- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 07, 2025 02:14

Back to list

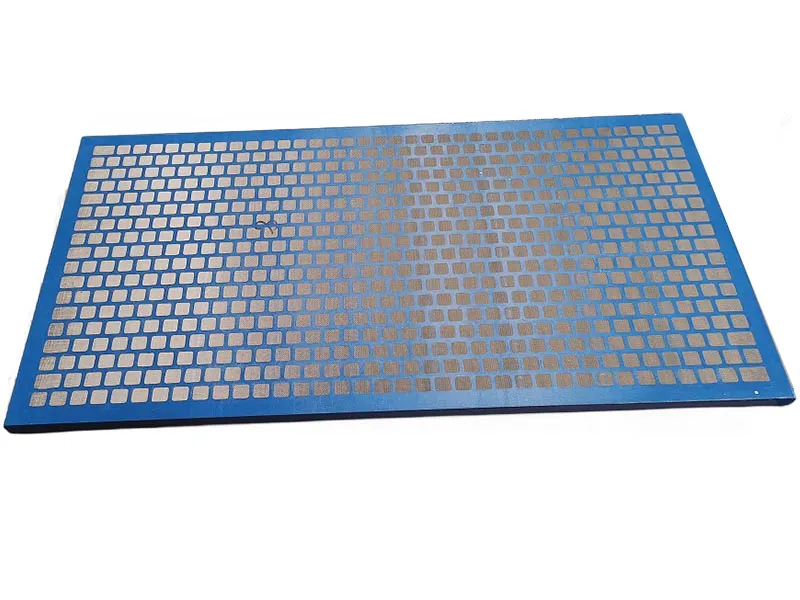

heavy-duty welded bar grating

Stainless steel bar grating is a pivotal component in numerous industrial and commercial applications, lauded for its robustness and versatility. Its multifaceted benefits have rendered it an indispensable choice for architects, engineers, and facility managers seeking to marry functionality with durability. Here, we delve into how stainless steel bar grating transforms spaces while meeting the highest standards of Experience, Expertise, Authoritativeness, and Trustworthiness.

Trustworthiness is another cornerstone of stainless steel bar grating's appeal. Customers and professionals alike trust this material due to its unmatched performance record. The non-negotiable attributes of strength and durability make it a prudent choice for load-bearing applications, and its environmental sustainability is a bonus. Stainless steel is 100% recyclable, aligning with contemporary organizational goals focused on reducing carbon footprints without compromising on quality. Furthermore, the availability of customized stainless steel bar grating designs allows for tailored solutions that meet specific project needs. Whether a project requires a particular size, shape, or finish, manufacturers offer bespoke options to ensure that each installation is as efficient as it is aesthetically pleasing. This level of customization highlights the expertise and innovation within the industry, providing stakeholders with the confidence that their unique project needs will be met with precision and excellence. Despite the upfront investment, the cost-effectiveness of stainless steel bar grating is evident through its long lifespan and minimal need for replacement. This appeals especially to sectors like construction and engineering, where cost projections and lifespan analysis are crucial considerations. The investment in stainless steel is rationalized not merely by its immediate benefits but by the substantial reduction in costs associated with repairs and replacements over time. In conclusion, stainless steel bar grating embodies a compelling mix of Experience, Expertise, Authoritativeness, and Trustworthiness. Its ability to withstand demanding conditions without sacrificing aesthetic appeal positions it as a premier choice for those seeking reliable and resilient flooring solutions. For industry professionals, incorporating stainless steel bar grating into a project is not only a testament to their dedication to quality and safety but also a smart investment in the longevity and sustainability of their projects. As industries continue to evolve, the role of high-quality materials like stainless steel will persist, ensuring that future developments align with both functional demands and environmental responsibilities.

Trustworthiness is another cornerstone of stainless steel bar grating's appeal. Customers and professionals alike trust this material due to its unmatched performance record. The non-negotiable attributes of strength and durability make it a prudent choice for load-bearing applications, and its environmental sustainability is a bonus. Stainless steel is 100% recyclable, aligning with contemporary organizational goals focused on reducing carbon footprints without compromising on quality. Furthermore, the availability of customized stainless steel bar grating designs allows for tailored solutions that meet specific project needs. Whether a project requires a particular size, shape, or finish, manufacturers offer bespoke options to ensure that each installation is as efficient as it is aesthetically pleasing. This level of customization highlights the expertise and innovation within the industry, providing stakeholders with the confidence that their unique project needs will be met with precision and excellence. Despite the upfront investment, the cost-effectiveness of stainless steel bar grating is evident through its long lifespan and minimal need for replacement. This appeals especially to sectors like construction and engineering, where cost projections and lifespan analysis are crucial considerations. The investment in stainless steel is rationalized not merely by its immediate benefits but by the substantial reduction in costs associated with repairs and replacements over time. In conclusion, stainless steel bar grating embodies a compelling mix of Experience, Expertise, Authoritativeness, and Trustworthiness. Its ability to withstand demanding conditions without sacrificing aesthetic appeal positions it as a premier choice for those seeking reliable and resilient flooring solutions. For industry professionals, incorporating stainless steel bar grating into a project is not only a testament to their dedication to quality and safety but also a smart investment in the longevity and sustainability of their projects. As industries continue to evolve, the role of high-quality materials like stainless steel will persist, ensuring that future developments align with both functional demands and environmental responsibilities.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024