- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

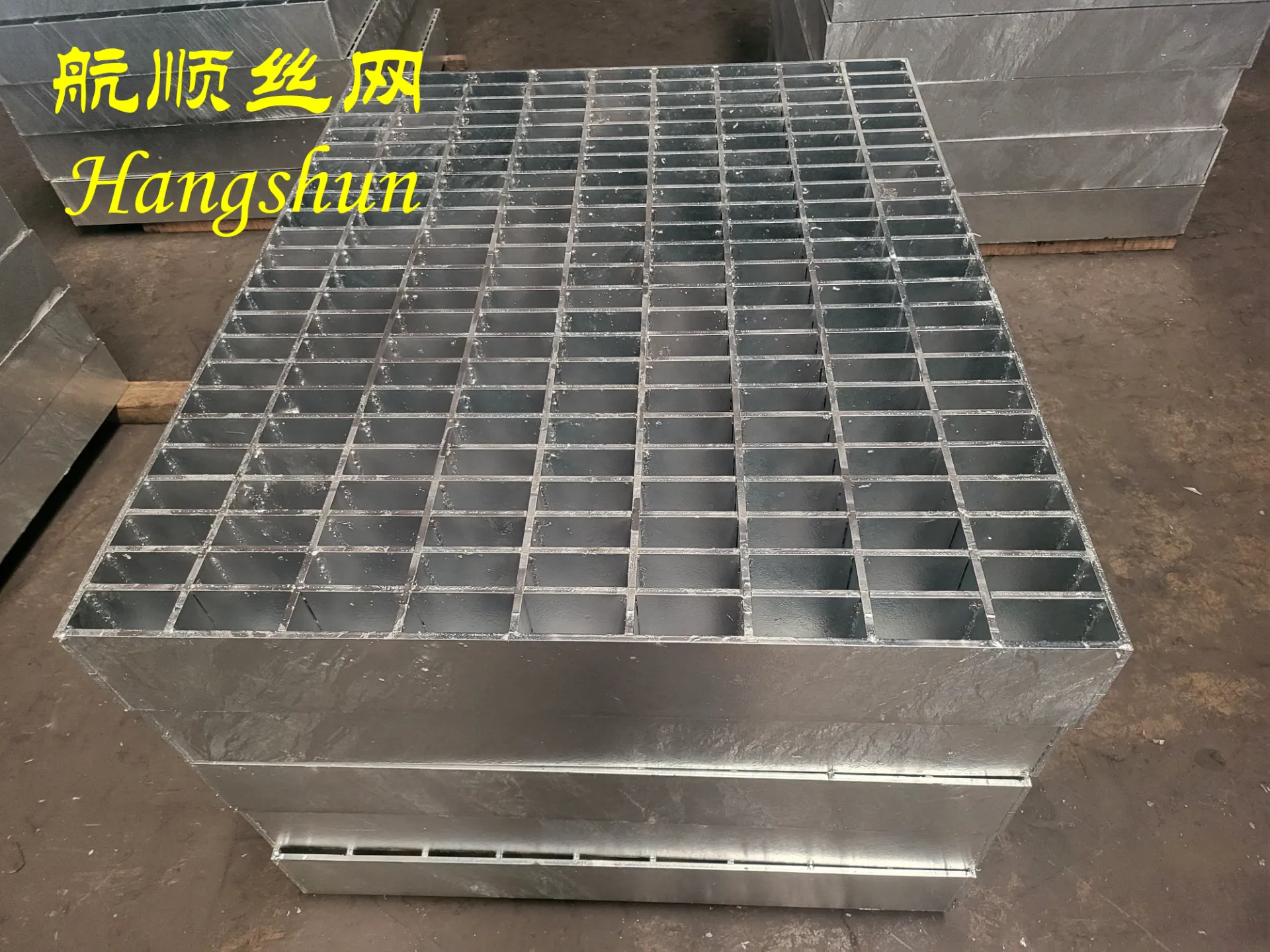

Steel Grating Maintenance: Tips for Longevity and Performance

Steel grating is a popular choice in various applications due to its durability, strength, and versatility. However, to maximize its performance and longevity, proper maintenance is essential. Regular upkeep not only extends the lifespan of steel grating but also ensures it continues to perform effectively in demanding environments. This article provides practical tips for maintaining steel grating to ensure its longevity and optimal performance.

Understanding Steel Grating

Heavy-duty mild steel grating is widely used in industrial, commercial, and architectural settings. It is known for its load-bearing capacity, slip resistance, and open grid design, which allows for effective drainage and ventilation. Commonly used in walkways, platforms, staircases, and safety barriers, steel grating must endure various environmental factors, including traffic wear, weather conditions, and chemical exposure.

Regular Inspection of Steel Grating

One of the first steps in maintaining heavy steel grating is conducting regular inspections. Regular checks help identify early signs of wear, damage, or corrosion. Inspect the grating at least once every few months, or more frequently in high-traffic or harsh environments.

During inspections, look for:

Cracks or Deformation: Check for any signs of cracks or deformation in the grating. These could indicate structural issues that need immediate attention.

Corrosion or Rust: Examine the surface for any signs of rust or corrosion, especially if the grating is exposed to moisture or chemicals.

Loose Fastenings: Ensure that all bolts, nuts, and other fastenings are secure. Loose fastenings can compromise the stability of the grating.

Cleaning Procedures of Steel Grating

Keeping steel grating clean is crucial for maintaining its performance and appearance. Regular cleaning prevents the buildup of debris, which can lead to safety hazards and reduce the grating’s effectiveness.

Remove Debris: Periodically remove any debris such as leaves, dirt, or other materials that can obstruct drainage or create slip hazards. Use a broom, vacuum, or compressed air to clean the grating.

Wash with Water: For more thorough cleaning, use a pressure washer or hose to remove stubborn dirt and grime. Ensure that any cleaning agents used are compatible with steel to avoid potential damage.

Inspect During Cleaning: While cleaning, inspect the grating for signs of damage or corrosion. This dual-purpose approach allows for timely maintenance actions.

Addressing Corrosion of Steel Grating

Corrosion is a common issue with steel grating, especially in environments exposed to moisture, salt, or chemicals. Addressing corrosion promptly helps prevent further damage and extends the lifespan of the grating.

Immediate Treatment: If corrosion is detected, treat the affected areas immediately. Remove any loose rust with a wire brush or sandpaper, and apply a rust-inhibiting primer and paint to prevent further corrosion.

Protective Coatings: Consider applying protective coatings such as galvanizing or powder coating to enhance the grating’s resistance to corrosion. These coatings create a barrier between the steel and environmental elements.

Ensuring Structural Integrity of Steel Grating

Maintaining the structural integrity of steel grating is essential for its performance and safety. Regular checks and maintenance actions help ensure that the grating remains stable and functional.

Tighten Fastenings: Periodically check and tighten any bolts, nuts, and other fastenings. Loose fastenings can lead to instability and potential safety hazards.

Replace Damaged Sections: If any sections of the grating are damaged beyond repair, replace them promptly to maintain the overall integrity of the structure.

Check Load Capacity: Ensure that the grating is used within its specified load capacity. Overloading can lead to deformation and structural failure.

Environmental Considerations of Steel Grating

Steel grating maintenance can vary based on the environment in which it is used. Tailoring maintenance practices to specific environmental conditions ensures better performance and longevity.

Moist Environments: In environments with high humidity or exposure to water, focus on corrosion prevention and regular inspections to address rust and corrosion issues promptly.

Chemical Exposure: For areas where chemicals are present, choose steel grating with appropriate chemical-resistant coatings and clean any spills or residues immediately to prevent damage.

High Traffic Areas: In high-traffic areas, pay extra attention to wear and tear. Regular inspections and prompt repairs or replacements of damaged sections are crucial.

Documentation and Record-Keeping of Steel Grating

Maintaining detailed records of inspections, cleaning, and repairs helps track the grating’s condition and manage maintenance effectively. Documenting these activities provides insights into patterns of wear and potential areas for improvement in maintenance practices.

Hangshun Wire Mesh-Your Reliable Welded Wire Mesh Manufacturer

Welded wire mesh is widely used in industrial fields. Only by purchasing from trustworthy manufacturers can quality and precision be guaranteed. Hangshun Wire Mesh is a leading manufacturer of Welded wire mesh in China, With many years of industry experience and excellent reputation, is able to be your reliable supplier. Contact us now to get more information.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024