatile and durable material widely used in various industrial applications. With its robust construction and reliability, it serves as an essential component in flooring, walkways, platforms, and drainage covers. This article will discuss the main features, benefits, and considerations when purchasing steel bar grating for various needs.

What is Steel Bar Grating?

Steel bar grating is a type of structural grid made from flat steel bars, which are welded or riveted together to create a framework that allows for drainage while providing support. The bars can be arranged in several patterns, with the most common being the welded and press-locked types. The open design of steel bar grating allows for excellent ventilation and light penetration, making it an ideal choice for many environments.

Benefits of Steel Bar Grating

1. Strength and Durability One of the primary advantages of steel bar grating is its impressive load-bearing capacity. Made from high-quality steel, it can withstand heavy machinery and high foot traffic, making it suitable for manufacturing plants, warehouses, and industrial facilities.

2. Slip Resistance Safety is paramount in industrial settings, and steel bar grating offers great slip resistance due to its textured surface. This feature helps to minimize accidents and injuries, particularly in areas prone to spills or moisture.

3. Cost-Effectiveness Steel bar grating is not only durable but also cost-effective. Its long lifespan reduces replacement frequency, leading to lower maintenance costs over time. Additionally, its easy installation means reduced labor costs.

steel bar grating for sale

4. Versatility Steel bar grating comes in various styles, sizes, and finishes, allowing for customization to fit different applications. Whether it’s for walkways, platforms, or racks, you can find the right grating to meet your specific needs.

Choosing the Right Steel Bar Grating

When considering steel bar grating for sale, several factors should be taken into account

1. Load Requirements Understand the weight and type of loads the grating will need to support. Different thicknesses and bar spacing can accommodate various loads.

2. Environmental Conditions Consider the environment in which the grating will be placed. If it is subject to corrosive chemicals or outdoor exposure, opting for galvanized or stainless steel grating may be beneficial to prevent rust and degradation.

3. Installation Needs Assess the installation process. Some types of grating may require specific tools or professional assistance, while others can be easily installed by a DIY enthusiast.

4. Aesthetic Factors While functionality is essential, the appearance of the grating should also align with the design goals of the space. Different finishes and colors are available to enhance the visual appeal of your project.

In conclusion, steel bar grating is a powerful solution for a wide range of industrial needs, offering strength, safety, cost-effectiveness, and customization. When purchasing, carefully consider your specific application, load requirements, environmental conditions, and aesthetic preferences to ensure you select the right product. Investing in quality steel bar grating not only enhances safety and functionality but also contributes to the overall efficiency of your industrial operations. Whether you’re in construction, manufacturing, or maintenance, steel bar grating represents a reliable choice for various applications.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024