- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

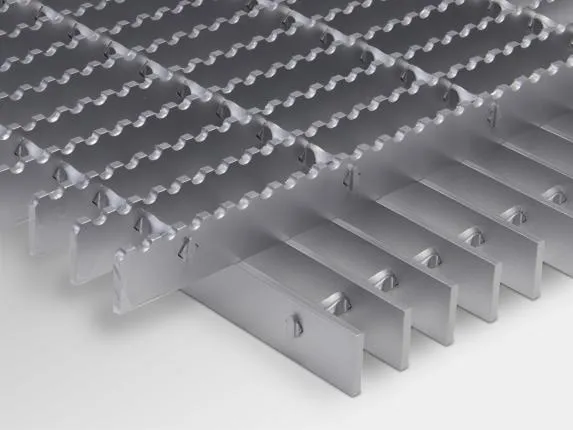

steel grating galvanis

The Benefits of Galvanized Steel Grating

Galvanized steel grating is an essential component in various industrial and commercial applications, known for its durability, strength, and resistance to corrosion. As industries continue to prioritize safety and efficiency, the use of galvanized steel grating has gained significant traction.

Understanding Galvanization

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting and corrosion. This process involves immersing the metal in molten zinc, which forms a robust layer resistant to environmental factors. The result is that galvanized steel grating can withstand harsh conditions, making it ideal for outdoor applications and in environments where exposure to moisture and chemicals is a concern.

Key Advantages

One of the primary benefits of galvanized steel grating is its long lifespan. The protective coating offers superior durability compared to uncoated steel products. This longevity translates to lower maintenance costs, as replacement or repair is needed less frequently. When choosing materials for floors, walkways, or platforms, the long-term cost-effectiveness of galvanized steel grating becomes apparent.

Another significant advantage is its slip-resistant surface. Many types of steel grating feature a welded or stamped surface projection that increases traction. This feature is particularly valuable in industrial settings, where workers may be exposed to slippery conditions. The slip-resistant qualities not only promote safety but also help in minimizing accidents and injuries on the job site.

Versatility in Applications

steel grating galvanis

Galvanized steel grating is incredibly versatile, used across various industries from construction to wastewater management. It serves as flooring in manufacturing plants, catwalks in warehouses, and even in architectural applications such as staircases and pedestrian walkways. Additionally, the open design of steel grating allows for the efficient drainage of liquids, making it ideal for environments prone to spills or flooding.

Sustainability Factor

In an age where sustainability is crucial, galvanized steel grating also stands out as an eco-friendly option. Steel is a recyclable material and can be repurposed at the end of its life cycle, significantly reducing landfill waste. The zinc coating extends the product's life, which reinforces the concept of sustainability by enabling materials to be used longer before disposal.

Installation and Maintenance

Installation of galvanized steel grating is typically straightforward, requiring minimal tooling and time. Several standard sizes and designs are available, which can be easily customized to fit specific projects. Maintenance is also minimal; periodic inspections and cleaning meetings are usually sufficient to keep the grating in good condition, highlighting its practicality for busy industrial environments.

Conclusion

Galvanized steel grating offers unmatched durability, safety, and efficiency, making it a top choice for numerous applications. Its resistance to rust and corrosion, combined with its slip-resistant properties and low maintenance requirements, underline its importance in modern industries. Furthermore, its versatility and sustainability make it not only a practical but also a responsible choice for builders and manufacturers alike. As sectors strive for greater safety standards and longevity in materials, galvanized steel grating stands ready to meet those needs, supporting a robust and secure industrial future.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024