- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Stainless Steel Grating Standards and Specifications for Industrial Applications

Stainless Steel Grating Specification Understanding Key Features

Stainless steel grating is an essential component in various industries, renowned for its durability, strength, and corrosion resistance. The specifications of stainless steel grating can significantly influence its performance, safety, and suitability for specific applications. This article delves into the key specifications and factors to consider when selecting stainless steel grating.

1. Material Composition

The primary allure of stainless steel grating lies in its material properties. Typically, stainless steel grades such as 304 and 316 are favored due to their blend of strength and resistance to oxidation and corrosion. Grade 304 is ideal for most indoor applications, while 316, with its enhanced resistance to marine environments and chemicals, is preferred for more demanding conditions.

2. Type of Grating

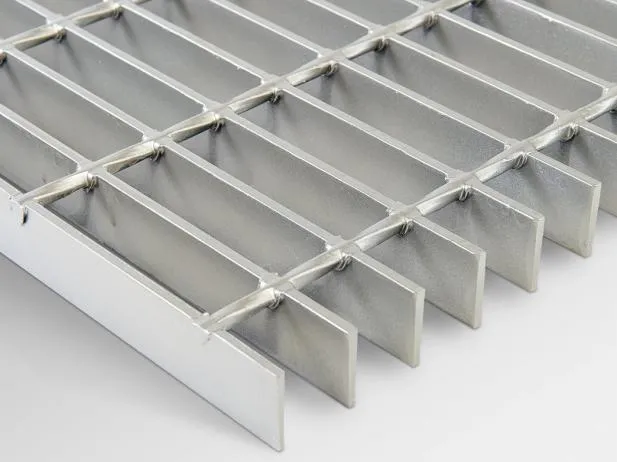

Stainless steel grating comes in various forms, including welded, swaged, and press-locked types. Welded grating, created by welding the bearing bars and cross bars, is known for its sturdy construction, making it suitable for heavy loads. Swaged grating, on the other hand, offers a lightweight yet robust option that allows for greater flexibility in design. Press-locked grating is easier to handle and install, offering a balance between strength and weight.

stainless steel grating specification

Understanding load capacity is crucial when selecting stainless steel grating for specific applications. Grating is rated according to its ability to support weight, which varies based on bar spacing, thickness, and overall design. Specifications typically include pedestrian traffic ratings, vehicular load ratings, and potential dynamic forces. Ensuring the grating can support the expected load is essential for safety and performance.

4. Finish Options

The surface finish of stainless steel grating affects both aesthetics and performance. A smooth finish can enhance cleanliness and minimize slip hazards, while a textured or serrated finish can provide extra grip in slippery environments. Additionally, various coating options, such as galvanized finishes, can enhance the corrosion resistance of grating in harsh conditions.

5. Compliance and Standards

Lastly, stainless steel grating specifications should adhere to industry standards, such as ANSI/NAAMM certification, which ensures quality, safety, and compatibility with building codes. Proper certification is essential for applications in commercial buildings, walkways, and industrial settings to guarantee performance and reliability.

In summary, selecting the appropriate stainless steel grating involves careful consideration of material composition, type, load capacity, finish, and compliance with standards. Understanding these specifications ensures that the chosen grating is not only functional and safe but also suited to the specific environmental conditions in which it will be used.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024