- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 03:50

Back to list

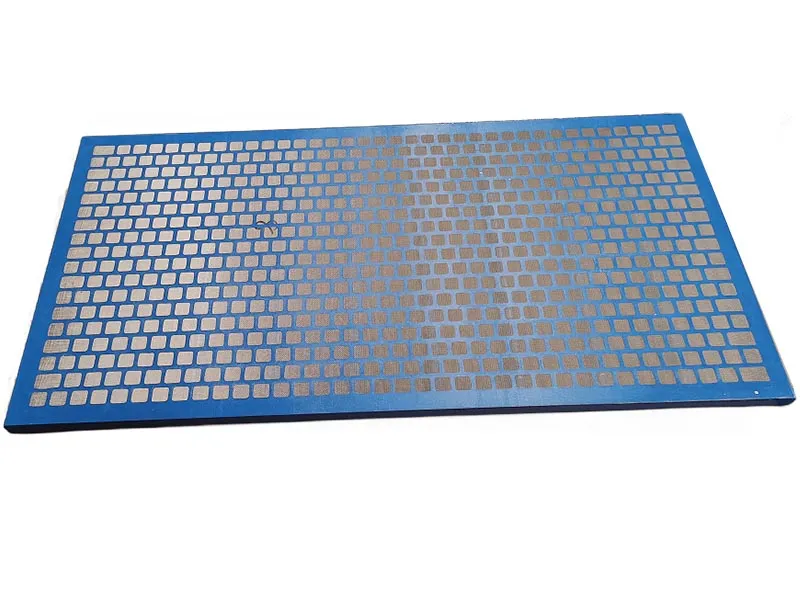

steel walkway grating

Stainless steel grating has emerged as an indispensable product for various industrial and commercial applications due to its robustness, durability, and resistance to corrosion. As a seasoned SEO specialist deeply immersed in engineering and industrial materials, the value of stainless steel grating cannot be overstated, making it a critical component in infrastructure projects around the world.

Trustworthiness is further cemented through comprehensive testing and certification processes. Leading manufacturers subject their stainless steel gratings to extensive testing, including load testing, corrosion resistance tests, and slip resistance evaluations. This rigorous approach ensures that the grating meets stringent safety and performance criteria, providing peace of mind for engineers, architects, and end-users alike. Real-world experience has proven that stainless steel grating provides a cost-effective solution when the lifespan and maintenance are considered. Although the initial cost of stainless steel may be higher than alternative materials such as aluminum or fiberglass, its longevity and minimal maintenance requirements offer substantial savings over time. Stainless steel’s corrosion resistance significantly reduces the frequency of replacements and repairs, ensuring that infrastructure investments remain economically viable throughout their lifecycle. As the demand for sustainable construction materials grows, stainless steel grating continues to gain prominence. Its recyclability aligns with global sustainability goals, making it an environmentally responsible choice for companies striving to reduce their carbon footprint. The life-cycle analysis of stainless steel demonstrates a reduced environmental impact compared to less sustainable materials, further bolstering its standing in the eco-conscious construction sector. In conclusion, stainless steel grating stands out as a multifaceted material that combines strength, safety, and sustainability. With its proven track record across various industries and applications, it represents a prudent investment for any project demanding durable materials. For engineers, architects, and procurement specialists, selecting stainless steel grating from reputable suppliers ensures compliance with safety standards, maximizes lifecycle value, and supports sustainable development initiatives.

Trustworthiness is further cemented through comprehensive testing and certification processes. Leading manufacturers subject their stainless steel gratings to extensive testing, including load testing, corrosion resistance tests, and slip resistance evaluations. This rigorous approach ensures that the grating meets stringent safety and performance criteria, providing peace of mind for engineers, architects, and end-users alike. Real-world experience has proven that stainless steel grating provides a cost-effective solution when the lifespan and maintenance are considered. Although the initial cost of stainless steel may be higher than alternative materials such as aluminum or fiberglass, its longevity and minimal maintenance requirements offer substantial savings over time. Stainless steel’s corrosion resistance significantly reduces the frequency of replacements and repairs, ensuring that infrastructure investments remain economically viable throughout their lifecycle. As the demand for sustainable construction materials grows, stainless steel grating continues to gain prominence. Its recyclability aligns with global sustainability goals, making it an environmentally responsible choice for companies striving to reduce their carbon footprint. The life-cycle analysis of stainless steel demonstrates a reduced environmental impact compared to less sustainable materials, further bolstering its standing in the eco-conscious construction sector. In conclusion, stainless steel grating stands out as a multifaceted material that combines strength, safety, and sustainability. With its proven track record across various industries and applications, it represents a prudent investment for any project demanding durable materials. For engineers, architects, and procurement specialists, selecting stainless steel grating from reputable suppliers ensures compliance with safety standards, maximizes lifecycle value, and supports sustainable development initiatives.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

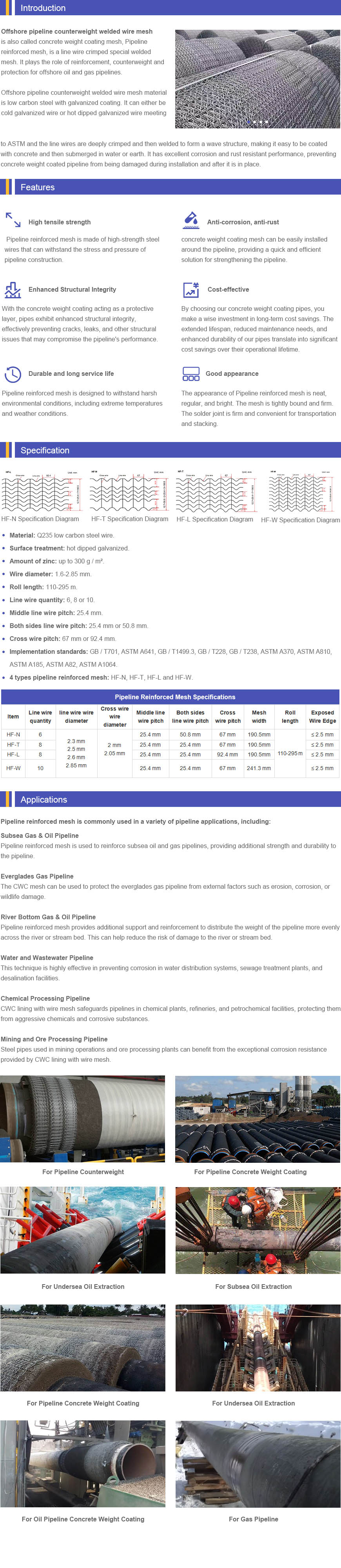

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024