- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

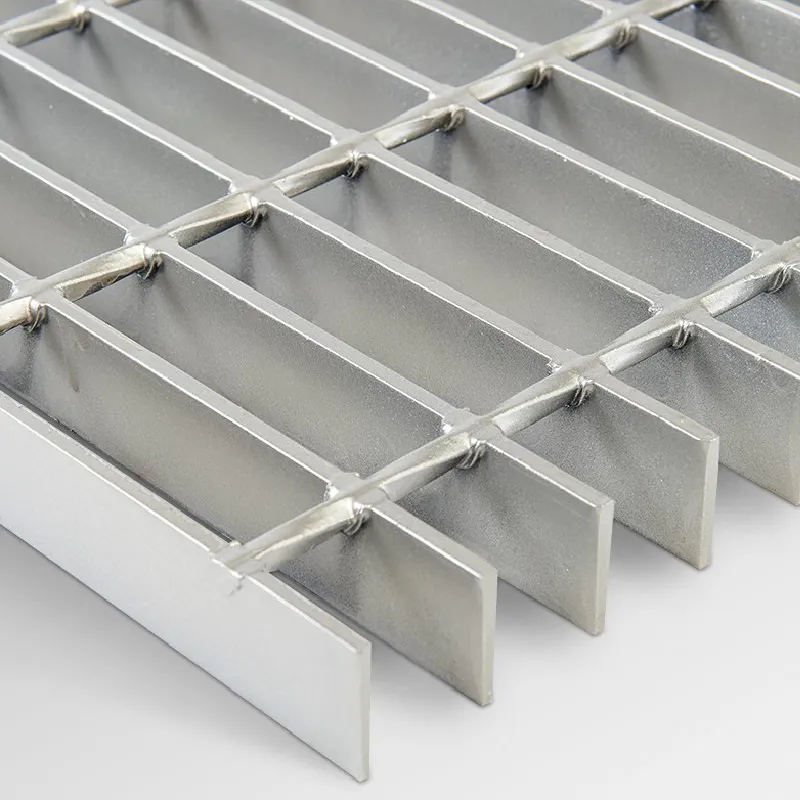

stainless bar grating

Understanding Stainless Bar Grating A Comprehensive Overview

Stainless bar grating is an essential component in various industrial applications, providing safety, support, and aesthetic appeal. Made from stainless steel, these gratings are known for their exceptional durability, corrosion resistance, and strength, making them suitable for both indoor and outdoor uses. This article aims to delve into the significance, applications, and advantages of stainless bar grating in various industries.

What is Stainless Bar Grating?

Stainless bar grating is a type of flooring or platform component composed of a series of parallel bars, spaced evenly apart. These bars are welded or mechanically locked together to create a solid framework. The most common configuration includes a series of load-bearing bars and cross-support bars, forming a grid-like pattern. This design allows for effective drainage and airflow while providing a robust surface for foot traffic or equipment use.

Key Advantages of Stainless Bar Grating

1. Corrosion Resistance One of the primary benefits of stainless steel is its inherent resistance to rust and corrosion. This makes stainless bar grating an ideal choice for environments exposed to moisture, chemicals, or harsh weather conditions. Industries such as food processing, chemical manufacturing, and wastewater treatment often utilize stainless grating to ensure longevity and safety.

2. Strength and Durability Stainless bar grating is engineered to withstand considerable loads. The structural integrity of the grating allows it to support heavy machinery, pedestrian traffic, and storage areas. Its durability minimizes maintenance costs and extends the service life of the installation.

3. Safety Features The design of stainless bar grating enhances safety in various settings. The open grid pattern allows for quick drainage of liquids, reducing slip hazards. Additionally, the surface can be treated with slip-resistant coatings to improve traction, making it safe for use in industrial environments or outdoor spaces.

4. Aesthetic Appeal Beyond functionality, stainless bar grating can contribute to the visual aspect of a space. Its sleek, modern appearance makes it a popular choice for architectural applications, including walkways, balconies, and bridges. The metallic sheen of stainless steel adds a contemporary touch to design.

5. Customization Manufacturers offer a wide variety of sizes, bar spacing options, and load ratings, allowing for tailor-made solutions to fit specific project requirements. This versatility makes stainless bar grating suitable for a wide array of settings, from industrial to commercial.

Applications of Stainless Bar Grating

stainless bar grating

Stainless bar grating finds applications across numerous industries. Here are some prominent examples

- Industrial Facilities Manufacturing plants, chemical processing facilities, and power generation stations often employ stainless bar grating for walkways, platforms, and equipment supports due to its strength and resistance to corrosive environments.

- Food and Beverage Industry The food processing sector benefits significantly from stainless bar grating. Its non-porous surface ensures sanitation and hygiene in processing areas while providing a durable flooring option.

- Wastewater Treatment In wastewater treatment plants, stainless grating is utilized on walkways and platforms due to its corrosion resistance and ability to withstand harsh environmental conditions.

- Marine Applications Boat docks, piers, and marine facilities use stainless bar grating to provide slip-resistant surfaces that endure harsh marine environments, including exposure to saltwater.

- Architectural Uses Stainless bar grating is increasingly used in building architecture for stair treads, railings, and ventilation covers, offering both functionality and style.

Installation and Maintenance

Installing stainless bar grating typically requires careful planning and adherence to safety standards. It can be custom-fabricated to fit specific dimensions and load requirements. Maintenance is minimal, primarily involving routine cleaning to ensure optimal performance and longevity. Regular inspections can help identify any wear and tear over time.

Conclusion

Stainless bar grating stands out as a versatile and reliable solution for various applications, delivering durability, safety, and aesthetic benefits. Its contribution to industries ranging from manufacturing to architecture highlights its significance in modern infrastructure. By choosing stainless bar grating, businesses can ensure a safe, functional, and visually appealing environment for their operations.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024