- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

steel grating specifications

Steel Grating Specifications An Overview

Steel grating is a crucial component in various industrial applications, providing essential strength and durability while ensuring safety in environments ranging from manufacturing plants to pedestrian walkways. Understanding steel grating specifications is paramount for selecting the right type for specific applications.

Material Composition Steel grating is typically made from carbon steel, which offers excellent strength-to-weight ratios. For more demanding environments, stainless steel can be utilized due to its corrosion resistance. The choice between these materials depends on the environmental conditions, such as exposure to moisture or chemicals.

Types of Steel Grating There are several types of steel grating, each designed for specific applications

. The most common types include1. Bar Grating Comprised of parallel bars welded together, bar grating is most often used in industrial flooring and platforms. 2. Fiberglass Grating Although not steel, this option is popular for its corrosion resistance and lightweight nature, often used in chemical plants. 3. Expanded Metal Grating Made from a single sheet of metal that is slit and stretched, this option provides good ventilation and light penetration, suitable for walkways and catwalks.

steel grating specifications

Load Capacity The load capacity of steel grating is a critical specification, often determined by its thickness, spacing of the bearing bars, and material type. Load classifications such as light, medium, and heavy duty are used to specify the maximum weight the grating can support. It is essential to match these specifications with the anticipated loads in the intended application.

Dimensions and Spacing Standard dimensions for steel grating include widths, lengths, and thicknesses, which can vary depending on manufacturing standards. The spacing between the bearing bars affects both the strength and weight of the grating, as well as the overall safety for pedestrian traffic.

Surface Treatment To enhance durability and resistance to wear, steel grating is often treated with various surface finishes. Options may include hot-dip galvanizing, paint, or powder coating, which protect against rust and other environmental factors.

Installation and Maintenance Proper installation is critical to ensuring the longevity and safety of steel grating. Regular inspections and maintenance can prevent issues such as warping or corrosion, maintaining optimal performance for years.

In conclusion, understanding steel grating specifications is essential for engineers and project managers when selecting the appropriate type for their applications. By considering material, type, load capacity, and surface treatment, one can ensure safety and functionality in their projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

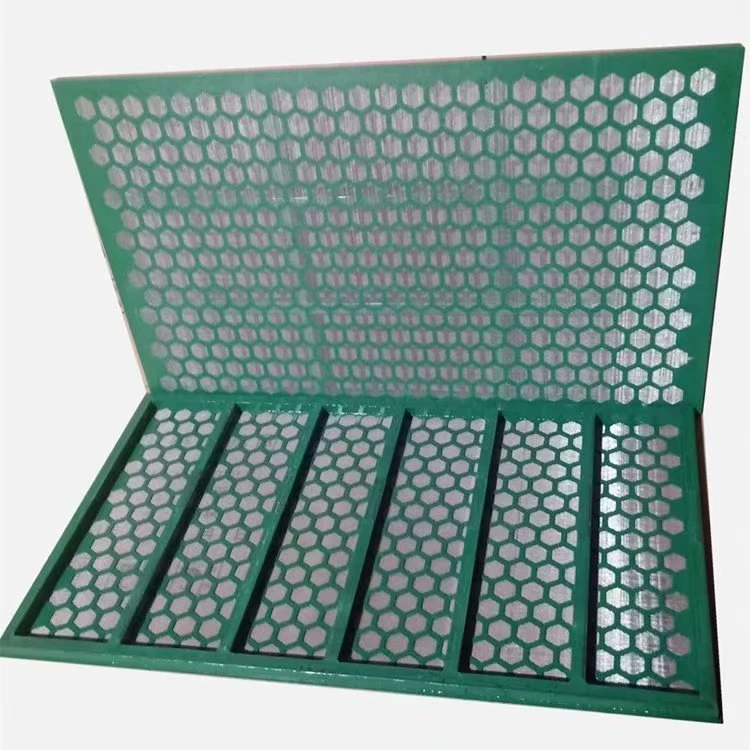

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024