- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 25, 2025 04:48

Back to list

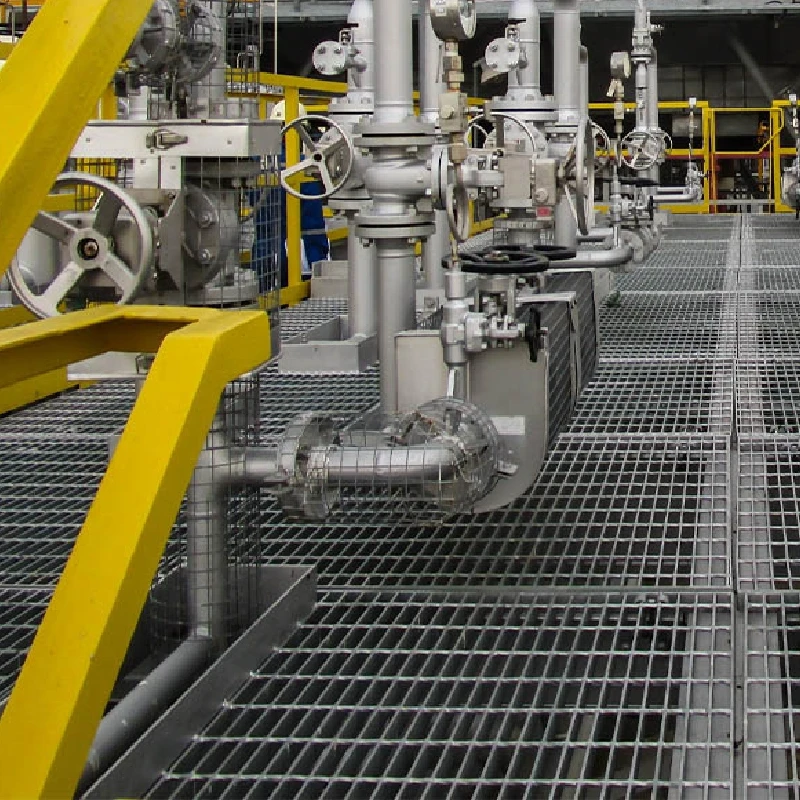

Press-Locked Steel Grating

Understanding the factors that influence the cost of SS gratings is crucial for both first-time buyers and seasoned procurement experts looking to make informed decisions. SS, or stainless steel, gratings are integral components in industrial applications, known for their durability, corrosion resistance, and robust structural properties.

Additionally, the surface treatment of the gratings cannot be overlooked as a cost determinant. Plain untreated gratings are generally less expensive; however, certain applications might require treatments such as galvanizing or powder coating to further enhance corrosion resistance, durability, or to meet regulatory standards. These additional processes contribute to higher upfront costs but may offer long-term savings through reduced maintenance and longer lifespan. Employing a reputable supplier with proven expertise and a robust track record is vital. The credibility of the supplier can influence both the quality and reliability of the product delivered, and in certain situations, an established supplier might offer comprehensive warranties and superior customer service that justifies a higher initial price. Building a relationship with reputable vendors can assure not only the quality of the SS gratings but also align with long-term procurement strategies to mitigate risks and ensure consistent delivery. Finally, bulk purchasing often provides an opportunity for cost savings. Larger orders usually enable suppliers to optimize their manufacturing processes and offer discounts due to economies of scale. Hence, aligning multiple project needs or coordinating with other departments or contractors to consolidate orders can be an effective strategy to reduce costs. In conclusion, examining the SS grating price requires an amalgamation of understanding technical specifications, evaluating material properties, considering logistical aspects, and leveraging supplier relationships. Conducting a detailed analysis on these facets helps in making informed decisions that balance cost with quality and performance, promoting efficient resource allocation and optimal project outcomes.

Additionally, the surface treatment of the gratings cannot be overlooked as a cost determinant. Plain untreated gratings are generally less expensive; however, certain applications might require treatments such as galvanizing or powder coating to further enhance corrosion resistance, durability, or to meet regulatory standards. These additional processes contribute to higher upfront costs but may offer long-term savings through reduced maintenance and longer lifespan. Employing a reputable supplier with proven expertise and a robust track record is vital. The credibility of the supplier can influence both the quality and reliability of the product delivered, and in certain situations, an established supplier might offer comprehensive warranties and superior customer service that justifies a higher initial price. Building a relationship with reputable vendors can assure not only the quality of the SS gratings but also align with long-term procurement strategies to mitigate risks and ensure consistent delivery. Finally, bulk purchasing often provides an opportunity for cost savings. Larger orders usually enable suppliers to optimize their manufacturing processes and offer discounts due to economies of scale. Hence, aligning multiple project needs or coordinating with other departments or contractors to consolidate orders can be an effective strategy to reduce costs. In conclusion, examining the SS grating price requires an amalgamation of understanding technical specifications, evaluating material properties, considering logistical aspects, and leveraging supplier relationships. Conducting a detailed analysis on these facets helps in making informed decisions that balance cost with quality and performance, promoting efficient resource allocation and optimal project outcomes.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024