- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

stainless steel grating specification

Stainless Steel Grating Specification An Overview

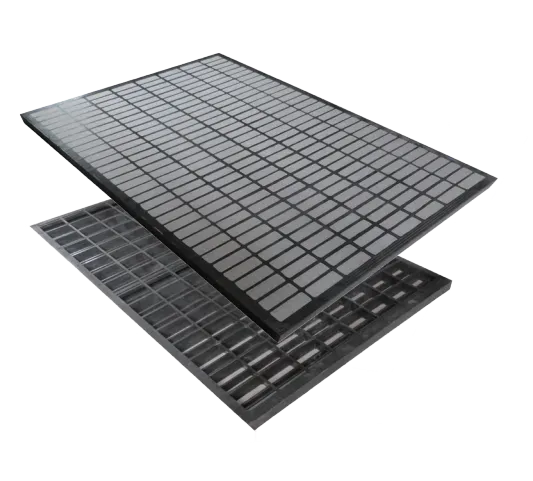

Stainless steel grating is a versatile and durable material widely used in various industrial and architectural applications. Its unique properties make it an ideal choice for environments where strength, corrosion resistance, and aesthetic appeal are paramount. This article outlines the key specifications and considerations when selecting stainless steel grating.

Material Composition

The most commonly used stainless steel grades for grating are 304 and 316. Grade 304 is known for its excellent corrosion resistance and is suitable for general applications. In contrast, grade 316 offers enhanced resistance to chlorides and is ideal for maritime or chemical environments. When choosing grating, understanding the material composition is crucial, as it directly impacts durability and performance in specific conditions.

Load-Bearing Capacity

One of the critical specifications of stainless steel grating is its load-bearing capacity. The design should meet the requirements of the intended application, which may vary significantly from one project to another. Load capacities are generally classified based on the type of grating bar grating can accommodate heavy loads, while expanded metal grating is often used for lighter applications. It is essential to consult load tables provided by manufacturers to ensure compliance with safety standards.

Grating Styles

stainless steel grating specification

Stainless steel grating comes in various styles, including welded, pressure-locked, and swage-locked. Welded grating is known for its robust construction, making it suitable for high-load areas. Pressure-locked grating provides a smooth surface and can be used in scenarios where slip resistance is desirable. Swage-locked grating is lightweight and often preferred for architectural applications due to its aesthetic qualities. Selecting the right style greatly influences the performance and appearance of the installation.

Surface Finish

The surface finish of stainless steel grating is another vital specification. Options range from unpolished to various levels of polish, including satin and mirror finishes. A polished finish provides enhanced aesthetic appeal and additional corrosion resistance, making it suitable for exposed architectural applications. On the other hand, an unpolished finish can offer better traction, making it preferable for industrial settings where slip resistance is critical.

Customization and Fabrication

Many manufacturers offer customization options, allowing projects to specify dimensions, bar spacing, and other features to fit specific needs. Custom fabrication of stainless steel grating can ensure that it meets the exact requirements of unique projects, enhancing both functionality and visual appeal.

Conclusion

Understanding the specifications of stainless steel grating is essential for achieving the desired performance and longevity in any application. By considering factors such as material composition, load-bearing capacity, grating styles, surface finishes, and customization options, designers and contractors can make informed decisions that lead to successful installations. As its popularity continues to grow across industries, stainless steel grating remains a reliable choice for both functional and aesthetic purposes.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024