- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

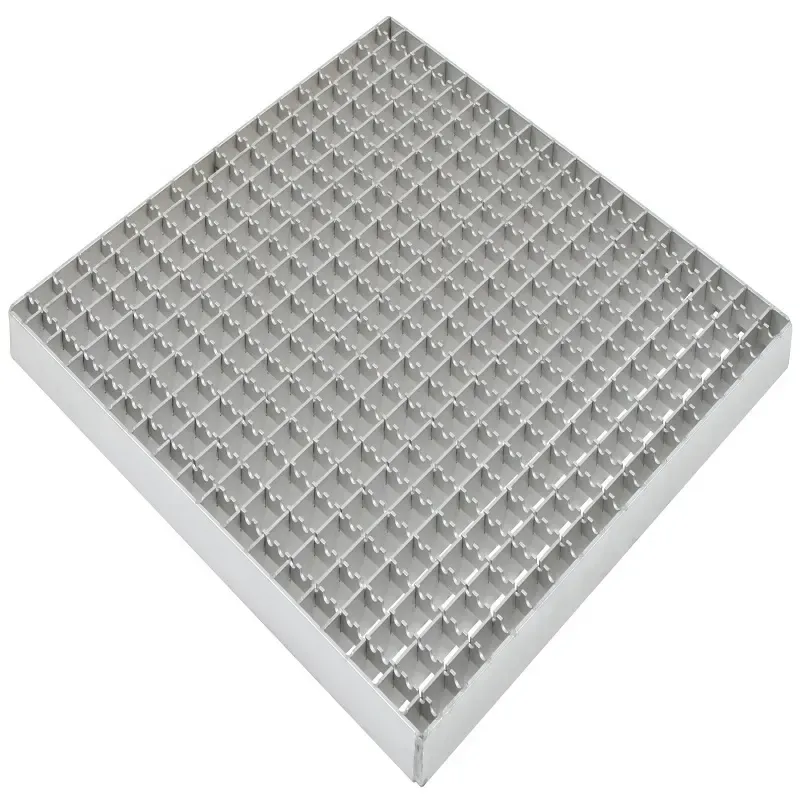

Best SS Grating Price & Stainless Steel Bar Grating Price Affordable Steel Grating Price Per Square Meter

- Introduction to ss grating price

and key influencing factors - Comprehensive overview of stainless steel bar grating solutions

- Core price drivers and worldwide market price data analysis

- Technical advantages of SS grating products explained

- Manufacturer comparison: specifications, features, and prices

- Customized solutions tailored to industrial and architectural needs

- Application cases and concluding insights on ss grating price trends

(ss grating price)

Understanding ss grating price: Key Influencers and Market Dynamics

Stainless steel grating, widely recognized for its resilience and corrosion resistance, is an essential material across industrial and architectural platforms. The ss grating price is shaped by multiple pivotal factors. These include the grade of stainless steel used (such as 304, 316), crossbar and bearing bar spacing, surface finish, and fabrication method (welded, press-locked, or swage-locked). Changes in the global nickel and chromium markets play a direct role in cost fluctuation. Competition from alternative grating materials and region-specific demand-supply dynamics also affect pricing. Likewise, volumes, customization, and value-added treatments (e.g., slip resistance, powder coating) cause variability in quotations. Consistent monitoring of raw material indices and procurement channel efficiency are thus vital for those seeking to optimise their project expenditures.

Stainless Steel Bar Grating as a Premium Solution

Stainless steel bar grating has emerged as the preferred choice for facilities that demand longevity, strength, and hygiene. It is especially popular in food processing, chemical, marine, and public works. The product’s durability results from the alloy's resistance to oxidation and wear, which keeps maintenance costs predictable over decades. There are various formats: the most common are welded and press-locked types, designed to support different load capacities and span requirements. Compared to mild steel grating, SS bar grating offers up to 5x longer life in harsh environments and drastically reduces downtime and replacement intervals. With anti-slip designs, it increases workplace safety substantially. The global demand for stainless steel bar grating continues to rise; annual market growth is projected at 4.2% through 2027, driven by upgrades in public infrastructure and regulatory demand for long-lasting materials.

Global Steel Grating Price per Square Meter: Key Data & Market Variations

Steel gratings, including stainless options, form a diverse international market where pricing per square meter exhibits notable range. Below is an at-a-glance table presenting average 2024 market data for steel grating price per square meter segmented by region and finish:

| Region | Grating Type | Material Grade | Average Price (USD/m2) | Surface Treatment | Typical Delivery Lead Time (days) |

|---|---|---|---|---|---|

| North America | Welded | SS304 | 60 - 88 | Mill Finish | 22 |

| Europe | Press-Locked | SS316 | 95 - 120 | Powder Coated | 24 |

| Middle East | Welded | SS316L | 105 - 135 | Polished | 18 |

| South Asia | Welded | SS304 | 54 - 80 | Plain | 16 |

| Australia | Press-Locked | SS316 | 110 - 155 | Brushed | 28 |

Import tariffs, shipping costs, and local regulatory standards contribute to the variance in prices above. For context, ferritic grades (e.g., 430) cost about 15-22% less but lack the durability of 304/316. Bulk purchase discounts of up to 12% are often achievable for orders exceeding 100 m2. Understanding the price per square meter helps planners balance budget and performance, especially for large projects in infrastructure, petrochemical, and commercial sectors.

Technical Advantages of SS Grating

The superiority of stainless steel grating lies in its outstanding blend of physical, chemical, and mechanical performance. SS gratings provide excellent corrosion resistance even against intense cleaning agents, seawater, and industrial effluents. With a high load-bearing capability, these gratings maintain structural rigidity on walkways, mezzanines, and rugged floor applications. In laboratory tests, welded SS gratings exhibit tensile strengths 30% higher than comparable carbon steel alternatives. Additionally, the self-cleaning nature of bar designs prevents the buildup of debris, reducing cleaning intervals. For facilities prioritizing hygiene (such as dairies or pharma plants), this is a key benefit. SS grating’s non-reactivity also supports use in zones with strict contamination controls. The material’s recyclable nature, combined with lifecycle emissions that are 55% lower than galvanized steel gratings, adds environmental value. Most products adhere to international standards such as ASTM A240 and EN 10088, ensuring uniformity and reliability in project applications.

Manufacturer Comparison: Specifications, Features, and Pricing

Selecting the right supplier for stainless steel gratings means balancing technical specifications, customization capabilities, lead times, and support provisions. Here is a comparative table of leading manufacturers with up-to-date product and pricing dimensions:

| Manufacturer | Material Grades Offered | Product Types | Max Panel Size (mm) | Certifications | Average Price (USD/m2) | Standard Lead Time (days) | After-sales Support |

|---|---|---|---|---|---|---|---|

| GrateCo | SS304, SS316 | Welded, Press-Locked | 1000 x 6000 | ISO9001, ASTM | 65 - 98 | 14-18 | 24/7; 3-year warranty |

| SteelGrid Solutions | SS304L, SS316L | Welded, Swage-Locked | 1200 x 5800 | CE, EN 10088 | 87 - 115 | 16-25 | Business hours; 2-year warranty |

| MetalsUnited | SS304, SS430 | Welded Grating | 900 x 6000 | ISO9001 | 59 - 90 | 10-14 | Email support |

| OceanGrid | SS316, SS316L | Press-Locked | 1350 x 5500 | ASTM, SGS | 110 - 135 | 22-30 | Phone & online, 24M warranty |

Variables such as available bar spacing, tolerances, post-processing treatments (e.g., anti-slip, special coatings), and ability to support complex shapes further distinguish manufacturer offerings. Customers often choose partners who can provide material traceability and batch certifications, crucial for projects in safety-critical industries.

Customized Solutions in SS Grating: From Design to Installation

Customization is a core service offered by advanced suppliers, allowing clients to address unique site requirements. Design modifications can include bespoke bar spacing, edge banding, cut-outs for piping or ducting, and adjustable load capacities. Engineering teams commonly use CAD systems to optimize patterns for safety and drainage, vital in wet or chemically aggressive zones. Recent sector trends reveal a surge in prefabricated grating panels with integrated fasteners, reducing installation times by up to 35%. For architectural uses, aesthetic treatments—like electropolishing or colored coatings—are increasingly popular. Pre-installation consultations and site measurement services are standard for top-tier suppliers, ensuring fit and minimizing on-site adaptation. Value engineering in custom projects can yield up to 22% material savings, especially when replacing conventional concrete or less durable metal flooring.

Application Cases and Final Thoughts on ss grating price Evolution

Real-world success stories exemplify the utility and cost performance of stainless steel gratings. In 2023, a leading beverage plant replaced 1,200 m2 of old galvanized walkways with SS316L grating, reporting a maintenance cost reduction of 60% and material lifespan extension from 8 to over 30 years. A Middle Eastern offshore platform equipped with press-locked SS gratings has shown zero corrosion-related downtime across five years of continuous exposure to salt spray and UV. Municipalities adopting SS grating for drainage covers cite up to 70% lower incidence of theft, thanks to higher intrinsic raw material value and traceability.

As sustainability requirements and safety codes grow stricter, the value proposition of high-quality grating is set to increase. Monitoring ss grating price trends, embracing technical innovations, and selecting partners for both product and project support underpin long-term asset reliability.

(ss grating price)

FAQS on ss grating price

Q: What is the current ss grating price per square meter?

A: The ss grating price per square meter typically ranges from $30 to $120 depending on specifications. Factors like load capacity, bar thickness, and surface finish affect the price. For accurate pricing, it's best to request a quote from suppliers.Q: How does the stainless steel bar grating price compare to mild steel grating?

A: Stainless steel bar grating is generally more expensive than mild steel, due to its superior corrosion resistance and strength. Prices for stainless steel grating can be 2-3 times higher. The extra cost is justified for environments requiring durability and hygiene.Q: What affects the steel grating price per square meter?

A: The price per square meter depends on grating material, size, bearing bar thickness, and surface treatment. Special requirements such as anti-slip finishes or custom shapes will also raise costs. Bulk purchases can sometimes lower the unit price.Q: Does the ss grating price include fabrication and installation?

A: Usually, quoted ss grating prices cover only the product cost, not fabrication or installation. Some suppliers may offer inclusive packages upon request. Always clarify with your supplier before making a purchase.Q: Where can I get the best stainless steel bar grating price?

A: Comparing prices from multiple reputable manufacturers and suppliers is the best way. Local suppliers may offer lower shipping costs, while bulk orders often come with discounts. Request detailed quotes tailored to your specific needs for the best value.-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024